A North American refinery was facing challenges with their crude unit charge heater due to clogging and freezing of its impulse lines. In settings like this, it’s crucial to have dependable and redundant measurement to guard against damage to the heaters and keep everything running safely and smoothly. These measurements were part of Safety Instrumented System (SIS) loops that trip if fluid levels become too low to manage the heat. Unfortunately, previous technology required impulse lines that would plug with inorganic salt byproduct or freeze from cold ambient temperatures, escalating maintenance costs, and risking rupture of the heater tubes. A Rosemount™ Quad Vortex Meter fixed the problem, making it easier to ensure plant safety and cut down on unnecessary maintenance costs.

A North American refinery was facing challenges with their crude unit charge heater due to clogging and freezing of its impulse lines. In settings like this, it’s crucial to have dependable and redundant measurement to guard against damage to the heaters and keep everything running safely and smoothly. These measurements were part of Safety Instrumented System (SIS) loops that trip if fluid levels become too low to manage the heat. Unfortunately, previous technology required impulse lines that would plug with inorganic salt byproduct or freeze from cold ambient temperatures, escalating maintenance costs, and risking rupture of the heater tubes. A Rosemount™ Quad Vortex Meter fixed the problem, making it easier to ensure plant safety and cut down on unnecessary maintenance costs.

Challenges of Heater Pass Flow Measurement at the Refinery

The first step in processing petroleum is crude oil distillation. The crude oil distillation unit is used to separate the oil into various fractions with different boiling points. First, the oil is mixed with water and heated in a desalting cycle. The desalted crude is put through a crude heater before being sent to the main atmospheric column to be distilled into different product streams like kerosene, diesel, and naphtha. This preheating step is important to ensure high enough temperatures going into the bottom of the distillation unit.

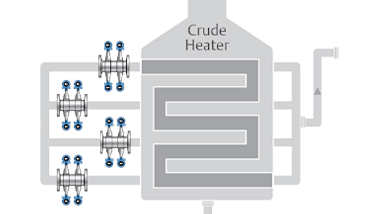

The temperature and pressure of feed lines into the multi-pass furnace are closely monitored for safety and operational efficiency. In the case of this refinery, flow meters were placed on four feed passes into the heater. These measurements were part of SIS loops to ensure adequate flow into and out of the heat exchange network. If the flow is ever slowed or stopped altogether, it’s not stabilizing the temperature, and the heater tubes could rupture. When these tubes rupture, there are significant safety concerns and high costs in the form of repair, replacement, and process upsets.

Why Legacy Technology Encountered Issues

Initially, the refinery was using a single orifice plate with four transmitters on each of the four feed passes into the heater. The differential pressure (DP) flow meters faced challenges in this environment because the impulse lines would clog, causing the transmitters to signal “no flow” when there was adequate liquid in the lines, which could needlessly trip the SIS system. Unfortunately, steam tracing was also impractical in this setting, which meant the impulse lines were subject to freezing as well. All these issues added up to additional headaches for operators as they spent time and resources performing extra maintenance on the lines.

Enter the Rosemount Quad Vortex Flow Meter

A rock star of steam measurement capabilities, one Quad Vortex Flow Meter was installed on each of the four lines going into the crude charge heater. The vortex meter’s four independent sensors and transmitters in each meter body enabled the necessary 2oo3 voting for each SIS loop. With a gasket-free, non-clog design and no impulse lines, maintenance issues dropped significantly. Wireless, remote functionality meant that the refinery had more process control and easier access, despite the hard-to-reach location. If the sensors ever need to be replaced, Rosemount Vortex meters’ isolated sensor configuration makes switching them out without disrupting operations a snap.

Need a demonstration or more information on vortex technology? Contact your local Emerson expert today. Learn more at www.Emerson.com/RosemountQuadVortex