Emerson’s David Newman, a member of the Oil & Gas industry team, had an Emerson Exchange presentation, Onshore Wellhead Automation – “I need a better return for my Wellhead Operation”.

He opened by highlighting the imperative of oil & gas producers to achieve “first oil and gas”, that is, get the new production wells online as soon as possible to begin to recover the capital costs associated with exploration, drilling, production equipment, and labor. He asked, “Is getting to first oil and gas time consuming and losing you production?”

Other questions he raised included:

- Are trips to the field and compliance requirements causing you problems?

- Is not having actionable data keeping you from optimizing production and yield?

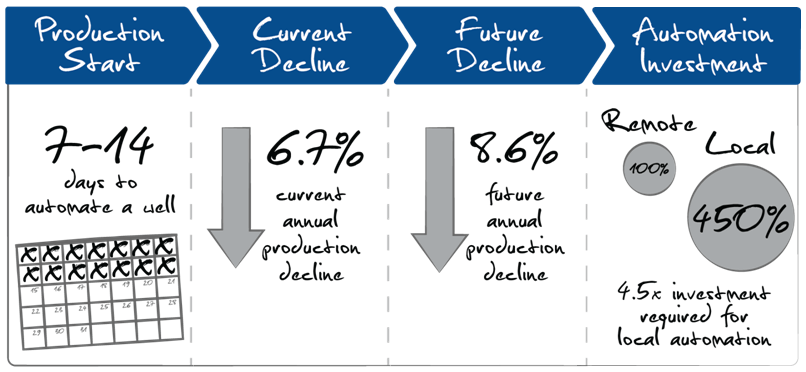

He noted that the following numbers tell a story about the challenges oil and gas producers are facing when it comes to their operations. 7-14 are number of days, according to oil and gas producers surveyed by the team, that it takes them to automate a well once drilling is complete. 6.7% is the percentage annual decline in well production today. 8.6% is the annual well production decline expected by 2030. And finally, 4.5 is the number of times most operators will re-invest their initial automation cost over the life of the well.

He noted that the following numbers tell a story about the challenges oil and gas producers are facing when it comes to their operations. 7-14 are number of days, according to oil and gas producers surveyed by the team, that it takes them to automate a well once drilling is complete. 6.7% is the percentage annual decline in well production today. 8.6% is the annual well production decline expected by 2030. And finally, 4.5 is the number of times most operators will re-invest their initial automation cost over the life of the well.

David shared how these numbers play out for oil & gas producers, and what the impact is on their operations. Better information is at the heart of operational improvements. Integrating wellhead automation can be time consuming, require a high level of skill and resources, which are scarce in today’s high-price oil era. Also, trips to the field are expensive, increase safety risk and add to overall compliance costs. Finally, without this information, you have insufficient ability to control and optimize a well’s production, to centrally analyze data to optimize production, and to monitor and enhance your field production strategy.

He highlighted some ways technology and expertise can be brought to bear. As we highlighted in an earlier post, Wireless Annular Pressure Measurement on Offshore Oil and Gas Wells, additional wellhead instrumentation improves well integrity by spotting problems earlier and mitigating their effects more quickly. This additional instrumentation and connection with wellhead control strategies can optimize production, improve injection well efficiency, improve tank management, and reduce personnel exposure to health and safety risks.

David shared results from projects where these technologies have been applied with this additional measurement and control. Oil and gas producers have seen overall production increases of 10%, operating cost reductions of 25%, and first oil and gas schedule reductions numbered in days.