Emerson’s Melanie Novacek presented Ovation Advanced Process Control Pump Performance Algorithm at the 2023 Ovation Users Group Conference. Melanie opened by highlighting the APC Toolkit Pump Performance Algorithm in Ovation 3.8 systems and later.

APC Toolkit pump performance algorithm calculates the following for centrifugal pumps based on the ASME Power Test Codes:

- Efficiency

- Head – suction, discharge, and total

- Net positive suction head

- Deviation from design efficiency

- Deviation from the design head

- Deviation above required net positive suction head

Measurement instrumentation required to use this algorithm includes suction temperature, discharge temperature, suction pressure, discharge pressure, flow, power, and speed (for variable speed pump motors). Design information for the pump is also needed. This information includes suction inner diameter, discharge inner diameter, suction elevation, discharge elevation, motor design efficiency or motor nameplate data, and pump design curve.

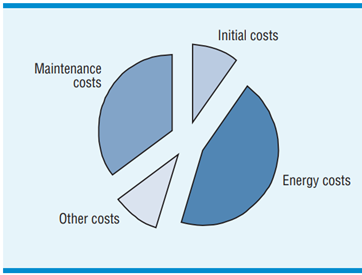

Pumps are a significant source of operational costs from initial procurement costs, ongoing energy costs to operate, and maintenance costs to service and repair. The U.S. Department of Energy figure shows the typical lifecycle costs for a medium-sized pump.

Pumps are a significant source of operational costs from initial procurement costs, ongoing energy costs to operate, and maintenance costs to service and repair. The U.S. Department of Energy figure shows the typical lifecycle costs for a medium-sized pump.

Due to pump affinity physics, variable-speed motors can achieve significant energy savings. The speed and power of a pump have a cubic relationship cube law relationship. This means reducing the speed and energy savings by 30% to 50%. Therefore, reducing motor speed can result in considerable energy savings.

Due to pump affinity physics, variable-speed motors can achieve significant energy savings. The speed and power of a pump have a cubic relationship cube law relationship. This means reducing the speed and energy savings by 30% to 50%. Therefore, reducing motor speed can result in considerable energy savings.

The Pump Performance Algorithm and Ovation Logic Solutions enable the tracking of energy costs for each pump by the month. It also tracks the total flow of the pumps.

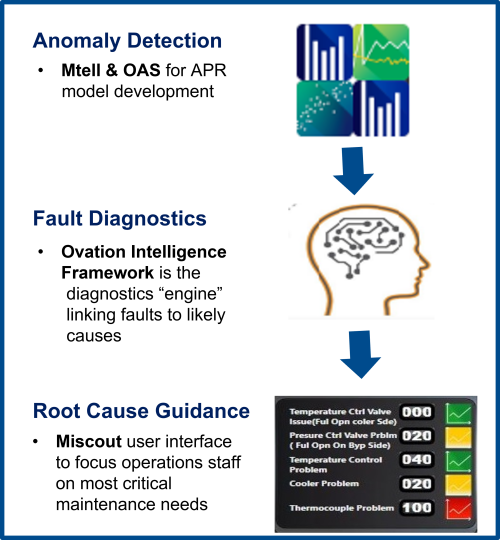

These pump performance outputs can be used as inputs to the Ovation Predictive Analytics application. These analytics can help predict anomalies, perform fault diagnostics, and provide root cause guidance.

In summary, the pump performance algorithm is an APC Toolkit algorithm that runs at Ovation 3.8 and higher. It:

- Calculates the head and efficiency of the pump

- Shows deviations from design efficiency and design head

- Uses efficiencies and head trends to detect maintenance issues

- Uses efficiencies and heads to input data analytics and detect pump issues

- Adds Ovation logic to track starting statistics, runtime, and pump costs on an hourly, daily, and monthly basis

Visit the Ovation distributed control system section on Emerson.com for more information on driving pump performance improvements.