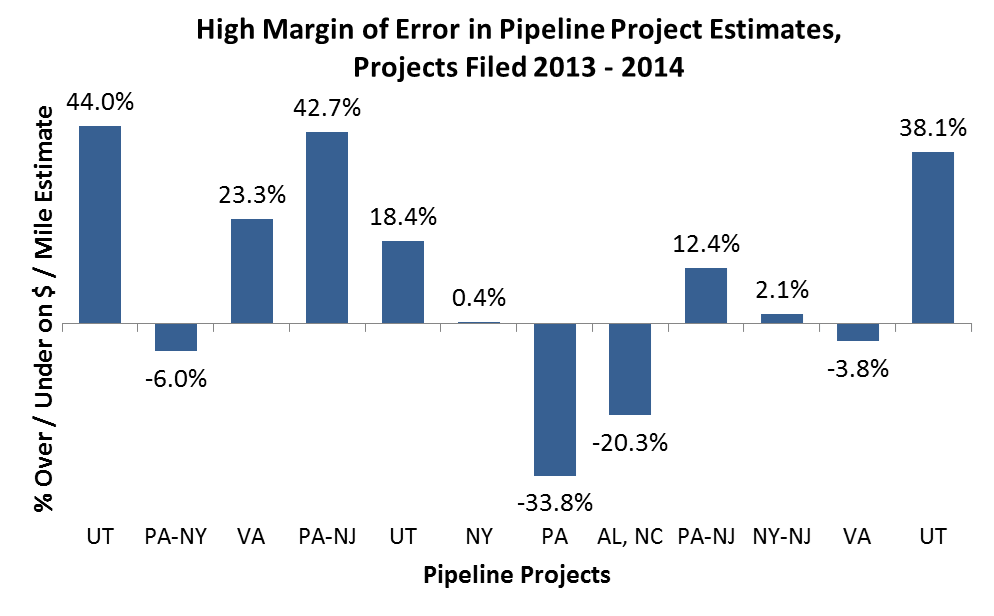

In 2014, midstream companies saw their actual project costs miss their estimates by more than 40%. On average, projects that overran their costs did so by 20.2%.1

Unplanned downtime is the same kind of issue. As much as 90% of the maintenance performed by U.S. manufacturers is reactive. Companies that have successfully tackled that problem have reduced their maintenance spend by 50% or more.2

In an industry where unpredictability is a major challenge, what can you count on? Actually, you can count on Emerson Rosemount Vortex Flow Meters – to deliver the availability, reliability and flow metering you need, whether that’s by installing the 8600 Utility™ Vortex in clean fluid applications such as steam, air, water and nitrogen or the 8800 Process™ Vortex in demanding applications like steam injection, oil refining and chemical processing.

Vortex meters have no moving parts, which translates into an economic solution that provides accurate measurement over a wide flow range. What sets the 8800 Series Vortex Flow Meters apart from other flow meters is their gasket-free, all-welded meter body, which eliminates ports and prevents leaks. Considering that about 1.5% of methane (at least 21 times more problematic than CO2) gets leaked during production, transmission and storage before it reaches consumers, every opportunity to reduce fugitive emissions is advantageous to people and the environment.3

Preventive maintenance isn’t the only way to increase availability. Rosemount Vortex Flow Meters are equipped with internal meter verification, which enables troubleshooting without stopping processes, the ability to simulate flow, and test the meter’s signal strength. That’s information that you can use to make good decisions and plans.

And let’s not forget highly accurate flow and temperature measurement.

There’s more you can be sure about with Emerson’s Rosemount Vortex portfolio. We’ve put together this infographic to show you at a glance and given you more details in this playbook.

One other thing you can do is use our new Flow Solutions Technology Advisor to determine whether Coriolis, differential pressure, vortex, turbine or ultrasonic meters are the right solution for your industry and application.