Inside the Emerson firewall, we have a growing community of bloggers who share their expertise with other Emerson folks and local business partners. Hopefully more of these voices will emerge over time, sharing their expertise externally with the world.

I saw a post this week from the Rosemount team about installation best practices in the power industry. Power Industry leader, Rajesh Nogaja lead the effort to show how Rosemount products could be used to improve the power generation process.

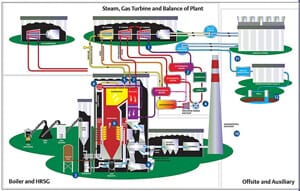

On the external EmersonProcess.com website, the team created a graphical interactive application, Proven Installation Practices in Power Applications, to show these opportunities.

For instance, if you click on the steam and gas turbine area of the graphic, the application takes you to a closer view of the steam, gas turbine, and balance of the plant graphic.

For instance, if you click on the steam and gas turbine area of the graphic, the application takes you to a closer view of the steam, gas turbine, and balance of the plant graphic.

Once you click on the graphic to activate it, the graphic becomes dynamic and shows what measurement can be added to improve the operation of this part of the plant. Marker one points to the saturated steam flow measurement. It displays the best practice, in this case, having accurate measurement helps accurately calculate thermal cycle efficiency for these turbines.

I asked Rajesh from his experience which measurements were most often overlooked and a source for energy efficiency improvement. Rajesh pointed to condensate level measurements in heaters, condensers and deaerators. Accurate level control can optimize thermal cycle efficiency and improve plant heat rate. Guided Wave radar, which is immune to high vibrations and density changes, improves the condensate level controls under heavy load fluctuations. This measurement accuracy is not possible with conventional DP level or displacer type technologies.

Another often-overlooked area in most of power plants is accurately measuring main steam flow and extraction steam flow. These measurements are generally inferred from turbine first stage pressure or condensate flow. The direct flow measurement enables online heat-mass balance and optimizes part load and full load thermal efficiencies in the plant.

If you’re responsible for optimizing a power plant and haven’t done so already, look at these proven installation practices. I invite your comments on your experiences with key measurements and their impact on efficiency.