It’s encouraging to see the comeback in shale oil & gas production here in the U.S. Oil & gas producers have made great strides in lowering the costs of drilling, hydraulic fracturing & completion and ongoing well pad production. A recent CPI Financial article noted:

Shale oil output in the US may grow sequentially by 600 thousand b/d from 4Q16 to 4Q17 on increased activity in oil rigs and fast productivity gains. Importantly, breakeven costs for key major US plays now stand around the $55/bbl mark.

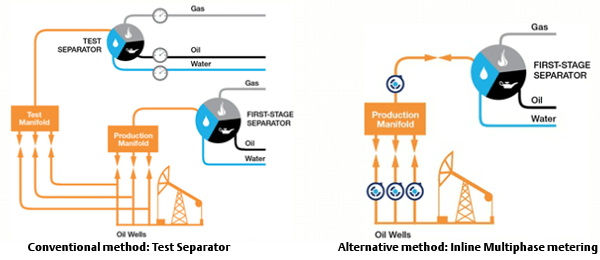

One way productivity gains are being made is in reducing the capital expenditures of the well pad processing equipment. Traditional methods using test separators and associated manifold piping and valves to measure oil, gas and produced water amounts per well are being redesigned with multiphase meters. Originally developed for offshore environments, the multiphase meter technology and modularity has advanced as a great option for onshore production applications.

In a one-hour recorded webinar, Advances in Multiphase Metering for Onshore Measurement in Oil & Gas, Emerson’s Laura Schafer described how this new and flexible multiphase measurement technology reduces the cost of multiphase allocation measurement and addresses a wide range of produced fluid compositions. Emerson’s Lars Anders Ruden and Martijn Tol joined Laura during the question & answer portion of the webinar.

Laura opened the presentation highlighting the measurement considerations oil & gas producers face in optimizing assets, producing safely and with process integrity, meeting regulatory requirement, and establishing accuracy in allocations and custody transfer transactions.

Laura opened the presentation highlighting the measurement considerations oil & gas producers face in optimizing assets, producing safely and with process integrity, meeting regulatory requirement, and establishing accuracy in allocations and custody transfer transactions.

Asset optimization includes reservoir and well optimization and process optimization to address optimum production levels and produced water constraints. Traditional flow measurement technologies do not handle multiple phases in the flow stream effectively. Some flow measurement technologies such as liquid turbine meters can be damage by bubbles caused by gas coming out of liquid phase. Differential pressure measurement can handle these phases but not measure the amount of each of the phases.

Multiphase meters can eliminate the need for test separators that separate oil, gas and water for individual metering. The test separator requires a separate test manifold from the well heads in addition the manifold that connects the wells to the production separator.

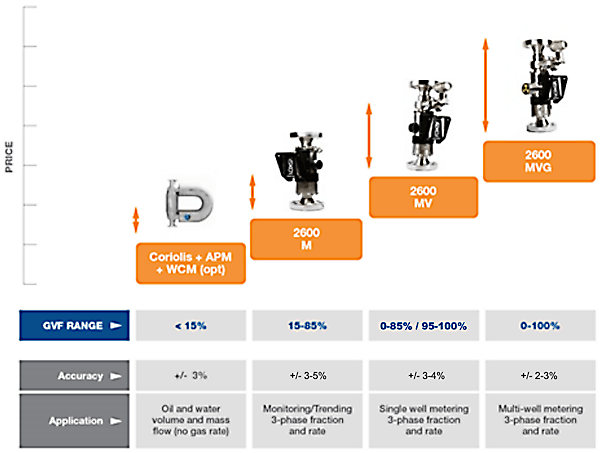

Given the wide range of flow regimes on well pad sites across many regions, Laura described a portfolio of products to address multiphase metering applications including the Micro Motion Elite meters with Advanced Phase Measurement (APM) and Roxar MPFM 2600 M, 2600 MG, 2600 MV and 2600 MVG. The MG option adds the gamma system (Cs-137 source + detector) to the meter, MV adds the venturi (designed as a field replaceable, insert sleeve) and increases the gas volume fraction (GVF) operating range.

The Roxar modular multiphase meters applies a combination of electrical impedance measurements and single high-energy gamma for determining phase fractions, combined with venturi and cross correlation for velocity measurements. These multiphase meters accurately characterize flow and provide a flexible solution for a range of applications, from measurement at the wellhead to complex well testing.

She described each of the technologies and how they work in more detail as well as their suitability in different flow regimes. Here’s a table that summarizes their applicability:

Laura summarized her the presentation by highlighting the flexible and cost-effective metering options suitable for oil and wetgas wells, direct wellhead monitoring, multi-well testing, allocation and fiscal metering, as well as shale well flow back monitoring.

Watch the full webinar for Laura’s presentation and Lars Anders & Martijn participation in the question & answer portion of the webinar, which begins at 45:50.

You can also connect and interact with other flow measurement and oil & gas industry experts in the Flow and Oil & Gas groups in the Emerson Exchange 365 community.