Energy costs, a significant portion of any industrial plant’s operating budget, present a promising opportunity for cost savings. As per the Energy Star Guide for Energy and Plant Managers, between 30% to 50% of an operating budget is typically allocated to energy. This implies that any enhancement in energy efficiency cannot only revolutionize your cost management but also bolster your corporate sustainability efforts, instilling a sense of optimism and hope.

At the ACHEMA 2024 conference, Emerson’s Michael Machuca delivered a compelling presentation on Measurement Strategies to Achieve Your Sustainability and Decarbonization Goals. He began by emphasizing the Chemicals industry’s pivotal role in advancing sustainability initiatives, particularly in four key areas: alternative feedstocks, process decarbonization, resource stewardship, and digital transformation. Notably, nearly 3000 chemical production companies worldwide have embraced net-zero targets.

Over half of the largest 500 companies have an internal carbon price for evaluating projects. 69% of the chemical industry’s most prominent players have carbon-neutral targets. To meet the 2030 targets, the chemical industry needs to drive a 12% improvement in Energy Intensity.

Within the chemical industry, fired heaters (furnaces & boilers) stand as significant energy consumers. These plant assets pose several challenges, including the need to meet increasing regulatory requirements to reduce carbon footprint, the delicate balance of excess air to ensure complete combustion without increasing emissions, the maintenance of efficient combustion despite variability in fuel quality, air supply, and analyzer measurements, and the necessity of skilled staff for manual control intervention. The control strategy’s impact on safety, efficiency, and environmental compliance is undeniable.

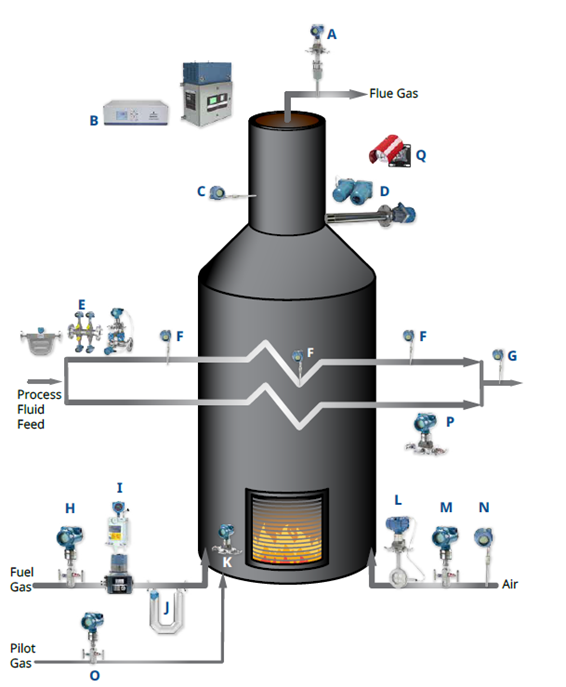

Accurate and reliable measurements around the fired heater. Some of Emerson’s fired heater solutions that can drive more optimized performance include:

Accurate and reliable measurements around the fired heater. Some of Emerson’s fired heater solutions that can drive more optimized performance include:

- Burner Management System (BMS) using Safety Instrumented System (SIS)

- Fuel flow and fuel BTU measurement

- Airflow measurement by direct instrument or pressure drop across the heater

- Air damper actuation and position measurement

- Excess oxygen measurement

- Emission Monitoring

- Optimized combustion control with fuel Btu compensation

- Flame stability detection

- Automatic start-up and shutdown routines

- Product charge and temperature optimization

- Asset monitoring functionality with predictive maintenance alerts

Micro Motion Coriolis meters can be used for mass-based fuel gas control to stabilize control and operate more efficiently. This tighter control reduces safety risks by stabilizing fired heater operation and avoiding trips during rich fuel conditions. Energy efficiency is increased, and NOx emissions are reduced by limiting excess air used in combustion.

The Rosemount 470XA and Rosemount 700XA gas chromatographs provide feed, fuel gas, and effluent composition to improve cracking severity without requiring costly shelters. Fast update rates enable tighter closed-loop control. Another way to improve overall combustion efficiency is to measure the oxygen and carbon dioxide in the stack with continuous and accurate monitoring of oxygen and the combustibles in flue gas using the Rosemount 6888 in-situ analyzer or the OCX8800 oxygen and combustibles analyzer.

The Rosemount 485/585 Annubar for larger line sizes and Rosemount Conditioning Orifice for smaller line sizes for accurate airflow measurement to improve air and flue gas measurements. These measurements help you increase energy efficiency and reduce NOx emissions by operating with less excess air and tightening airflow control.

Maintaining stable combustion is critical to the safe operation of fired heaters. When the ratio of airflow to fuel flow to a burner transitions from inside the burner’s operating envelope to outside the burner’s operating envelope, the combustion process becomes unstable and stops. The advanced diagnostics in the Rosemount 3051S pressure transmitter provide Statistical Process Monitoring (SPM) to monitor the draft measurement pulsations and detect the amplitude or frequency increase associated with flame instability. Avoiding a single shutdown can save a plant in the seven figures.

I’ll cover Michael’s section of the presentation on steam system optimization in a future post. Follow the links above for more ways to optimize your fired heater units’ energy and emissions performance.