Since their introduction over a century ago, plastic products have become ubiquitous. Unfortunately, plastic waste degrades very slowly, and over time it breaks down into microplastics that harm the environment.

Some efforts to address this problem involve replacing plastics with biodegradable alternatives, while others seek to recycle plastics after use. However, recycling plastic is difficult compared to materials like steel or aluminum. Our article in the April 2024 issue of Chemical Engineering, titled “Control Valve Selection for Plastic-Recycling Applications,” details the process of recycling plastic via pyrolysis, and it shows how to address the valve challenges in this application.

Recycling options

Burning plastic waste is a simple way to keep it out of landfills, but the environmental costs of ongoing plastic production and incineration are high. Alternatives include:

- Mechanical recycling, which separates different types of plastics and remelts them to create new products.

- Dissolution, which uses solvents to melt specific plastics for reuse.

- Depolymerization, which uses chemical processes to break down long-chain plastic polymers into monomer building blocks.

- Pyrolysis, which breaks plastics down into oils, naphthas, light ends, and waxes under very high temperature and pressure.

The pyrolysis process

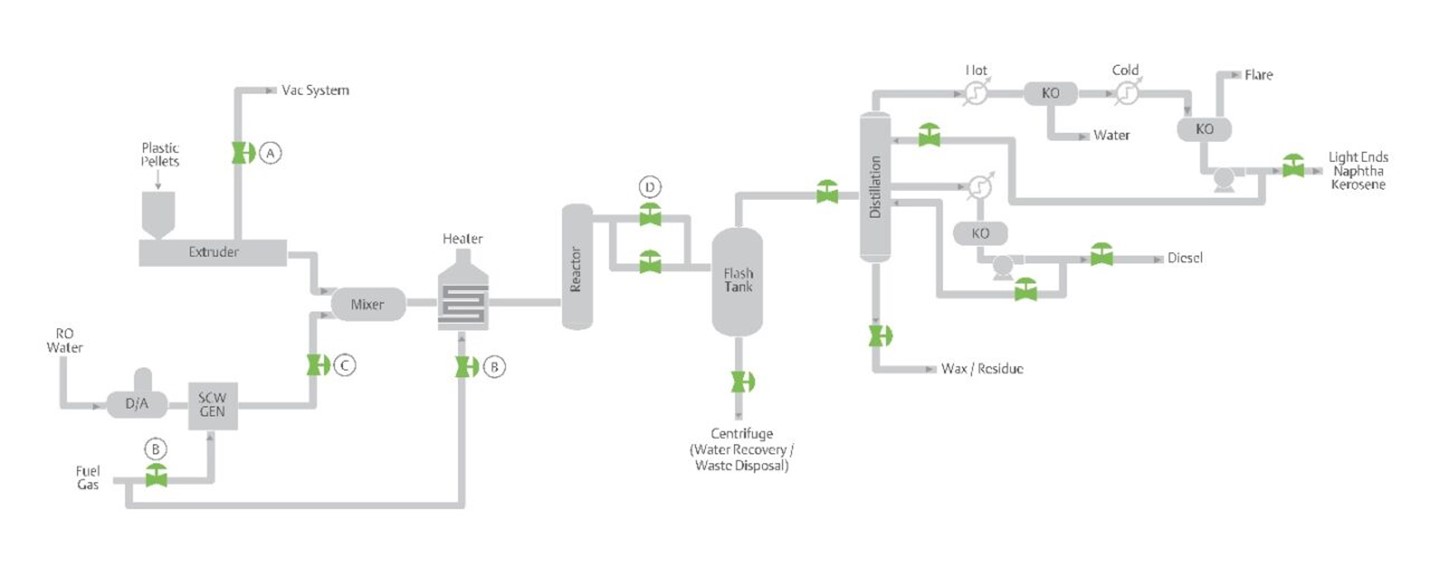

While individual pyrolysis processes may differ, most include the same fundamental chemical steps. Following infeed processing to remove non-plastic contaminants, the plastic is ground into small pieces and fed into an extruder, which melts the pieces and combines them into a homogenous mix.

Then, supercritical water is mixed with the extruder output, and a heater and reactor subject the mixture to high temperature and pressure, breaking down the mixture further. The mixture then passes through a pressure letdown valve and enters a flash vessel, where water and unreacted solids are separated from the superheated hydrocarbons.

Finally, the hydrocarbons are separated into diesel fuels, light ends/naphtha/kerosene, and waxes in a distillation vessel.

Control valve challenges

Many of the control valves used in the pyrolysis process are similar to those in petroleum refineries, and many of the valves used in the process require special consideration. For example:

- Valves associated with the extruder off-gas system may encounter corrosive chlorine gases, so the appropriate body and trim material selection are key.

- Valves controlling heater gas feeds should have high-quality positioners for tight control to maintain consistent heater temperatures.

- The valve controlling supercritical water flow to the mix chamber must be carefully sized and selected to handle intense temperatures and pressures, as well as potential pressure drops and thermal expansion problems.

Pressure letdown valves feeding the flash tank face the most challenging conditions of all.

These valves face an unforgiving process with high pressures and temperatures, extensive off-gassing, and a three-phase mixture of vapors, liquids and some unreacted solids, with the latter tending to plug ports. Very high pressure drops, velocities, erosion, and possibly chemical corrosion are likely.

Even with proper material selection, eventual damage under such conditions is inevitable, so ease of maintenance is paramount.

Finally, valves involved in the distillation process are like those in many refinery applications, but material compatibility issues may arise due to the diverse range of hydrocarbons involved.

Closing

While pyrolysis process design is still a work in progress, several large plants are already under construction or in early commissioning. Faced with such challenging applications, end users should consult with their automation provider for control valve selection guidance.