Douglas Morris

Power and Mining Industries Sr. Manager

Automation and control in mining can be difficult on a number of fronts. The first being constantly changing ore which varies in grade and hardness and causes different parts of the processing plant to become limiting to operations. A second automation problem is very application specific and is related to the measurement of slurries.

Slurries loops are found downstream in the concentration process and pose difficulty because they are highly erosive and often corrosive. Magnetic flowmeters are commonly used in these applications and can be damaged within days or weeks if they are not selected properly. In addition, some meters in this service can give erratic measurements due to high solid content.

Proper selection of inline materials is the key to dealing with erosion and corrosion. One must consider the liner which needs to be matched to the slurry. This will improve life of operations as will the use of lining protectors and matched internal pipe diameters. Flush mounted electrodes should be considered when solids are larger in size. Electrode materials that are much harder than standard are also available and can provide increased life with reduced noise profile. Good engineering practices will provide excellent life for these flowtubes.

Dealing with noisy signals can be more problematic, though, particularly when a loop requires a signal representative of the process. The common approach for is to increase damping, but this artificially creates a stable signal and can mask real process changes which can lead to increased loop variability. A better approach is to use unique noise mitigating technologies.

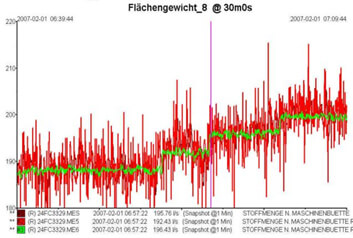

Emerson employs a number of mitigation solutions to improve signal to noise ratios, including software that detects process noise and automatically reports the signal-to-noise ratio at multiple coil drive frequencies to allow the user to achieve better signal stability. This works great for slurries up to about 50% solids content. Following is a graph of a typical magmeter (red) and an Emerson high frequency meter (green) in a slurry application.

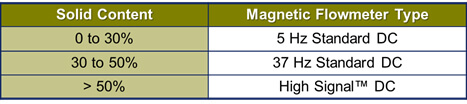

Increasing frequency works great, but what about applications like dewatering where you are trying to maximize the slurry content? This is where a unique approach is required…it’s called a high signal magmeter. By applying ten times the current to the flowtube, an extremely high signal to noise ratio can be achieved to provide stability even in the most difficult applications. The following recommendations are for mining slurries:

By employing the right magmeter technology, a miner will be able to accurately measure slurries and tighten the control in these important loops. This is particularly relevant as mines are focusing on productivity improvements like increasing recovery and reducing water usage.