Posts that describe advanced measurement technologies are pretty popular with our readers. That’s why I wanted to highlight a recent press release, Emerson’s New Fixed Point Gas Detector Provides Fast and Reliable Detection without False Alarms.

This fixed gas detector uses advanced optical absorption detection technology to provide reliable and fast gas detection in all plant environments. It offers fast and reliable detection of hydrocarbon gases without false alarms. It’s essential that these gas detectors be able to operate reliably in hazardous environments, in ducts, and all-weather conditions.

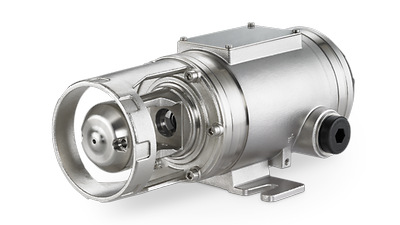

The Rosemount 625IR Fixed Gas Detector transmits infrared light through a sapphire lens. When a gas cloud moves through the detector, the target gas wavelengths absorb some light wavelengths, reducing their energy. The light is reflected back into the detector, where the infrared light sensors measure what wavelengths and how much infrared light has been received to determine the gas concentration.

These fixed gas detectors can be placed in areas with potential leak points. As a gas cloud needs to come into contact with the gas sensor to signal a warning, and since ambient air movement affects where a gas cloud may drift, it’s recommended to locate multiple gas detectors across the facility.

The Rosemount 625IR Fixed Gas Detector is certified to SIL2, SIL3, ATEX, US and IECEx safety standards. It can operate in an ambient temperature range from -40 to 167degF (-40 to 75degC). An upcoming release will have an arctic configuration option in which the ambient temperature range will be -76 to 149degF (-60 to 65degC).

Visit the Fixed Gas Detectors section on Emerson.com to learn more about these devices used to detect gas leaks and inadvertent releases of combustible and toxic gases.