It isn’t news that the global pandemic upended the way we operate our plants. When social distancing trapped our most valuable personnel outside the facilities we rely on, it suddenly meant finding new ways to get critical work done.

But the reality is, those changes would have been coming—albeit less quickly—even without the influence of COVID. Retirements and shortages of experienced workers have been thinning out shift rosters for years. But, as Emerson’s Bob Lenich points out in his article Process Manufacturing’s Future is Built on Remote Solutions, there is a solution to this problem: remote monitoring. And that solution not only helps solve the problems of today, but also prepares plants for the lights-out manufacturing of the future.

Empowering Personnel

When navigating the pandemic, organizations that had begun implementing remote connectivity found they had an edge. Bob explains,

“Organizations building a remote framework leverage their digital data through secure mobile tools to ensure key personnel receive real-time, intuitive alarm notifications on their mobile devices. Persona-based alerts provide constant awareness of plant and process health, even when users cannot be on site.”

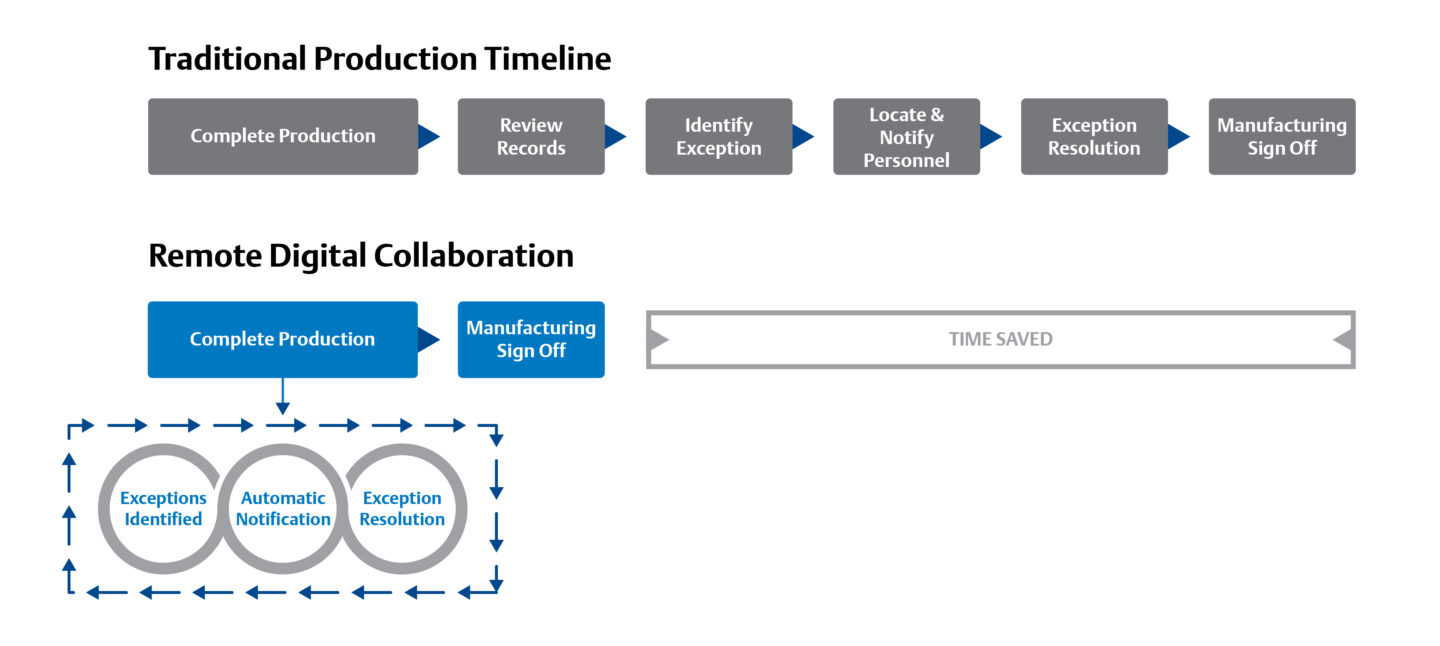

And with tools such as electronic batch record systems, manufacturing and quality assurance teams can perform tasks such as review or sign off from anywhere, eliminating the risk that they will delay product release. Remote production strategies can be completed off site and in parallel to help unlock speed to market.

