Emerson’s Chris Womack discusses process control with IEC 62591 wireless devices in today’s guest post.

Using wireless devices in process control still isn’t that common, but it’s going to be. With its quick and easy installation, wireless technology is often used for providing additional measurement data that’s not essential to control. But the flexibility of wireless is increasingly suited to permanent, closed-loop control schemes too.

Using wireless devices in process control still isn’t that common, but it’s going to be. With its quick and easy installation, wireless technology is often used for providing additional measurement data that’s not essential to control. But the flexibility of wireless is increasingly suited to permanent, closed-loop control schemes too.

That’s because there’s been a lot of progress dealing with two main worries that keep manufacturers from trying wireless in anything but an open-loop capacity.

The first is a concern that wireless communication will be too intermittent—especially when intensified by electromagnetic or physical factors—leading to inappropriate controller responses. For example, causing a controller to overshoot or undershoot the set point by omitting key measurements of a changing process variable.

The other worry is more about logistics and safety. When wireless devices are in constant wi-fi contact, they need their batteries changed fairly often. And that would pile on yet another task—one that exposes personnel to the potentially hazardous conditions of the field.

So what’s there to do about these challenges? I recently had the chance to work with Emerson process control expert James Beall on a white paper that addresses both. It’s simply titled “Control with Wireless” (pdf) and it’s best to read the whole thing, of course.

But here are a few choice excerpts to show you where it’s going. So first, how is it done? [hyperlink added]

Configuring wireless devices to transmit updates less frequently can greatly increase battery life—sometimes by years. And unlike traditional PID, [the Emerson DeltaV digital automation system‘s] PIDPlus includes modified integral and derivative portions that can accommodate signal interruptions and update-rate variations, including the variations that battery-saving transmission schemes can introduce.

Leave aside for a moment the whole PIDPlus control algorithm. How do you get useful measurements of a changing process variable when you reduce the overall transmission rate? [hyperlink added]

Some signal transmission schemes, such as the “report-by-exception” scheme available with some Hart 7-compliant devices, have been able to reduce communications-related power usage by more than 90 percent in certain situations.

…

For example, energy efficient wireless devices can continue to make measurements at regular intervals, but then only transmit an update to the controller under two conditions: when a measurement deviates from the previously transmitted value by a certain amount, or when a predefined period of time has elapsed since the last transmission.

Besides, traditional wired devices usually oversample process variables, sending measurements four to ten times more often than the controller executes its control algorithm. And they send a lot of measurement data that’s nearly identical to information in preceding signals.

On to PIDPlus. Traditional PID isn’t built to handle measurement data that arrives in spurts …

… it executes at a regular, periodic rate, and it requires a new measurement value when it performs each execution. These factors affect how the algorithm’s integral and derivative portions respond to variations in the rate at which it receives measurement updates.

But modified terms in the integral and derivative portions of the PIDPlus algorithm allow it to accommodate measurement-update variations. The integral portion of PIDPlus updates only when the controller receives new measurements, and the derivative portion includes a term that incorporates the time elapsed since the most recent measurement.

The paper goes into some detail about why and how traditional PID responds inappropriately when it gets measurement signals at a variable rate. It also takes a technical look at how PIDPlus works differently, allowing it to sidestep some problems that other algorithms can run into. It’s a bit involved for a blog post, but here’s how the PIDPlus’s integral component is different:

As long as PIDPlus is receiving new measurement updates, its integral portion … incorporate[es] the previous controller output to calculate its contribution to the current output. But when PIDPlus does not receive a measurement update to use in an execution, its integral portion does not change its contribution. Instead, it contributes the value associated with the most recent measurement update.

For example, if PIDPlus receives a new update prior to one execution, but does not receive an update for the next three, the modified filter will contribute the same value to all four algorithm executions.

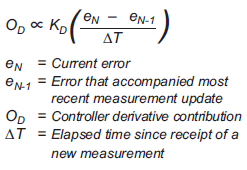

The algorithm’s derivative component is also modified—specifically, it doesn’t rely on a constant “time-elapsed” term, which is what traditional PID does. Instead it uses a variable “time elapsed since most recent measurement update” term. Here’s what it looks like in figures.

And as a result, it doesn’t overcorrect when a period of communications silence is followed by a measurement update.

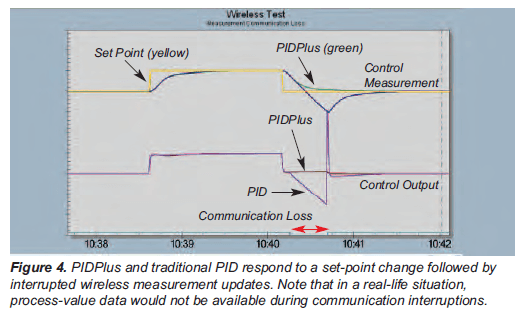

In field tests, PIDPlus behaved very well. In the paper, you’ll find the results of two such trials—here’s the figure that accompanies one of them.

So it looks like that far-off day may already be here—it’s possible to both save battery power and make good use of measurement-device updates that arrive at a variable rate. Here’s James Beall’s paper again, with the last word on combining PIDPlus with “report-by-exception”:

This arrangement sacrifices very little control performance when a fast measurement rate is coupled with a signal-transmission rate that increases when the process changes significantly. PIDPlus’s enhancements complement this scheme, using modified integral and derivative terms that account for the actual wireless measurement update rate.