I heard a great story from Emerson’s Sam Thiara of a polymer producer in the Middle East region that was looking to improve energy efficiency across the facility’s steam system. They wanted to reduce energy costs and their carbon footprint, while also improving the stability and reliability of the process.

The plant staff worked with Emerson industrial energy consultants to benchmark existing operations. The process included staff interviews, data collection and observations. This input gathering process was followed by data analysis, rigorous simulations, and generation of a report.

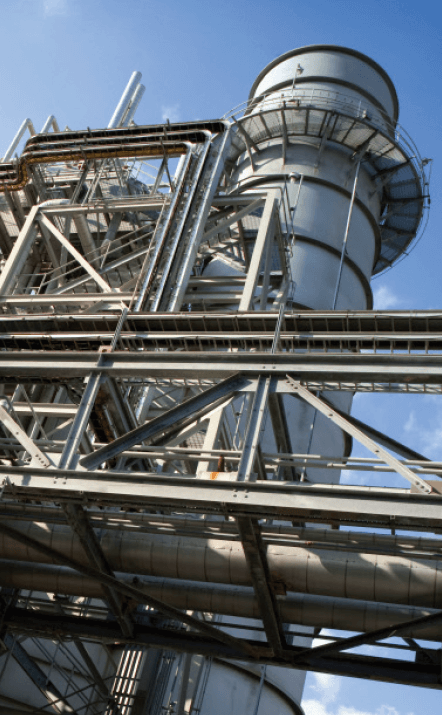

For the petrochemical products produced at this plant, large quantities of energy are consumed in the forms of mechanical power needed to drive the pumps, blowers, and compressors, and steam needed for heating the various process streams.

A majority of the steam is not controllable as it is generated in the cracking furnaces. This majority is used for process heating purposes and converted into mechanical energy for the compressors, pumps and blowers.

A majority of the steam is not controllable as it is generated in the cracking furnaces. This majority is used for process heating purposes and converted into mechanical energy for the compressors, pumps and blowers.

The largest losses came from the turbine condenser. To minimize these losses, the optimum steam routing strategy was to maximize the steam flow through the turbine high pressure sections. Maximizing this steam flow was difficult due to the complexity of the steam system and interacting control loops which were causing oscillatory behavior when operating in automatic mode.

The turbine condenser losses could not be totally eliminated due to the high shaft power requirement of the compressors, but the dump condenser heat losses could be almost completely avoided.

Given these challenges and opportunities, the consulting team performed a cost-benefit analysis and recommended the following actions:

- Conduct detailed assessment of the steam metering system

-

Implement base control and instrumentation improvements

- Inspect, calibrate, and repair (if needed) of all instruments relevant to the solution. In particular, the steam turbine flow and pressure measurements should be inspected

- Install mass flow meters for the auxiliary boiler fuels

- Linearize all letdown station valves

- Verify of proper functionality of the letdown station temperature controls

- Implement coordinated multi-variable model predictive controller (MPC) and optimization solution for the steam system

- Implement an Energy Management Information System

By improving control, optimization and the energy information system, the plant staff could improve overall operational reliability, reduce operator interventions in controlling the process, lower energy costs, reduce emissions and improve overall awareness of energy consumption levels.

Reliability improvements of the steam would occur through lower process variability and reduced wear and team on the steam system components. Coordinating these controls also provides better response to large process upsets and reduces the risk of cascading trips. Improved visibility to energy flows also enables early warning of fouling and mechanical issues to address before an unscheduled outage might occur.

Specific to the metering system, several conflicting, questionable, or missing measurement points were identified. Gaps in the metering system were noted along with existing instruments needing corrective actions, including shop inspection, calibration, repair, and in some cases, replacement.

Through this analysis and recommended solution, the team identified the possibility of greater than 15% reduction in natural gas consumed by the process. The project is currently approved and underway.

Visit the Energy & Emissions section on Emerson.com for more on the solutions and technologies to improve performance and reliable operations. You can connect and interact with other energy management and experts in the Services group in the Emerson Exchange 365 community.