NOx is probably the most ubiquitous combustion-created air pollutant since it can be generated by any process burning any fossil fuel, and it is tightly regulated by the U.S. EPA and other regulatory bodies around the world. Plants with relevant combustion processes, including most refineries and chemical processing plants, must monitor NOx output continuously any time fuel is burning. How plants choose to do this is up to them, provided the chosen method can meet the strict regulatory requirements for accuracy and availability.

NOx is probably the most ubiquitous combustion-created air pollutant since it can be generated by any process burning any fossil fuel, and it is tightly regulated by the U.S. EPA and other regulatory bodies around the world. Plants with relevant combustion processes, including most refineries and chemical processing plants, must monitor NOx output continuously any time fuel is burning. How plants choose to do this is up to them, provided the chosen method can meet the strict regulatory requirements for accuracy and availability.

In this article in Hydrocarbon Processing, Katherine Williams and I compare and contrast two commonly used NOx measuring technologies: chemiluminescence detection (CLD) and direct absorption spectroscopy. The former measures just NOx, while the latter can measure a whole range of pollutants. Here are the mechanics of both.

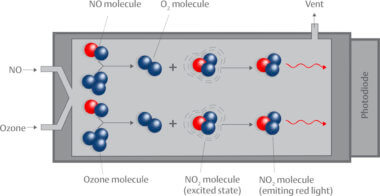

A CLD analyzer determines the amount of NOx in a sample by measuring the light given off by excited NO2 molecules.

The first measurement method depends on a chemical effect called chemiluminescence. As the result of a chemical reaction of the intermediates NO and ozone (O3), NO2 is produced in an excited energy state form. By emitting a photon in the excited state, the NO2 returns to its ground state. The light emission, or chemiluminescence, can be detected and measured, and based on the amount of light emitted, the number of NO molecules can be determined.

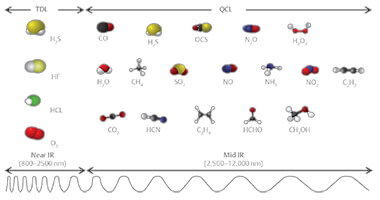

QCL/TDL systems include high-resolution lasers to measure both the near- and mid-infrared spectral regions for real-time gas analysis down to sub-ppm concentrations.

This second measurement method uses an entirely different approach. Direct absorption spectroscopy utilizes a given compound’s capability to absorb specific wavelengths of electromagnetic radiation. The absorption at a given wavelength is measured, allowing an analyzer to detect and quantify the presence of various compounds of interest. Using this technology, a single analyzer can monitor a range of pollutants in a gas stream.

Emerson’s Rosemount CLD Continuous Gas Analyzer is a single-purpose solution for NOx, and it has a proven track record for surpassing the EPA’s performance requirements for accuracy and availability. Its very wide user-selectable NOx measurement ranges (from 0-5 parts-per-million (ppm) up to 10,000 ppm) make it a versatile solution. It can be used not only in industrial combustion applications but also in gas purity measurements in medical, industrial, and food and beverage applications. Among the various NOx measurement technology alternatives, CLD technology offers reliable performance at excellent value.

But, if the application calls for monitoring other pollutants in addition to NOx, Emerson’s Rosemount CT4400 Continuous Gas Analyzer uses hybrid quantum cascade laser and tunable diode laser (QCL/TDL) technology to quantify multiple gases. In years past, this capability would have normally required an assortment of analyzers, but many applications can now be handled by a single analyzer.

Compared to older technologies, these analyzers are more reliable, more stable, easier to operate, and require no consumables. However, a large number of Continuous Emissions Monitoring Systems (CEMS) still run older analyzers with high operating costs and low availability, putting operators at risk of costly fines and shutdowns for failing to meet regulatory requirements.

Enhance your ability to meet changing environmental regulations. Read the article for more information on two different approaches for continuous NOx measurement. You can also visit the Gas Analysis Solutions pages at Emerson.com for more on the technologies and solutions to help you reduce monitoring costs and avoid fines. To connect and interact with other environmental teams in the Refining and Chemical groups, visit Emerson Exchange 365 community.