Because they directly touch the process flow, control valves play a significant role in the stability, robustness and variability in the process. One bad-acting control valve can create large problems for safe and reliable operations.

At last week’s AIChE Spring Meeting, Emerson’s James Beall presented Specifying Control Valve Performance to Achieve Desired Process Performance. In his comprehensive presentation, he discussed the importance of proper valve performance, standards & references, dead band and resolution, response time, loop gain, valve troubleshooting tips, specification tips for valve performance and some examples where improvements have yielded significant business results.

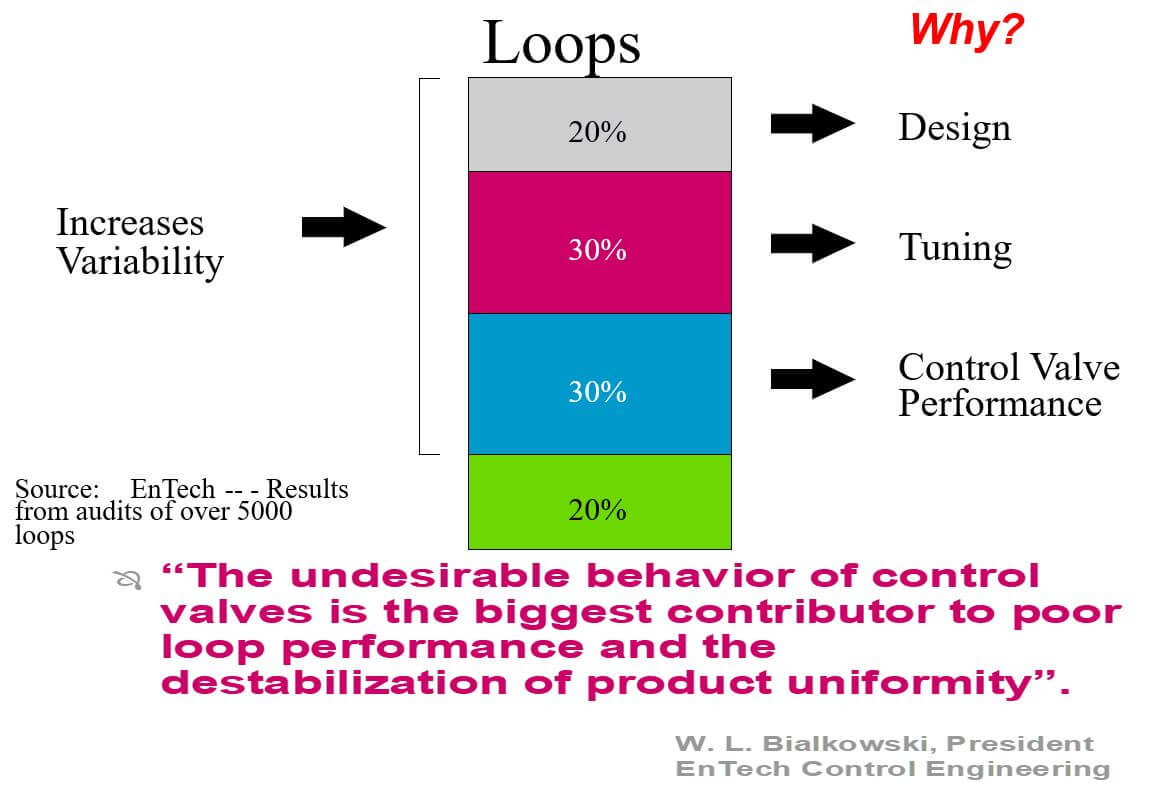

James opened citing a study of over 5000 control loops performed at the time by Entech Control Engineering. The results were that the undesirable behavior of control valves is the biggest contributor to poor loop performance and the destabilization of product uniformity. For control loops with excessive variability, 30% were caused by the performance of the control valve.

