A key component of reliable operations is the health of the rotating machinery within a process manufacturing or production process. Monitoring the vibration levels on this machinery is an important component in an effective reliability-centered maintenance program. I...

machinery health analyzer

Rotating Machinery Laser Shaft Alignment

Improving the reliability of your production assets requires a combination of people, processes and tools. For maintenance technician to diagnose issues during rounds portal machinery health analyzers play an important. We've shared how in posts such as Running Bump...

Hearing Machinery Reliability Issues

Sometimes your ears can identify problems with rotating machinery before investigate any further. In this 5:11 YouTube video, Audio with Parameter Alarms and Trends, Emerson's Mark Granger shows how, in addition to providing immediate colored parameter alarms bar...

Running Bump Test Helps Spot Machinery Resonance

Operating rotating equipment at resonant frequencies can damage or destroy the equipment and create dangerous situations for nearby personnel. Understanding where these frequencies may exist is critical to safe and reliable operations. In this 4:51 YouTube video,...

Detecting and Analyzing Mass Speed, Force, and Impact

When performing vibration measurements during route-based maintenance activities, different vibration measurements uncover different issues with plant machinery. In this 4:20 YouTube video, PeakVue Analysis, Emerson's Mark Granger demonstrates some of these...

Improving Safety and Efficiency in Route-Based Maintenance

When it comes to manually collecting vibration data on rotating equipment in your facility, getting it safely and efficiently is important—especially if there is a large number of assets. In this 3:54 YouTube video, CSI 2140 Speed Test, Emerson's Mark Granger and Drew...

Connecting Remote Reliability Experts with Plant Maintenance Technicians

It's been a whirlwind two weeks circling the globe—first last week in Stuttgart, Germany for the Emerson Exchange conference and then this week at our office in Manila, the Philippines. I'm back now in Austin blogging and catching up. Let's close the week with a short...

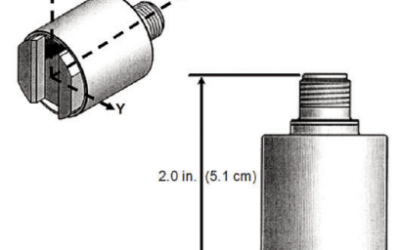

Triaxial Vibration Collection in Route-Based Machinery Monitoring

Many plants perform route-based, machinery condition monitoring with portable vibration analyzers. The most common vibration sensor used is a single-axis accelerometer mounted to a 2-pole magnet, which can easily attach to a variety of surfaces including curved ones....

Portable Vibration Analyzer-Human Centered Design Style

You may have seen the news of a next generation of portable vibration analyzer, the CSI 2140 Machinery Health Analyzer. Portable vibration analyzers are great for providing advance warning of machinery failures as part of a predictive maintenance program. The CSI 2140...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.