Original equipment manufacturers (OEMs) are important contributors to the manufacturing and production industries. Supporting their equipment through its lifecycle at their customers’ facilities is an essential part of their business success. Supervisory control and data acquisition (SCADA) systems can help them monitor the performance and provide services to keep the equipment operating in top shape.

Original equipment manufacturers (OEMs) are important contributors to the manufacturing and production industries. Supporting their equipment through its lifecycle at their customers’ facilities is an essential part of their business success. Supervisory control and data acquisition (SCADA) systems can help them monitor the performance and provide services to keep the equipment operating in top shape.

In this podcast, Evan Jubb joins me to discuss how the DeltaV SaaS SCADA system (formerly known and referred to as the Zedi SaaS SCADA system in this podcast) helps OEMs provide the level of service required to meet and exceed their customers’ expectations.

Give the podcast a listen and visit the DeltaV SaaS SCADA System page on Emerson.com for more on how it can help you improve your business performance.

Transcript

Jim: Hi everyone. This is Jim Cahill with another Emerson Automation Experts podcast. It’s often been said, do one thing and do it well. Many highly successful brands do this with their products. Think about Nike, totally focused around sports gear, Apple and their great tech products that many of us love and Uber focused around delivery people and food. For them, it’s all about easy, fast delivery as their product they bring to market. So, if you’re an original equipment manufacturer or OEM, it may seem like a no-brainer that in finding the right partners, you can totally focus on delivering your amazing end products that are the right fit for your business and deliver your end customers an exceptional experience.

And that’s what we’re gonna talk about today, how to get those quick, painless technology gains. As an OEM, I’d like to extend a warm welcome to Evan Jubb, who is Emerson’s Zedi global partner sales manager. But before we get too into the details or just how Emerson can help OEMs quickly and painlessly make these tech gains, Evan, can you tell us a bit about your current role and a bit about your background and experience? Oh, and I almost forgot, I was told you have an interesting background with dog sledding experience too. I’m not quite sure what that’s all about, but it certainly sounds interesting.

Evan: Oh yes, my dog sledding days that, that was fun. It’s great to chat with you, Jim. It’s an honor to be a part of one of your famous podcasts.

As for my background, I hold a bachelor’s degree from the University of Calgary in business. I joined Emerson back in 2016 in a business development role and have had several titles since. Corporate account manager, regional account manager, strategic account executive, and now my focus is on supporting local partners and helping them find solutions for their end customers as manager, global partner sales.

So throughout the years with Emerson, I’ve moved from Calgary to Pittsburgh, then to Houston, and now back in Calgary, Canada. As for the dog sledding, I lived for a winter in Canmore, Alberta and was a dog sledding guide, fuzzy hats, giant mitts, the whole deal. In truth, those dogs were the hardest working colleagues I ever had.

But you know, that job taught me important lessons. How vital it is to take care of your team, understanding their challenges, looking out for every member’s best interests, taking into consideration what may be holding them back. And you know how one lone link can really make or break an entire team that’s working towards something together.

So I find a lot of similarities with, helping our partners and OEMs find the best solutions. Understanding their biggest pain points and how we can help them overcome those obstacles and the struggles they face.

Jim: Well, that sure is a learning curve that most of us never get to experience, especially down here in Texas. I can really see how that would instill that determination in what you bring to people and the solutions, bringing those solutions together to overcome hurdles of any sort. So were you the guy driving the dog sled or did you have another role in helping care for the team of dogs?

Evan: It is all one role. The person that drives the sled is the same person that cares for the dog, making sure they’re healthy fit, giving them that encouragement that they need. And, you know, all the dogs kinda learn to trust each other as well as the driver. So they see me as a part of the team, maybe a leader on the team, but more is just another member that needs to pull his or her weight.

Jim: Well, that is really very cool or freezing cold as the case may be kind of an experience. I can certainly see now the connection and determination to care for help and overcome obstacles. And how that can translate into helping our OEM customers and partners. So, Evan, when you work with OEMs, what does that mean or look like from your angle?

Like who are those types of Emerson customers and what are some of the obstacles they face that you hear most often? And just throw another question in there. What do you do to help make it so painless to successfully adopt new technologies to help their business?

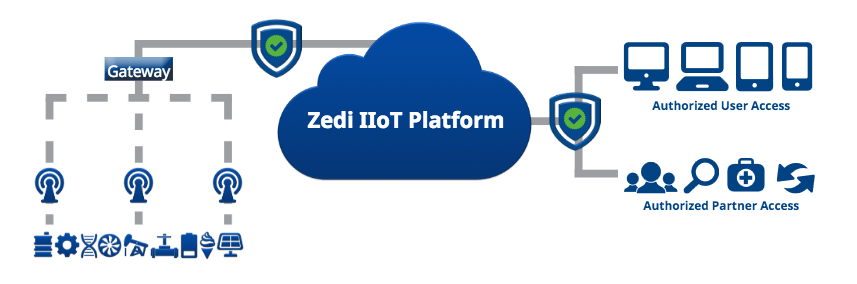

Evan: Well, I know for sure that defining exactly what an OEM looks like can certainly be casting a wide net and it’s a bit confusing. So for clarity, let me explain first up just a little bit about Zedi. The Zedi IIoT platform really boils down to connecting anything, so any device asset to anyone that is authorized to access this data. So that’s anytime, anywhere. And what that translates into is that we work with pretty much any industry and any OEM, we can get their remotely-located equipment or asset data to them in a format that makes sense, is easy to understand, flexible with their business needs and growth.