Remote digital collaboration dramatically shortens project timelines

Improved Production and Performance

Operating with fewer people did not remove the need for organizations to successfully complete capital projects and process improvements.

“The need for new treatments and vaccines did not go away, so these organizations leveraged remote solutions to continue innovating.”

Remote technologies paved the way for organizations to continue innovating, even when it was difficult to bring all the necessary experts together. Simulation and cloud engineering technologies were central to success.

“Digital twin simulations create replicas of the manufacturing environment, allowing testing of new equipment and strategies without the need to access live equipment. Hosting these simulations in the cloud further empowers personnel to contribute, allowing process developers to test new control strategies from on the plant floor, in the company headquarters, or even from home or another plant across the globe.”

Unlocking Lights Out Manufacturing

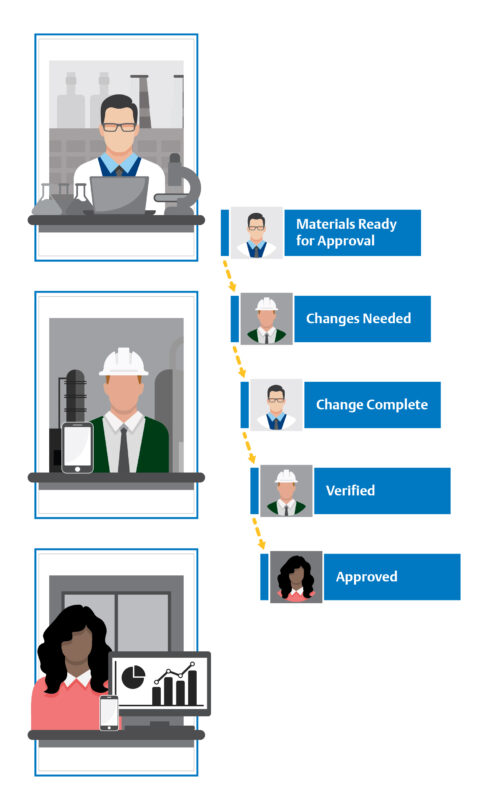

The tools life sciences organizations use to keep operating efficiently and effectively despite staffing shortages are the same tools building a foundation for new horizons of remote maintenance and operation. Remote connectivity enables key personnel from around the globe to collaborate and bring new products to market more quickly.

“The digital foundation supporting basic remote monitoring can also be expanded, empowering both manufacturing and quality assurance teams to monitor exceptions and determine whether those exceptions have an impact on the final product. Then, using digital tools such as electronic batch record systems, the same personnel can review and sign off from wherever they are, reducing the risk that quality assurance steps will delay product release.”

Using remote technologies, key personnel can contribute to production success from anywhere in the world.

As methods for keeping production running even when key personnel are away from the plant gain more and more traction, life sciences organizations further unlock ways to distance physical manufacturing from human intervention to reduce errors and potential for contamination. Bob explains how these fully-automated production environments are linked to remote monitoring technologies,

“As more areas of treatment production incorporate robotics to create fully-clean manufacturing environments, the foundation of remote technology will become even more essential to avoiding production interruptions. Inserting human contact into these clean environments for inspection, adjustments, or maintenance has the potential to create lengthy stoppages, both for the work itself and for cleaning the facility to ensure no contaminants are left behind. These stoppages will make it very hard to hit the increased production benchmarks continuous autonomous manufacturing will unlock.”

Many of Emerson’s innovative solutions, from Syncade Electronic Batch Records to DeltaV™ Mobile are designed from the ground up with remote access and collaboration in mind. A wide range of Emerson solutions can help you engineer and implement the remote monitoring foundation you’ll need for autonomous manufacturing.

You can learn more about the ways remote monitoring is changing life sciences manufacturing by reading the whole article at Processing Magazine. And while you’re here, feel free to tell us about the unique ways you’re using remote technologies to enhance your manufacturing process in the comments below.