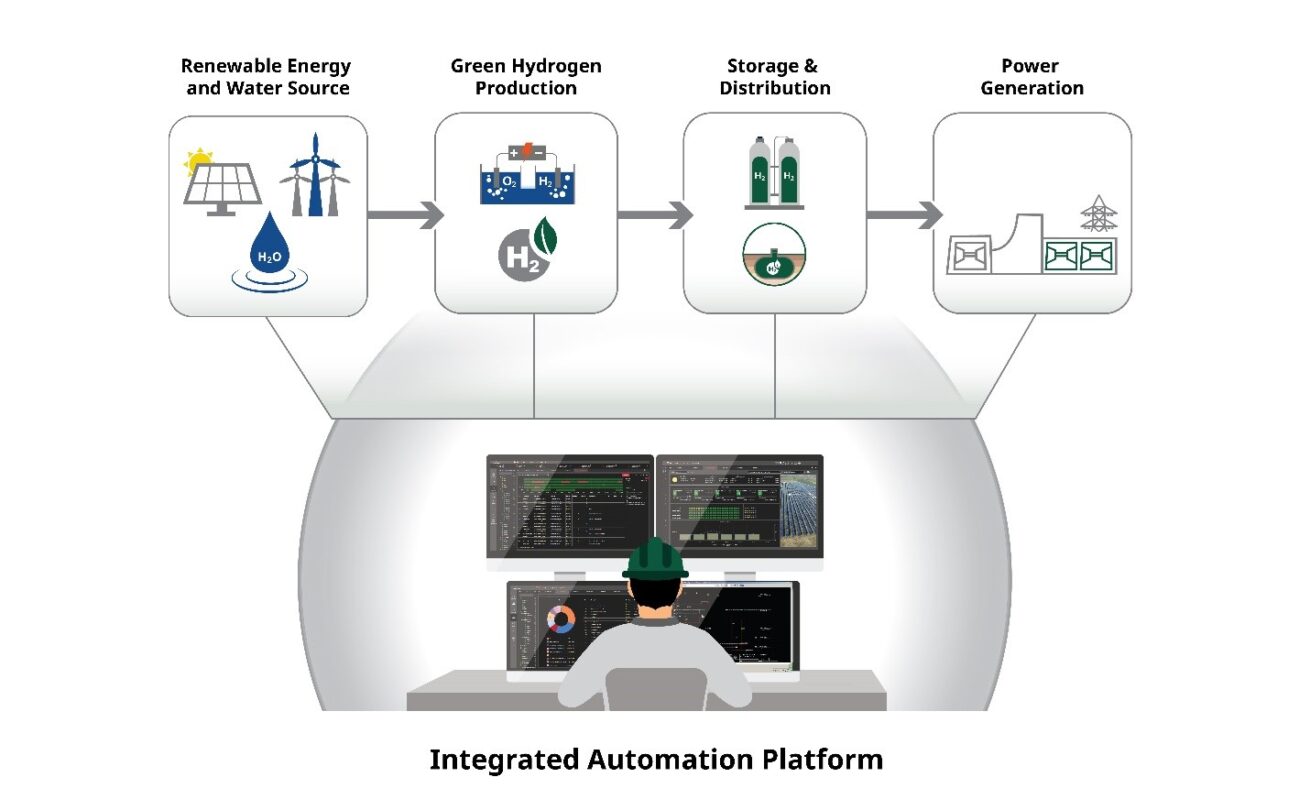

Of all the new sustainable technologies emerging in the energy marketplace, one of the most exciting is green hydrogen. In an era of increasing focus on sustainability, green hydrogen has the potential to provide clean power for manufacturing, transportation, and more, and its only emission is water. But while the possibilities for use are limitless, the value chain for green hydrogen manufacturing is incredibly complex.

Manufacturing green hydrogen requires companies to use energy from renewable sources—wind, solar, hydro, etc.—which means finding reliable sources for that green energy generation. And once it is created, the hydrogen must be transported and stored, a process that requires rebuilding or retooling of transport and storage networks across the globe. But storing isn’t enough. That stored hydrogen needs to be transported again to a place where it can be used—typically an end-user distributor or a hydrogen-capable power plant, both of which are technologies that are still in their infancy.

But the uncertainty of hydrogen operations is also what makes them so appealing. The technologies are not yet proven, so the risk is high. However, as is the case with any high-risk endeavor, the potential rewards are high too, for teams bold enough to chase them. Yet, as Lauren Wherry explains in her recent article in Global Hydrogen Review (page 54), even with all the unknowns, success is very achievable when organizations follow a few essential strategies:

- Implement an open, unified control platform across the value chain.

- Leverage the data from a unified platform with simulation tools.

- Partner with energy industry automation experts for comprehensive guidance.

The benefits of cohesive control

When teams pursuing new technologies like the hydrogen value chain begin their engineering, they typically have many different options for control. However, connecting many systems from a wide array of suppliers often leaves teams with a complex spider web of engineered interfaces. That complex web is often fragile and can trap critical data in silos. Unified control, Wherry explains, is a much more effective strategy,

“A single control platform provides increased ease of use because all systems across the value chain have the same historical retrieval process for data capture, making it easy to trend and analyze data for improved operations. Moreover, trip reporting, alarm reporting, and root cause analysis are all presented in a unified format and come from the same system, increasing operational awareness. This standardization of data provides operators with a consistent and cohesive interface, helping them isolate critical information more quickly to make better, safer decisions. Operators only need to be trained on a single interface to be effective anywhere in the value chain.”

A single, cohesive automation solution helps improve operational efficiency.

Because nobody has the green hydrogen value chain perfectly dialed in yet, teams are constantly reviewing and revising their operations for the safest, most efficient, and most profitable performance. In fact, few users of green hydrogen will use 100% hydrogen from the outset—instead opting to blend small percentages of hydrogen with another fuel source and gradually increase the ratio over time.

To make such changes safely, operators cannot run tests on live equipment. Instead, they rely on simulation tools such as a digital twin. In most cases, Wherry shares, they will have the best success with a high-fidelity digital twin with embedded modeling from the control system. Using simulation tools built on the same technology as the control system means that users will have a unified set of tools and interfaces across their technologies, empowering them to change processes and equipment and see exactly how adjustments will impact their operations.

Expertise makes all the difference

When navigating the green hydrogen value chain, choosing an automation partner is about more than just selecting any single vendor. Typically, green hydrogen processes will need to interact with other industrial processes, whether it is complex storage and transport networks, distribution to end users, or integration with power plants trying to maintain a stable grid. The best automation partners offer end-to-end technology solutions, from intelligent field through the edge and into the cloud, built on a foundation of decades of industry expertise. Wherry explains,

“The best automation solution providers offer systems that make it easy to move information from the entire value chain up to the enterprise. Plus, these systems also typically offer integrated industrial software solutions to simplify connection to the grid. An expert provider with hydrogen expertise and decades of power industry experience can help organizations more easily design, implement, and maintain first-of-their-kind projects across the lifecycle.”

For example, Emerson’s Ovation Green software platform helps organizations optimize renewable energy asset operations across the entire hydrogen value chain. With simplified renewables automation and clear visibility from a single pane of glass, green energy teams can more confidently navigate the complexities of their operations across the entire lifecycle.

To learn more about the green hydrogen value chain, read Lauren Wherry’s article in full at Global Hydrogen Review.