And always provide them the most up-to-date version of our software as a service. So as for who our OEM customers are, that’s a wide variety. Everything from sugar product producers, food and beverage producers, tank producers, suppliers, packaging producers, companies that treat hydrocarbons, I mean, the list goes on.

So we’ve really worked in lots of different industries, but one of the funner ones was we worked with a slushy drink producer and resellers to make sure that the slushy drink machines were always working on warm in summer days. So definitely a little bit different for us, but an exciting one. So certainly a wide array of products and services as part of an OEM customer offering.

The overall picture is that we are, of course, all industrial focused verticals. What instantly comes to, like many of the challenges to overcome could be the products safety and making sure that it’s effective.

Jim: Well, I guess there are tons of little kids and well, even some adult kids like myself out there in super hot summer regions that can be quickly disappointed if their favorite slushy flavor is outta stock or that machine isn’t working quite right. So that’s great to hear we’re helping out in those areas.

So how about some other more detailed examples of OEMs you work with that benefit from the production data Zedi delivers?

Evan: Oh, sure. Zedi is one particular OEM that’s a lubricant oil and fluid production company in the Northeast that has several end customers all across North America.

One of the largest customers producing a vast amount of steel made in the U.S. So that anywhere connection to their actual analytics about things like tank volumes, levels, temperatures, has been a game changer for them and their customers too. Today, they’re able to make sure their end customers have proof of the level of product used from the tanks for accurate invoicing, on-time ordering, scheduling, and now even the ability to shut off at set temperatures to increase safety for everyone.

They especially have great outcomes for enabling their end customers with the data they want and need. So while increasing internal communications from data and decreasing end customer stress with better scheduling, refills, and always just kind of knowing exact levels of products in their tanks.

So I really like that one. They’re a great customer to have. Another example of one of our OEMs is a packaging manufacturer, so they reached out to us when their business really started to take off a few years ago. Initially, they were having lots of difficulties trying to keep up with demand. They didn’t really have enough staff like most companies today. Couldn’t find the right skilled workers that they needed. But it was important for them to know certain set points of their production process.

They also want the flexibility to change what the data they were getting based on that process. So they wanted vibration data sets for one instance in their production. The next hour they wanted a wide range of whole different set of data for three different buildings over to get the right statistics on product delivery times and track scheduling correctly. It was our ability to be flexible that was significantly helping them overcome those challenges and even thrive with the added technology.

So there’s so many different types of OEMs that produce products everyone needs. But the one thing is that for sure, that no matter what you are producing or where you produce it, we can help you securely get the data you need to the right people at the right time.

Jim: Well, that’s a pretty wide range of customer examples, so it seems like Zedi isn’t really locked into just one segment or product type or even industry. That’s really fascinating.

Generally speaking though, what are the biggest obstacles you’ve helped with through the years for all those different types of OEMs? Is there any pattern to what their biggest challenges are, or is it really all over the board?

Evan: Yeah, Jim, there’s some very clear patterns and areas of obstacles that our OEMs are faced with on a regular basis. Mainly things they need help with are addressing improvements on actionable data that can help them make better business decisions.

So things like inventory tracking, product usage, mapping, producing downtime and increased safety for their products and their people, and ultimately their end users. So one thing that I think that usually stands out that most, the need of the data that presents actionable insights is that it needs to be easy to understand and really clear to the end users that are looking at it.

They don’t need a ton of data. They just need the right data for their role. So what’s relevant to their part of the business is what’s important and what’s gonna enable them to make decisions quicker, better, faster.

Jim: Yeah, that’s a really important point about the sea of data out there, getting the right data to the right person in order something actionable to be able to improve performance.

So in the bigger picture, they need technology like the Zedi IIoT platform to help them build greater efficiencies to help them increase their sustainability performance and profitability. Why do you think these are such big challenges for OEMs? Is it the difficulties in hiring supply chain or something else that they face?

I almost wonder if it’s the technology itself that can sometimes become a challenge to implement. I. If that’s not their core business or product focus to begin with. I think that all too often it’s easy for tech companies to assume a lot about their end customers and users that they can quickly forget the level of time planning and understanding that has to go into creating these types of efficiencies.

I know it can get pretty in-depth and for sure eat up a ton of internal resource time, just trying to make sense of it all. Much less actually getting things stood up and operating with the new technology to even begin with to help them. Would you say that’s fair or perhaps it’s a bit of a loaded question, but maybe you can shed some light on those types of difficulties OEMs often face.

