Matthew Wagner, Emerson Flow Products Chemical Industry Manager recently published an article in the August 2022 issue of Hydrocarbon Engineering. It is titled “Control Valve Selection for Ethylene Plants,” and it describes how to choose the right combination of valve style, trim type, materials of construction, and digital positioners for critical valve application in an ethylene unit. A summary of the article follows.

Ethylene is one of the most mass-produced petrochemicals in the world. Initially formed by steam-cracking naptha or natural gas liquids, the product is isolated and refined and sold as an intermediate feed for plastics and other specialty chemical products. This article highlights the critical design features of the more difficult control valve applications in ethylene production.

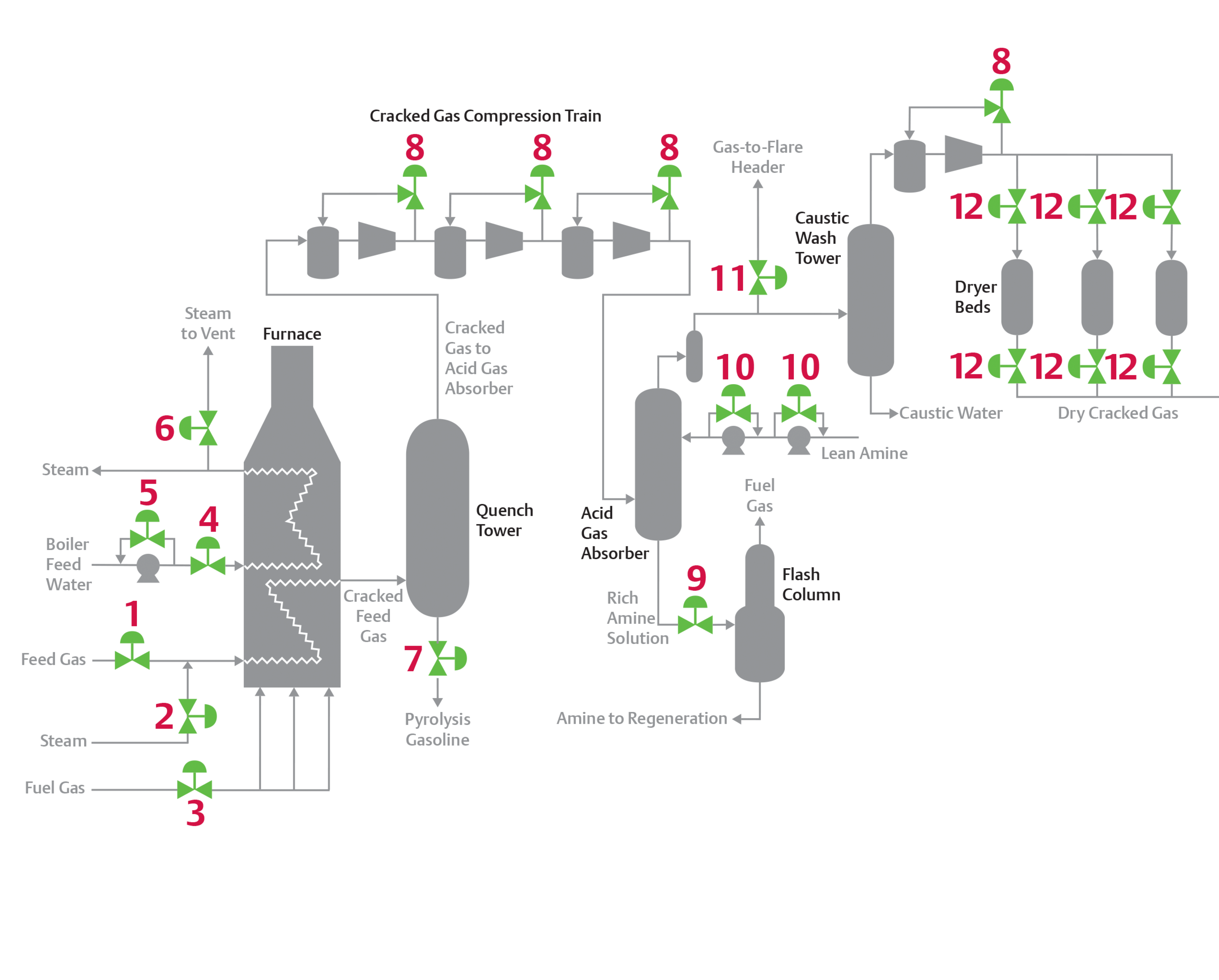

The ethylene process – warm section

An ethylene plant can be divided into the front end “warm section” and a back end “cold section.” The warm section (Figure 1) starts with a cracking furnace where naptha or natural gas is mixed with steam and subjected to very high temperatures. This fractures the hydrocarbon into many components (ethylene, propylene, acetylene, etc.), and the gas mixture is quenched to stop the reactions, then compressed, and finally run through various vessels to remove acids and water.

Proper operation of the cracking furnace depends upon three major valves: the hydrocarbon feed valve (#1), the dilution steam ratio valve (#2), and the burner fuel control valve (#3).

Figure 1: This flow diagram focuses on the front end “warm section” of the ethylene process. Major equipment includes the cracking furnace, quench tower, gas compressors, acid removal section, and dryer beds. (Click to enlarge)

All of the furnace valves must provide very tight flow control, so high-performance globe valves with diagnostic positioners and environmental packing are the norm.

The quench tower quickly cools the furnace gas. If naptha is the feedstock, then oil is used as a heat transfer fluid and it tends to fill with carbon particles. As liquid passes out the bottom of the vessel, the quench tower level valve (#7) is subjected to a punishing, erosive slurry. Matthew suggests the following for this valve:

Hardened trims, such as Alloy 6 or ceramics, and sealed metal bearings are used to protect the valve internals and lengthen service life. Environmental packing is still required, and most operating units employ diagnostic positioners to sense and indicate developing problems well in advance of failure.

