I caught up last week with Emerson’s Al Novak. You may recall Al from some of our alternative fuels-related posts. He mentioned that they had another Alternative Fuels and Energy Summit in Cambridge, Massachusetts. The focus of this summit was on using “biomass” feed stocks and using biochemical, thermochemical, or combustion technologies to convert the feedstocks into to fuel and energy. Nearly 50 people attended this event.

For those not familiar with the term biomass, I turn to Wikipedia, which defines it:

…a renewable energy source, is biological material derived from living, or recently living organisms, such as wood, waste, and alcohol fuels. Biomass is commonly plant matter grown to generate electricity or produce heat.

One of the presentations given was Biomass Energy Optimization by Emerson’s Chip Rennie. I’ll highlight some of the points he shared with the summit attendees. On the value in burning biomass, Chip noted that waste fuel substitution could reduce costs of manufacturing more than any other single change.

From a capacity standpoint, biomass power represents the largest source of renewable energy, surpassing hydro-based energy production. Biomass power plants divert wood waste from landfills, which reduces the production and atmospheric release of methane. According to the U.S. Environmental Protection Agency (EPA):

Methane is over 20 times more effective in trapping heat in the atmosphere than carbon dioxide (CO2) over a 100-year period…

Chip’s final point on burning biomass is that it can result in zero net carbon dioxide emissions because any carbon dioxide released by burning biomass can be removed from the atmosphere by growing more biomass.

Chip shared some U.S. biomass statistics. In 2008, biomass accounted for about 1.4% of total U.S. power generation nearly equaling wind, solar, and geothermal power production combined. The use of biomass as a fuel source is expected to grow tenfold between 2008 and 2020.

Some of the challenges for process manufacturers and energy producers using biomass fuel are inconsistent calorie, moisture, and sludge content, difficulty in handling (feeder plugging, conveyor trips, etc.) and inconsistent material size. These challenges are offset by biomass fuel advantages in high caloric value, abundant supply, lower emissions, relative lower costs, and reduced carbon footprint compared with traditional fuel sources.

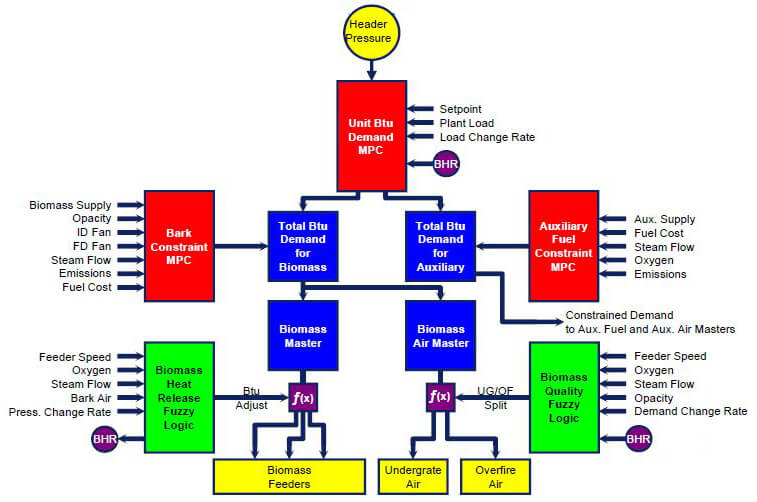

Chip shared some process control and optimization strategies for biomass multi-fuel boilers. These strategies involve the use of model predictive controllers with systems such as the DeltaV automation system for the unit BTU demand, bark constraint, and auxiliary fuel constraint. In addition, fuzzy logic blocks are used to calculate biomass heat release and biomass quality.

Biomass heat release is calculated from feeder speed, oxygen, steam flow, bark air, and pressure change rate. Biomass quality is calculated from feeder speed, oxygen, steam flow, opacity, and demand change rate. These algorithms help adjust the controls to the changing conditions of the biomass.

While the use of biomass as a fuel continue to grow, the summit attendees echoed that feedstock and legislative policy continue to be the major hurdle in successful projects. Emerson’s James Stanley who also attended this summit relayed a quote from Dr. Tom Amidon from State University of New York College of Environmental Science and Forestry (ESF). He stated:

Feedstock is the tail that will wag your dog.