Many maintenance teams are facing a two-pronged problem these days. As their organizations expand and acquire new plants across the country or even across the globe, teams are responsible for managing an ever-increasing number of tools and software packages to manage the health of their assets. In addition, as they use that equipment to monitor their assets, they are constantly gathering more and more data that they need to analyze to track, trend, and improve plant health. However, that data can easily get trapped as it traverses organizational hierarchies.

Couple these issues with the fact that many maintenance teams are struggling to find experienced personnel—ultimately forcing them to run a very lean staff—and maintaining long-term operational excellence quickly becomes a herculean (if not impossible) task.

But all is not lost. As Emerson’s Erik Lindhjem and Nina Golder point out in their recent article in Hydrocarbon Engineering (pages 49-52), lifecycle maintenance tools can help maintenance teams manage the health of their automation assets to build a more navigable and sustainable maintenance and reliability program. Putting the right tools in place not only helps teams keep tabs on the status of all their essential maintenance tools, but also helps them build toward a Boundless Automation vision of maintenance and reliability—democratizing data to make it accessible and usable at every level of the organization.

With growth comes complexity

Large organizations can easily have hundreds of critical maintenance tools, such as handheld devices, across their many plants. Moreover, as those organizations grow, they frequently acquire other plants that add equipment, some the same, some different, to the inventory. As Erik and Nina explain, managing those tools can quickly become unwieldly,

“Confirming all those devices and systems are updated is a task that cannot reasonably be performed on paper—especially across an organization running with a lean and remote staff. To do so would mean keeping up-to-date records of the most current status of all devices and systems, which would take many hours of onsite work at each plant, and the process would have to begin from scratch each time a new update was released.”

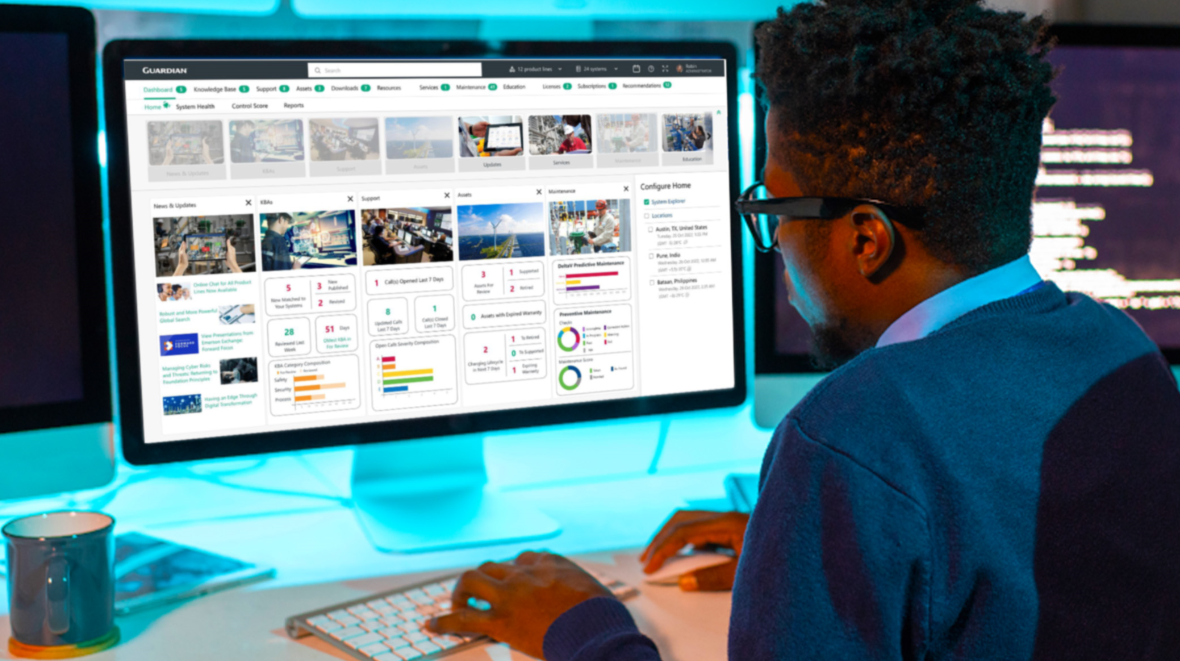

Fortunately, enterprise-level portals for asset management can close the gap on complicated asset maintenance. Emerson’s Guardian, for example, collects data from devices and systems across the enterprise and displays it in a single, intuitive user interface, empowering personnel to instantly see the status of their machinery health software and maintenance devices in every plant. But the value doesn’t end there,

“Moreover, instead of having to sift through individual parameters—such as software versions, firmware version, patches and updates, and more—users can opt for system or device level key performance indicators (KPI), such as a health score ranging from 1-10, making it easy to see exactly which units need attention. Furthermore, these KPIs can be rolled up such that it becomes easier to see which plants, locations, business areas, or geographic areas need attention.”

With growth comes more data

As additional devices and assets across the enterprise become more manageable, organizations will continue adding them. Each device has the capacity to transmit a lot of data, and that data adds up quickly. But if all the organization does with the data is dump it into a centralized repository and forget about it, the company’s data lake will quickly become a data swamp. Avoiding this problem is at the heart of Emerson’s Boundless Automation vision. Forward-thinking organizations are using Emerson’s next-gen automation technologies to seamlessly connect systems from the intelligent field to the edge and into the cloud to drive maintenance innovation. Technologies like AMS Asset Monitor, AMS Machine Works, AMS Optics, and the AMS Device Manager Data Server are helping them maintain the context around this data so it is continually standardized and properly organized in real-time for use by high-level enterprise analytics.

Prepare for the data-rich future

As Erik and Nina explain, using lifecycle maintenance tools to better manage data not only pays dividends in improved long-term operational excellence, but also helps organizations draw and retain the best talent. More and more of the personnel available today are expecting connectivity across operations and intuitive, data-rich tools to help them better perform their jobs. Those tools are available, and they are driving competitive advantage for the organizations savvy enough to use them.

To learn more, read Nina and Erik’s article in its entirety over at Hydrocarbon Engineering.