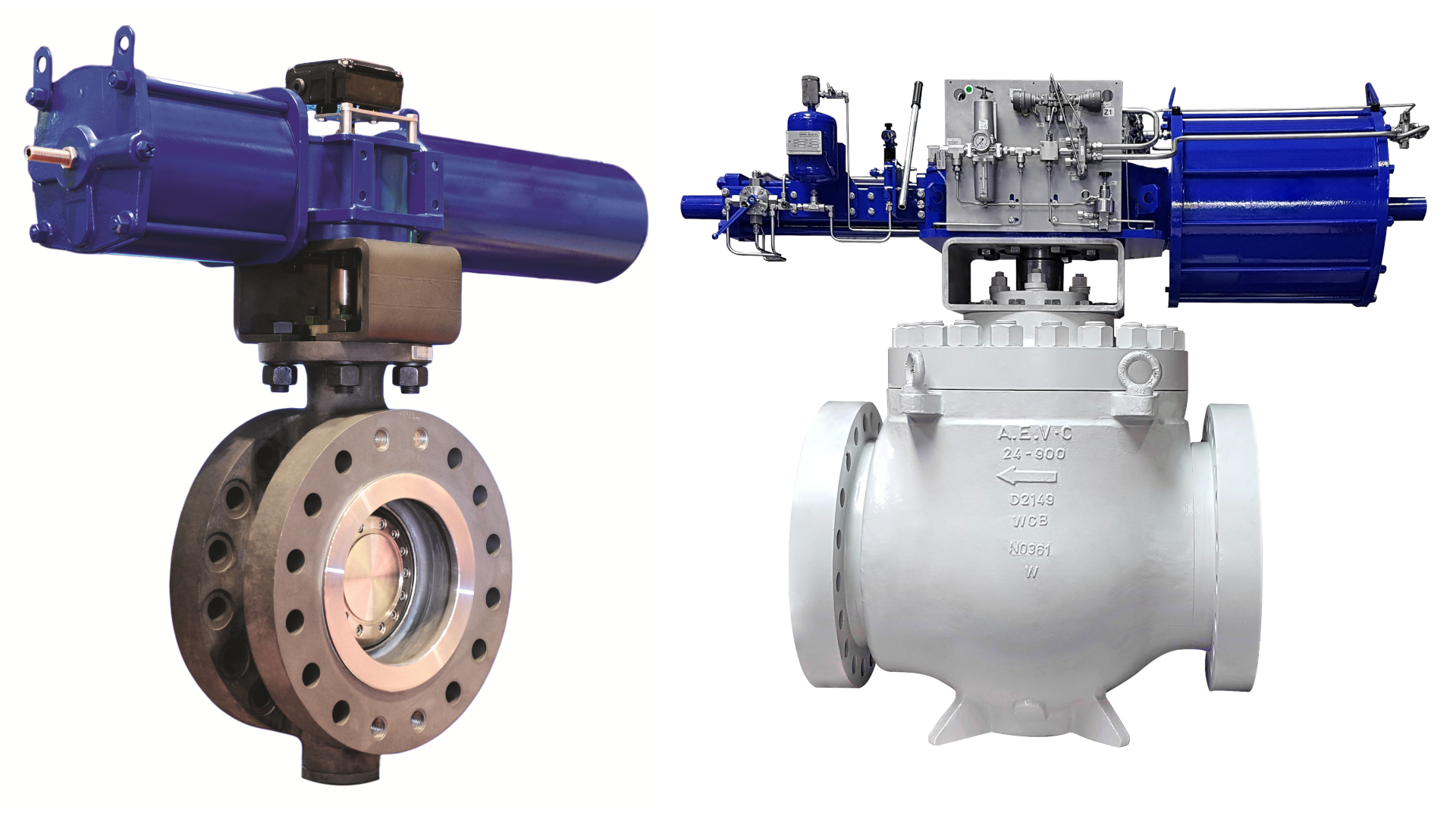

As the gas leaves the quench tower, it is compressed to feed the next processing stages. Each compressor stage depends upon the anti-surge valve (Figure 1 – #8) to protect the equipment from catastrophic damage during low gas flow. These valves (Figure 2) may be very large and must endure the full compressor pressure drop during normal operation.

Figure 2: An anti-surge control valve, like this Fisher Optimized easy-e™ EWT, is a critical component of an anti-surge control system.

Anti-surge valves are usually customized with pneumatic boosters, actuators, and very high speed and precision diagnostic positioners to meet the required performance specifications.

After compression, the process gas enters the acid gas absorber which uses amine to strip acidic gases. In this area the most critical valve is the rich amine letdown control valve at the bottom of the acid gas absorber (Figure 1 – #9). Matthew describes this service:

This valve is subjected to high pressure drop by design so that the entrained acidic gases separate from the rich amine solution, allowing it to be recycled. This type of separation is known as out-gassing, and it generates noise, vibration, and erosion.

The internals of this valve must employ hardened trim materials, anti-cavitation trim, and environmental packing. A diagnostic positioner is often used to detect and alarm as the valve develops the inevitable trim damage associated with this very difficult service.

After acid removal, the process gas enters the drying section. Multiple molecular sieve beds are alternately switched in and out of service to dry the gas and regenerate the beds. The dryer switching valves (Figure 1 – #12) must endure high cycle rates and high temperatures, yet allow virtually zero leakage.

The best valve designs will usually require quickly stroking double eccentric ball valves or high-performance triple offset valves (Figure 3). Diagnostic positioners are used to detect developing valve problems well in advance of failure.

Figure 3: Triple offset valves (left) and double eccentric C-ball valves (right) are excellent choices for severe service applications requiring zero leakage, such as ethylene dryers. (Vanessa™ Series 30,000 Triple Offset and AEV™ 2XC C-ball valves shown.)

