Valves used in process safety applications remain static for much of their existence in a manufacturing or production process. Digital valve controllers can play an essential role in ensuring these valves operate as they should when called upon in an abnormal situation.

For safety valves used in throttling applications, digital valve controllers enable precise control through accurate valve positioning to avoid process instability, which can lead to unplanned shutdowns.

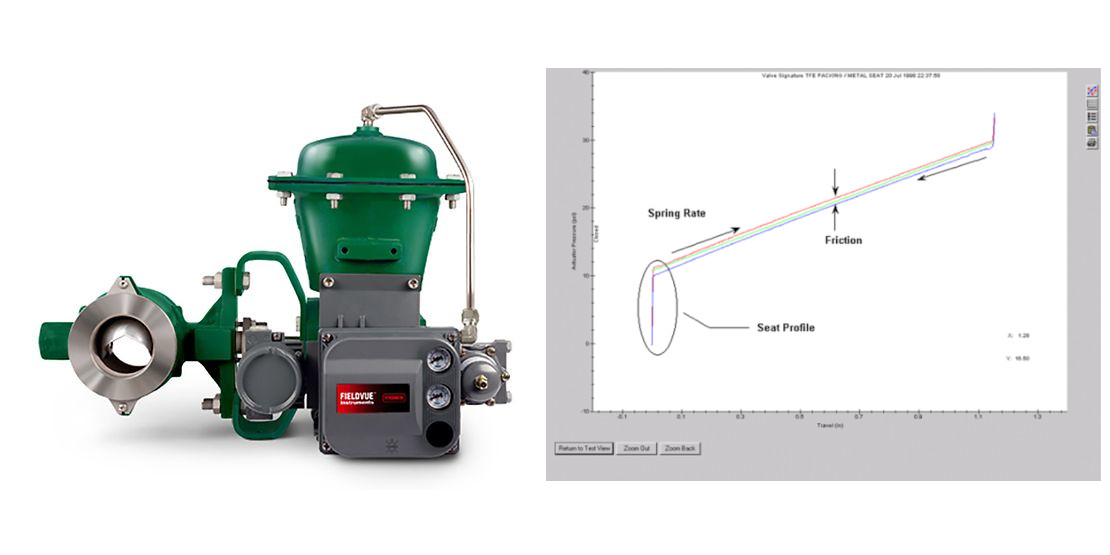

For open-close safety valves, digital valve controllers such as the Fisher FIELDVUE DVC6200 SIS digital valve controller can perform self-diagnostics to provide valve performance and health evaluation without shutting down the process. These diagnostics include partial stroke testing to perform slight movement on a valve to ensure it is not stuck and can perform on demand.

Other diagnostics include checking for stuck solenoids, low air supply or pressure droop, dirty air supply, and many other mechanical issues.

Fisher ValveLink software allows your maintenance and operations personnel to monitor control valve health and performance online to improve reliability by spotting problems before they affect your process. This software is used to configure, calibrate, and diagnose FIELDVUE instrumentation.

Fisher ValveLink software allows your maintenance and operations personnel to monitor control valve health and performance online to improve reliability by spotting problems before they affect your process. This software is used to configure, calibrate, and diagnose FIELDVUE instrumentation.

By analyzing this data over time, predictive maintenance practices can be established to flag potential failure conditions and proactively repair them to avoid unplanned incidents.

The data collected by digital valve controllers can be used for compliance support. Collected data can be used for audits to ensure adherence to safety integrity levels (SIL) and to prove that the safety valve is sufficient for the safety instrumented function in which it operates. It provides a time and date stamp on all tests and reports, which is very important for complying with the requirements of statutory authorities.

Emerson’s Riyaz Ali highlighted additional benefits in a Processing magazine article, How Digital Valve Positioners Can Simplify Safety Life Cycle Phases.

These include eliminating expensive pneumatic test panels, reducing manpower requirements, lowering base equipment cost, and shortening testing time. In addition, remote testing results in fewer maintenance trips to the field, as well as the establishment of an automated test routine.

Digital valve controllers enable manufacturers and producers to improve overall safety practices and reliability. Visit the FIELDVUE DVC6200 SIS Digital Valve Controller and Valve Reliability Suite Solutions sections on Emerson.com for solutions to help you drive operational performance improvements.