For production processes with flammable substances, flame arrestors are important safety devices that allow gases to pass through but prevent flames in order to prevent a larger fire or explosion.

A recent Control Engineering Europe article, Detonation arrestors reduce complexity and increase safety, highlights considerations in detonation arrestors, which are flame arrestors designed to prevent the transmission of a detonation in a confined system. These confined systems include piping systems that are manifolded or have long run-up distances (maximum attached pipe lengths).

The EN ISO 16852 standard, Flame arresters — Performance requirements, test methods and limits for use specifies:

…the requirements for flame arresters that prevent flame transmission when explosive gas-air or vapour-air mixtures are present. It establishes uniform principles for the classification, basic construction and information for use, including the marking of flame arresters, and specifies test methods to verify the safety requirements and determine safe limits of use.

The article’s author notes that, according to this standard:

Arrestors designed only for stable detonations require up to two additional independent measures of protection…

This requirement is because:

…stable-only detonation arrestors alone do not provide adequate protection against the most severe detonation events.

Flames in these confined systems:

Flames in these confined systems:

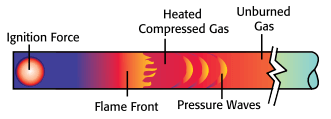

…normally start as a slow deflagration, a flame front moving at subsonic velocity and if the system allows, will accelerate to a detonation via a phenomenon known as ‘Deflagration-to-Detonation Transformation’ (DDT). DDT will occur when the highly pressurised vapours ahead of the flame front come in contact with the flame.

Upon this event, an:

…explosion occurs and the pressure wave ahead of the flame front becomes a shock wave. This shock wave produces tremendous compression of the gases both upstream and downstream from the initial point of DDT. A detonation is a flame driven shockwave at or above the speed of sound in the unreacted medium as measured at the flame front. As the flame propagates farther down the pipe, it goes into a dynamic state known as an unstable or overdriven detonation.

Highly localized pressure can result from the flame propagation traveling at supersonic and hypersonic velocities. Bends, elbow, tees, and final control elements such as check valves can induce additional turbulence.

Detonation arrestors are designed and tested for these unstable detonations and should be used in applications that have multiple turbulence inducing devices. It is:…not possible to predict where DDT might occur within the piping system. Therefore, it is not appropriate to use detonation arrestors that have been tested only for stable detonations, since they are not able to effectively stop detonations that might occur at or between the DDT and the point at which the detonation becomes stable. If conditions are right, a galloping detonation can occur.

Using:

…detonation arrestors designed and certified for both stable and unstable detonations protect against the most severe detonation events without requiring any utilities, control devices or operator intervention.

You can learn more about flame and detonation arrestors in a whitepaper, ENARDO Flame Arrestor Technology. You can also connect and interact with other pressure regulator and flame arrestor experts in the Regulators group in the Emerson Exchange 365 community.