James opened citing a study of over 5000 control loops performed at the time by Entech Control Engineering. The results were that the undesirable behavior of control valves is the biggest contributor to poor loop performance and the destabilization of product uniformity. For control loops with excessive variability, 30% were caused by the performance of the control valve.

He related an example of an LNG plant’s main gas feed flow loop with a $1 million USD control valve modulating the natural gas flow into the plant that had to stay in manual operating mode due to high process gains amplifying non-linearities in the valve. The trend charts showed a square wave on the process variable and triangle wave on the control loop output to the valve indicating motion non-linearity in the control valve. One the valve motion issues we’re addressed, the control loop could return to automatic mode, for more stable and reliable operation of the entire plant.

James shared other examples of poor control valve performance in a steam valve at a vitamin plant and another steam valve in a chemical plant. He cited the ANSI/ISA S75.25 standard – Test Procedure for Control Valve Response Measurement from Step Inputs and the technical report, ANSI/ISA–TR75.25 – Control Valve Response Measurement from Step Inputs as good references for determining control valve performance.

The tool that he and the Emerson Control Performance consultants use, the Entech Toolkit, aligns with the ANSI/ISA 75.25 standard and provides guidance to measure control valve performance. This guidance includes definitions for deadband—the range through which an input signal may be varied, with reversal of direction, without initiating an observable change in output signal, resolution—the smallest step increment of input signal in one direction for which movement of the output is observed, and step response time—the interval of time between initiation of an input signal step change and the moment that the response of a dynamic reaches 86.5% of its full steady state value. The step response time includes the dead time before the dynamic response.

With these definitions, he shared some scenarios to diagnose performance issues. For a slow response of control valve, due to slow response of valve positioner that causes cycling of process variable (PV), the solution may be to simply retune the digital positioner. If this cycling is caused by the slow response of a pneumatic valve positioner, it’s best to replace it with a high-performance digital positioner. Excessive dead band and resolution can also cause cycling. These issues may be resolved by a high-performance digital positioner and/or modifications to the valve itself. As shown in the first example, James notes that a high valve process gain amplifies the position non-linearities and a change in the valve type, trim size and/or characteristics will solve this issue.

The ANSI/ISA 75.25 standard defines 4 response time regions of movement:

- Region 1 is defined as small input steps which result in no measurable movement of the closure member within the specified wait time. (This is in the region of dead band and resolution.)

- Region 2 is defined as input step changes which are large enough to result in some control valve response with each input signal change, but the response does not satisfy the requirements of the specified time and linearity.

- Region 3 is defined as step changes which are large enough to result in flow coefficient changes which satisfy both the specified maximum response time and the specified maximum linearity. (This is the range of typical control moves)

- Region 4 is defined as input steps larger than in region 3 where the specified magnitude response linearity is satisfied but the specified response time is exceeded. (This is typically caused by velocity limited operation.)

Regions 1 and 2 are bad for control performance. Region 3 provides the most linear operation of the valve and hence the best control performance. Region 4 (large step, slow or velocity limited) is typically inconsequential to control performance except in special cases like anti-surge control. The goal is to minimize the size of Region 1 and 2, maximize the size of Region 3.

When specifying control valve performance, look for a process or valve gain close to 1 %PV/%OUTPUT and as constant as possible. Valve dead band and resolution are key valve tracking performance parameters. Use the EnTech Control Valve Dynamic Specification V3.0 is aligned with the ANSI/ISA 75.25 standard and is a good guide to help specify control valve performance metrics around response times in the four regions.

Look for many of the earlier posts featuring James’ wealth of experience and expertise about valve and control loop performance. He summed up his presentation noting that many operational problems can be prevented, and process control significantly improved, by proper selection of the control valve. Consider control loop stability and performance when selecting a control valve and pay close attention to the valve gain, dead band, resolution and response time regions. You simply can’t fix severe control valve nonlinearities with PID loop tuning.

Visit the Control Performance Improvement & Optimization section on Emerson.com for more on ways to improve overall process performance. You can also connect and interact with other control performance experts in the Services group in the Emerson Exchange 365 community.