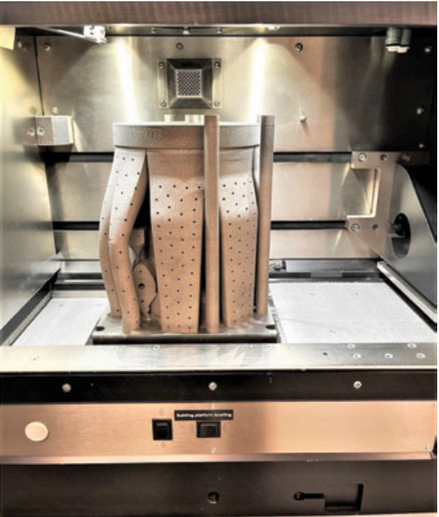

This prototype valve body was printed with hollow breakaway supports for development testing. Metal additive manufacturing allows for shorter lead times and quicker iterations during development, as compared to traditional fabrication methods. This facilitates faster overall development times and allows engineers to explore non-traditional designs.

One form of AM, laser bed powder fusion (LBPF), has opened pathways to produce actuators, regulators, valves, and related parts that are optimized for chemical processing applications, but there are some challenges in making their production as quick and economical as possible.

My article in the March 2024 issue of Chemical Engineering, titled “Improving the Additive Manufacturing of Parts for Chemical Manufacturers,” discusses these challenges and shows how they can addressed by optimizing LBPF parameters.

Challenges in LBPF manufacturing

Because LBPF inherently produces a rough-surface finish, any parts that require tight tolerances, such as threads and bores, require additional machining.

As a result, there have been various attempts to try to shorten the overall manufacturing process of the finished part, either by the creation of hybrid AM systems with built-in computer numerical control capabilities, or by improving the properties of the material itself to make it more amenable to machining.

In many cases, adjusting the LBPF processing parameters is the preferred approach. Specifically, reducing the height of each powder layer decreases surface roughness, but at the cost of increased build time. Because changing layer height affects the structural properties of the finished product, other parameters, such as the laser scanning speed, may need to be modified to ensure that these reduced-roughness builds maintain mechanical integrity.

An investigation into LBPF parameters

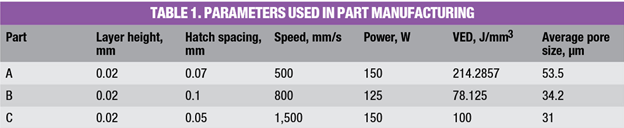

To determine suitable combinations of LBPF parameters, three tensile bars were produced using different parameter values, and they were then evaluated using tensile tests, hardness tests, and microstructural analysis.

The experiment sought to evaluate the predominant effects of varying laser scanning speed, laser spot size, layer thickness, scan patterns, and laser power. Because each of these parameters can influence the material microstructure, it is important to test for defects.

For example, balling effects occur when melted powder forms into beads, preventing smooth layer deposition and decreasing the density of the resulting build. In the three bars tested, the laser power and scan speed were suitable to prevent balling. Pores are another common defect and were observed in each of the bars to varying degrees, with high laser power and low scan speeds causing the greatest porosity.

Metallography revealed deformation twinning in each bar, which is believed to have been responsible for elevated plasticity observed in the samples. Tensile testing showed that the build with the fastest print speed had the greatest ductility.

Summary of findings

Layer thickness, hatch spacing, scan speed, and laser power clearly affected the internal structure, including porosity, and the development of cracks where fusion did not occur between layers. A high scanning speed with a hatch distance of 0.05mm was found to be best for minimizing porosity. The various samples did not show significant differences in yield strength and ultimate tensile strength.

AM has already provided many benefits to chemical manufacturers, and going forward, optimizing LBPF processing will further increase performance, lower prices, and shorten delivery times for valves and related components.