Evan: No, Jim, you, you completely hit the nail on the head. It’s so true. Often the OEMs we work with not only vary in size, but they may lack internal resources, budgets, and abilities to really get new technology up and running. After all, it’s not their core business. Their core business is mostly about their end product quality and keeping their customers happy. In some cases, the service that comes with the product. But not only are they challenged with limited staff, they’re fearful to carve out the time internally to make these types of technology projects or changes and figure out how to implement them. So this is where finding the right partnership relationship is so important to OEMs.

Evan: No, Jim, you, you completely hit the nail on the head. It’s so true. Often the OEMs we work with not only vary in size, but they may lack internal resources, budgets, and abilities to really get new technology up and running. After all, it’s not their core business. Their core business is mostly about their end product quality and keeping their customers happy. In some cases, the service that comes with the product. But not only are they challenged with limited staff, they’re fearful to carve out the time internally to make these types of technology projects or changes and figure out how to implement them. So this is where finding the right partnership relationship is so important to OEMs.

The common denominator is usually based around making sure we know what we’re doing and we have the longevity to be there for them. There’s no worse experience than putting a ton of research and time into a project then six months later the partner turns out not to be committed. There happens when they don’t provide regular security updates. They aren’t willing to update their functions or offer support or training. Or offer training to new people or yes, you know, worse, they charge for things like support or update patches that aren’t even helping their business or their security.

We’ve worked with OEMs that are a bit shy because of these types of bad experiences Before. You know, the great news is for that search for your long-term, reliable, innovative company to partner with that will fully support your business growth and staff. It’s exactly what Emerson has to offer. The Zedi IIoT platform releases between 12 to 30 updates every year. Mainly security related, but also development for functions and abilities of customers and our customers and OEMs need and want to help increase their overall production, safety, & profitability. And probably most importantly, there’s sustainability.

So some of the other biggest challenges OEMs often face are like inventory control management, financial concerns across the board. You know, to get that strong ROI quickly is important to them. They need seamless workflows to help ease the stress of the staff that they’re lucky enough to have, and they want to enable those employees with fast decision making through analytics and actionable data to make their jobs easier while providing companies better results. That’s what we’re really hopeful to do. And of course, there’s tons of other challenges that they’re wanting to conquer and easily can.

Like scheduling, deliveries based of usage, internal communication to make sure everyone that needs to know something, knows it, and even the ability to provide proof to end customers of quality and usage as well. So communicating results to customers is key to them even being able to drive more repeatable business.

Jim: Yeah. There are so many important points you made there, that one about being with somebody that’s with you for the long haul. And it’s not all work done at once. It’s over the lifecycle that they need there, and then as getting into it, that analytics around what you need, what they need, what their customers need to do better.

So how does Emerson make these types of transitions through technology painless?

Evan: Yeah, we, we do our best to make it painless and to take advantage of the new technology ’cause we do offer all the things that OEM wants in a long-term partnership.

We have complete and ongoing training resources. Full twenty-four-seven live human support included. All while offering additional services like alarm management, machine health monitoring, and even project management. So, you know, getting things up and running quickly doesn’t need to absorb a bunch of internal resources that are already pretty stressed out with their roles.

Jim: Well, that sure sounds like every base is covered than to actually be painless and fast to start getting all that rich, actionable data quickly. So how does all this really impact successful outcomes from the OEM’s perspective?

Evan: No, I think one of the biggest game-changing outcomes is really built around the fact that each person on the staff gains access to knowing exactly what they need to know, no matter if it’s in the middle of the night or thousands of miles away from the production site.

They can get the exact data each person needs that is relevant to their role without all that other data they don’t need. So another big outcome, success is actually measurable by returns. So how much wasted product is now saved? How many more, fewer hours of people traveling to just check on machines and assets that are working just fine.

How many fewer people can get the same or more product created and sold? How much money is saved from machines and assets set on predictive maintenance schedules that also reduce downtime. There’s tons of ways to measure the successful outcomes of the set of Zedi IIoT platform and SaaS Suite provided.

But I seriously think the biggest one goes back to being trusted. Long-term sustainable partner they can count on that actually knows their stuff, can get them up and running quickly, and is there every step of the journey and hopefully create a more sustainable business model that can be passed along to the next generation of owners.

Jim: I think you’re right on target there, Evan. You’re right; when people have poured their heart and soul into building their products and their business, they do it to have a sustainable outcome for generations to come. I think they wanna see it continue to flourish far beyond their own lifetime and help the next generations of their families and friends and coworkers.

So, yeah. That in itself is a pretty huge outcome, if you ask me. Well, thanks again for joining me today, Evan. It was really great to hear how the Zedi IIoT platform and SaaS Suite deliver painless outcomes for OEMs who want to grow their business using technology as part of the mix. Great stuff. And thanks to all of you who have tuned in to listen to this podcast. We look forward to chatting with you again in the future.

Evan: Thanks for having me on, Jim. Really appreciate it.

-End of transcript-