Emerson’s Jonas Berge recently posted to his LinkedIn feed about the four types of Industrial AI—and how to use them correctly. I wanted to capture it here on the blog for posterity.

I spoke on the “The four types of industrial AI and how to use them correctly” at the #TNChE conference. I explained how to use the various forms of AI part of advanced plant automation with example use-cases from plants along the chemical industry value chain from refining and petrochemicals to bulk chemicals and speciality chemicals supporting plant personnel in production operations, sustainability, and maintenance. I also covered how AI supports plant automation modernization projects.

I started with a tutorial on machine learning (ML), deep learning (DL), causal AI, and GenAI because AI is misunderstood by many due to all the hype going around. Causal AI meaning based on first principles (1P) physics and chemistry as well as well-known cause and effect (C&E).

The examples showed where to use each of ML, DL, causal AI, or GenAI for the best results:

💧Production Solutions

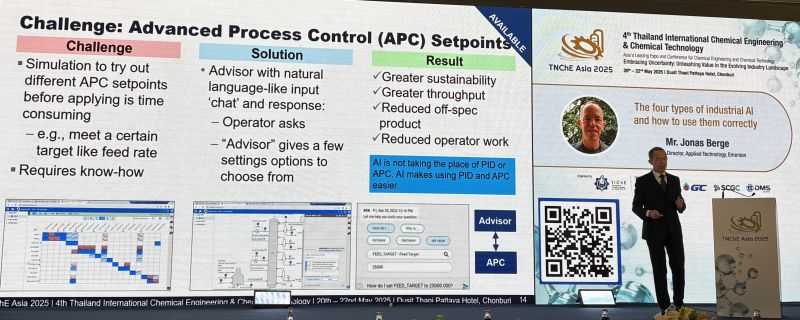

• Optimum advanced process control (APC) setpoints: 1P, DL, and co-pilot

• Interpreting planning and scheduling results: 1P, ML, and co-pilot

• Multi-unit dynamic optimization: ML & 1P🔧Reliability Solutions

• Equipment failure: Causal (C&E)

• Loss of containment due to corrosion / Erosion: Causal (1P)

• Control valve failure and underperformance: Causal (C&E)

• Process induced asset failures: ML & 1P🍃Sustainability Solutions

• Equipment fouling: Causal (1P)

• Venting and flaring: Causal (C&E)

• Steam loss: Causal (C&E)⚙System Engineering Solutions

• Control system configuration database migration: Rule-based, ML, and GenAIWe also demoed these solutions in our booth in the associated exhibition.

You can follow Jonas’ writings on LinkedIn by connecting, following, or visiting his Recent Activity page.

Update: Jonas added a LinkedIn comment which I’d also like to memorialize here on the blog.

AI is a toolbox. Engineers now must learn for which job to use which software tool with which #industrialAI technology: #causalAI, #MachineLearning, #DeepLearning, or #GenAI – just like engineers must know when to use a screwdriver, hammer, spanner, or rivet gun. None of them is best for every job.

In plants, we need #AI that we can trust; based on cause & effect knowledge of subject matter experts: first principles physics and chemistry, and well-known failure mode and effect analysis #FMEA so we can explain why we got the result we got – this builds confidence in using the advice from the AI. AI that give the same output for the same input every time. Deterministic. Therefore, causal AI is the most important tool for plants.

GenAI like LLM will be used as user interface providing a natural language interface to underlying causal AI.

Lastly, AI without sensors is like a brain without senses. There is no effective AI without complete real-time data. Automating manual data collection (portable testers and reading gauges) with sensors is the foundation on which AI rests.