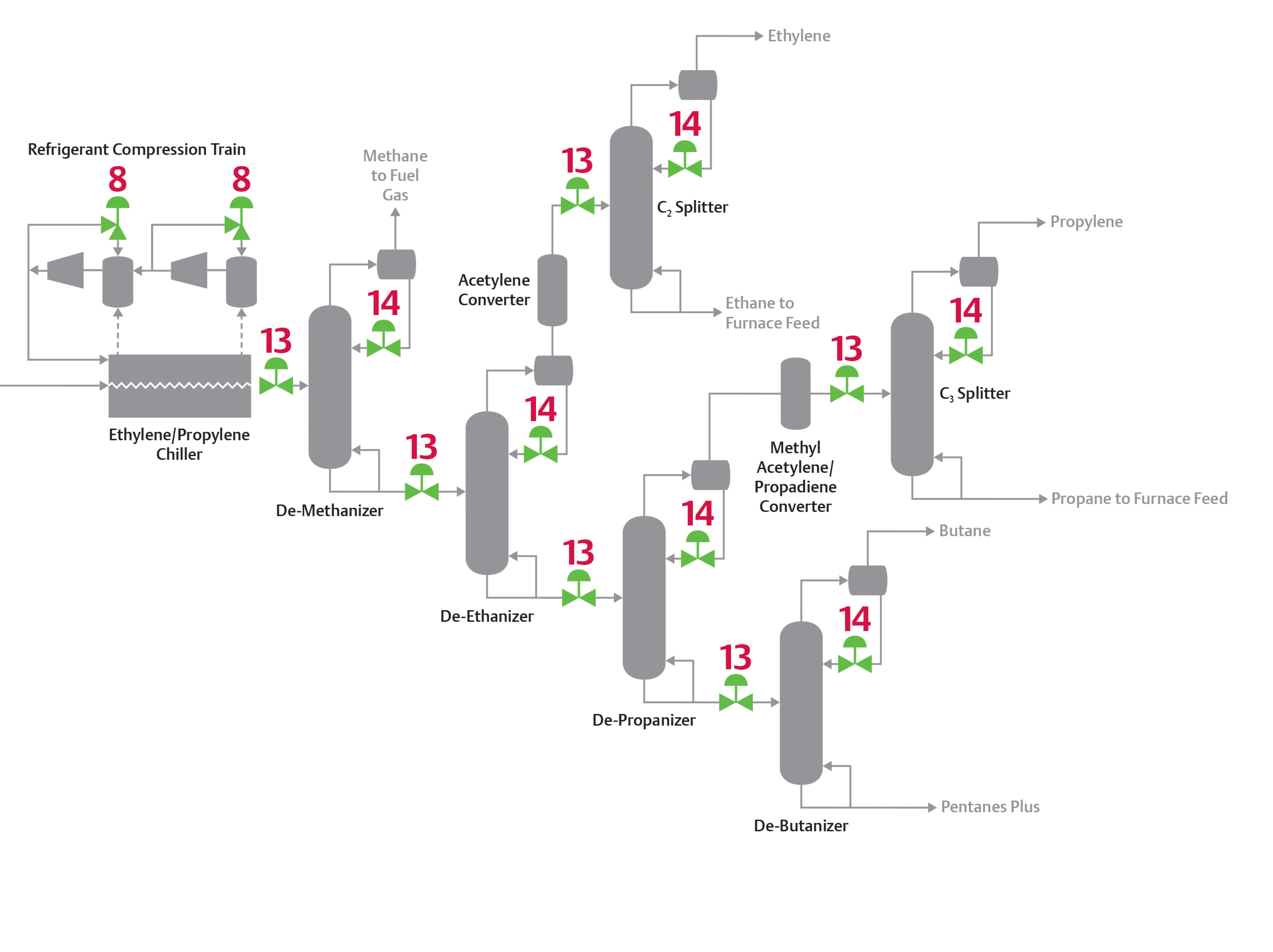

Critical cold section control valves

The back of an ethylene plant (“cold section” – Figure 4) chills the product stream and uses a series of distillation columns to isolate the ethylene. Very precise flow control is critical for distillation column operation, and the major valves in this section include the distillation feed control valves (#13) and distillation reflux control valves (#14).

Figure 4: In the back end “cold section” of the process, ethylene is refrigerated to very low temperatures, and then passed through a series of distillation columns to separate and purify the process streams. (Click to enlarge)

Some columns in this process run at cryogenic temperatures, so control valve trim and soft parts must be selected carefully. The valves must be accurately sized to provide consistent and stable control, and the valves themselves are usually high performing globe valves with diagnostic positioners and environmental packing.

Matthew concludes his article with this advice:

The number of available design options are extensive, so end users may find it helpful to consult with their valve vendor to determine the best valve type, packing, materials of construction, and digital positioner for their specific application.

Visit the Ethylene, Control Valves, and Isolation & Shutoff Valves section on Emerson.com for more on the technologies and solutions to help you drive ethylene process performance improvements.