Most of today’s electric vehicles (EVs) rely on lithium-ion (Li-ion) batteries due to their high-energy density. As these batteries have become increasingly more advanced, so has the manufacturing process required to produce them—a complex interplay of chemical...

Posts by or with Michael Machuca

Improving Ammonia Production Sustainability

Ammonia production, a cornerstone of global food security, carries a significant environmental footprint. While its output is essential for producing fertilizers to feed billions, it accounts for 1.8% of global CO2 emissions, releasing around 500 million tonnes...

Chemical Recycling of Plastic Waste via Conversion

Only about 9% of the world’s plastic waste is recycled, according to the Organisation for Economic Co-operation and Development (OECD). Many post-consumer plastics are considered unrecyclable via traditional mechanical methods and end up in landfills, get incinerated,...

Measurement Strategies for Optimizing Fired Heaters

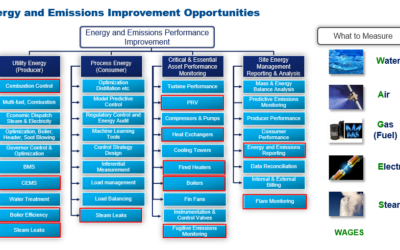

At the ACHEMA 2024 conference, Emerson’s Michael Machuca delivered a compelling presentation on Measurement Strategies to Achieve Your Sustainability and Decarbonization Goals.

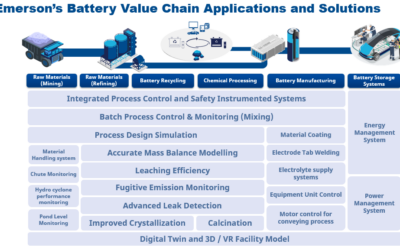

Lithium-Ion Battery Component Manufacturing Measurement Solutions

Emerson’s Michael Machuca presents Measurement Solutions for Lithium-Ion Battery Component Manufacturing at the Achema 2024, the World Forum and 34th Leading Show for the Process Industries.

Digital Solutions for Driving More Sustainable Production

At the EHS (Environmental, Health & Safety) Seminar, Emerson’s Michael Machuca presented Digital Solutions to Achieve Your Sustainability and Decarbonization Goals.

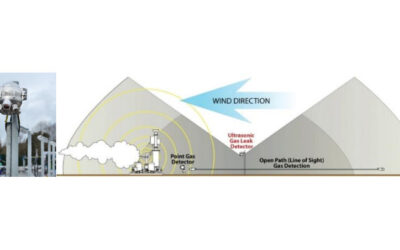

Reducing Emergency Response Times

This week at the EHS (Environmental, Health & Safety) Seminar in Galveston, Texas, Emerson’s Michael Machuca presented Digital Solutions to Reduce Emergency Response Time.

Improving Production, Safety and Reliability in Midstream Lithium Production

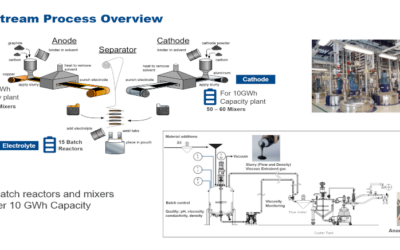

One of the challenges expressed by lithium battery manufacturers is that they have to be fast and agile because each of their customers may have different formulations for the cathode, anode, and electrolyte material.

Improving Quality in Midstream Lithium Production

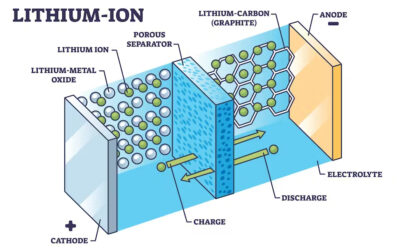

The midstream part of the lithium value chain involves manufacturing the Cathode, Anode, Electrolyte, and Separator. We will focus on the cathode, anode, and electrolyte in this series of posts. The process for making the Cathode, Anode, and Electrolyte is very similar. The process involves batch reactors and mixing.

Solving Battery Production Growth Challenges

The growth of lithium-ion battery production for electric vehicles will occur in mining, battery component manufacturing, and battery cell production from an automation standpoint.

Chemical Industry Solutions for Safety Performance Improvements

In an AIChE recorded webinar, Digital Innovations for Improving Safety in Chemical Plants, Emerson’s Michael Machuca and Marty McDonough highlight was to drive safety improvements for this important industry.

Driving Repeatable Chemical Manufacturing Batch Operations

In a recorded webinar, Achieving Repeatable Golden Batch Outcomes, Chemical Engineering magazine’s Scott Jenkins hosts Emerson’s Michael Machuca and Marty McDonough to discuss some of the automation solutions that can improve the Right First Time metric.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.