Generally, appropriate materials and coatings are the most important safeguards against corrosion. End users should carefully consider environmental conditions during material selection and preparation because good decisions in this stage will increase service life, uptime, and safety, while reducing costs.

Posts by or with Ali Babakr

Optimizing Additive Manufacturing in the Chemical Industry

In the chemical processing industries, additive manufacturing (AM) technologies have made parts production faster and less expensive, and they can be used to produce parts with more complex designs than possible with traditional manufacturing techniques.

Careful Valve Material Selection Prevents Premature Failures

In refineries and petrochemical plants, frequent contact with process media can result in premature corrosion of valves and related components. To help prevent this, vendors can provide expert advice and, in some cases, lab testing to verify compatibility between...

Controlling Corrosion as Fossil Fuels Become Increasingly Sour

In an Oil & Gas Engineering article, Emerson’s Ali Babakr and David Macedonia explain the value of NACE Standards for understanding corrosion resistance.

Following NACE Standards for Corrosion Mitigation

In an Oil & Gas article, Using NACE standards to protect against corrosion, Emerson’s Ali Babakr and David Macedonia describe ways to effectively comply with the standards to better address corrosion risks.

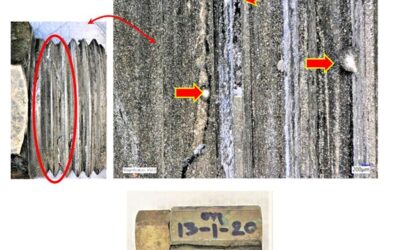

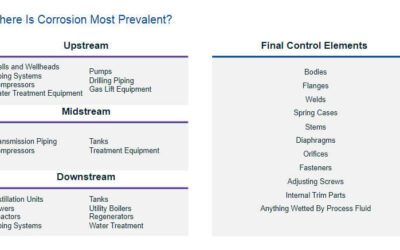

Protecting Final Control Elements in Corrosive Applications

At the Emerson Exchange Americas virtual series, Emerson’s David Macedonia and Ali Babakr describes methods of protecting final control elements in corrosive applications.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.