Monitoring the composition of what’s in an air mixture is important for many processes. Reasons may include detecting dangerous gasses for the safety of the plant personnel, getting the air-fuel ratio right for optimum combustion, or better understanding the mix of hydrocarbons in a gas stream to name a few.

At next week’s Emerson Exchange conference, Emerson’s Kyle Stewart is participating in a number of sessions sharing his expertise on applying gas analyzers. Here is a look at them.

Measure and Analyze Application Best Practices and Common Mistakes

Learn about best practices in specifying, installing, operating, and maintaining Rosemount Pressure, Temperature, and Analytical instrumentation. Talk to the panel of experts about your application and instrumentation questions. Learn about the most common installation mistakes that Rosemount engineers see from the field. Get a glimpse at new Rosemount technologies and how they can further address instrumentation challenges.

Solving Challenging Combustion Oxygen Measurements in Harsh Kiln Applications

Imerys Minerals processes diatomite using multiple rotary kilns averaging 35,000 cubic feet each. An oxygen analysis system was installed to ensure process efficiency and allow real-time adjustments to critical inputs for controlling product quality. A combination of a zirconia oxygen probe and insulating jacket allowed reliable measurements in harsh kiln conditions which include temperature up to 2100°F and high levels of dust and particulate. This critical oxygen measurement allowed Imerys to control the grade and quality of several million dollars of product each year.

Aceitera General Deheza (AGD) has a strong commitment with environment and local communities. As a part of their emission reduction program they are replacing fossil fuels by biomass and this change leads to a new variable to care about: particulate matter emission to the atmosphere. Emerson designed a solution combining the Rosemount OPM 3000 Opacity Monitor as a downstream complement of baghouse filters. Continuous measurements provide real time data. This information is then used by the process manager office to adjust the process and make decisions in order to reduce pollutants emission.

Some other interesting presentations related to gas analyzers include Automation and Continuous Monitoring of Silica in Peaking Power Plants, Fixed Gas & Flame Detection Best Practices, and Remote Diagnostics Support—Providing Expertise to Isolated Outback Australia

Some other interesting presentations related to gas analyzers include Automation and Continuous Monitoring of Silica in Peaking Power Plants, Fixed Gas & Flame Detection Best Practices, and Remote Diagnostics Support—Providing Expertise to Isolated Outback Australia

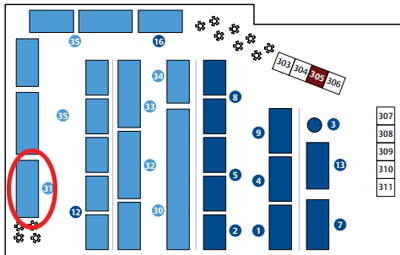

In the Technology Exhibits area, you can see some new and updated technologies in quantum cascade laser analyzers, wireless gas monitors and in-situ combustion analyzers. Here is the complete map of the Technology Exhibits on display at the conference.

You can also connect and interact with other analyzer experts in the Analytical group in the Emerson Exchange 365 community.