In his presentation at the Emerson Exchange EMEA 2024 in Düsseldorf, Sven Girgensohn, E-EMC/OT E&I Engineering at BASF Personal Care & Nutrition GmbH, described how a modernized control system is supporting the need for greater flexibility and reliability of both new and existing production lines at its plant in Düsseldorf, Germany.

The Düsseldorf plant is BASF’s third-largest site in Europe.

The Düsseldorf plant is BASF’s third-largest site in Europe, at which it produces a range of ingredients for the cosmetics industry as well as renewable raw materials for household and industrial cleaners. The site hosts multiple semi-independent plants that utilize both batch and non-batch production with separate control systems. The plants have separate control systems including Emerson’s DeltaV™ distributed control system (DCS) as well as other older legacy DCS.

The modernization project aims to create state-of-the-art, flexible and reliable batch systems, but faced several significant challenges, not least balancing the need to migrate legacy systems to DeltaV systems while at the same time extending control systems for new production lines. There was also the need to perform system optimization, implement effective lifecycle maintenance, and ensure operational safety and effectiveness despite a growing system. There is also growing demand for inter-plant cooperation and coordination. The presentation outlined how these project challenges were met and some of the benefits being realized from adopting a modern batch structure.

The BASF site is following an integrated system extension and modernization approach, that incorporates the existing operating production lines, as well as new production lines. Minimizing downtime of the operating lines is a priority, which BASF is achieving with good preparation and skilled personnel. Typically, it can be challenging to find time to perform both system maintenance and changes, but BASF found that there are many non-disruptive opportunities to perform batch system updates, even during normal operation.

A classic software engineering-centered approach was deemed to be too tedious and rather slow. BASF has therefore adopted a very modern cooperative project approach, with earlier participation from all stakeholders and greater cooperation between the process, operations, maintenance and mechanical engineering teams. The benefits of this have included minimal downtime, reduced implementation time and improved system maintainability. In addition, forward-thinking engineering and better team building have brought process control, instrumentation engineering, chemists and operators together to form the basis for increased inter-plant coordination.

BASF determined that a good control system structure requires the use of class-based modules, “out of the box” equipment modules (EQM) and class-based procedure recipes that incorporate formulas and equipment trains. Emerson’s PCSD (PMO Configuration Standard DeltaV) software library helps to facilitate this, containing mostly class-based software for DeltaV, with software logics, batch configurations and graphics that provide field-proven, pre-tested, robust building blocks for DeltaV projects. These software are based on proven design standards, have been enhanced using previous experience and are fully documented. Critically, they can be merged with existing systems. Utilizing these tools is helping BASF to create a modern batch system that improves batch production efficiency, flexibility, safety and maintainability.

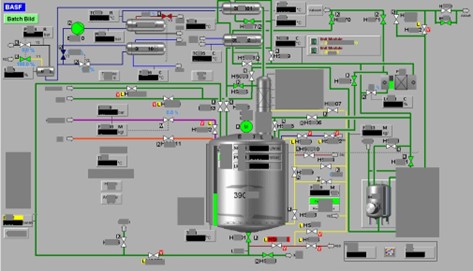

Classic, but outdated operator graphics

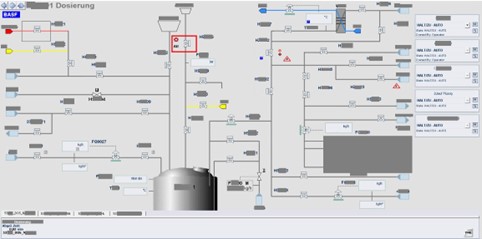

Improved HMI, utilizing human centered design provides clearer alarm indication

The modern control system also provides better operator support. An improved human machine interface (HMI) with human centered design graphics provides the basis for operational excellence. This frees up operators from performing basic tasks and supports them with more sophisticated value-adding tasks.

Contact your local sales office or Emerson Impact Partner for more information on how you can implement modernization projects. You can also connect and interact with other modernization and DeltaV experts in the Services group and DeltaV forum in the Emerson Exchange 365 community.