We hear a lot about reliability these days. Sensors have become more affordable, software has become more powerful, and teams are more reliant on automated monitoring to ensure unexpected failures don’t disrupt production. However, as Nina Golder shared in a recent article in Hydrocarbon Processing, there is an often overlooked area of plant health that needs to receive more attention: the control system.

Maintaining reliable operation means not overlooking the health of the control system.

The control system is one of the most reliable technologies in the plant, and because problems are rare—and often hard to diagnose—they often go unnoticed. This is also compounded by the fact that for many years, control system monitoring technologies were complex and expensive to implement, so teams typically focused their efforts elsewhere. However, in today’s more competitive marketplace, plants are looking to squeeze every ounce of efficiency out of plant equipment, and that means finally turning their attention to the control system. Fortunately, as Nina explains,

“With much less time and complexity than previously imagined, teams can now implement a predictive maintenance solution that will provide the peace of mind of reliable automation operation, along with the flexibility, freedom and visibility necessary to improve plant performance.”

Fewer people, more problems

One of the key reasons plants did not often pursue control system monitoring technologies is they had the personnel available to perform regular routine maintenance on their systems. But that routine maintenance is reliant on a deep bench of highly experienced personnel. The maintenance activities for control technologies are complex, requiring experience that takes years to develop. Many of today’s plants no longer have the necessary long roster of experienced personnel to commit them to these routine activities.

Even if a plant has the personnel required for routine control system maintenance, it is still very easy to miss issues with the system if the team relies on traditional maintenance rounds. As Nina explains,

“If a problem begins right after maintenance, then it will likely be some time before that problem is noticed, thus creating the potential for a trip. Operating exclusively under a routine maintenance strategy means that such problems can be missed until the system is checked again.”

Simplification through software

Today’s best-in-class control system monitoring technologies are entirely software based. They are easy to install and maintain, no longer requiring specific appliances, specialized hardware, and complex software. In fact, the best solutions can now be installed in less than an hour by the plant’s own personnel, and they will continuously monitor the control system with little effort on the part of the staff.

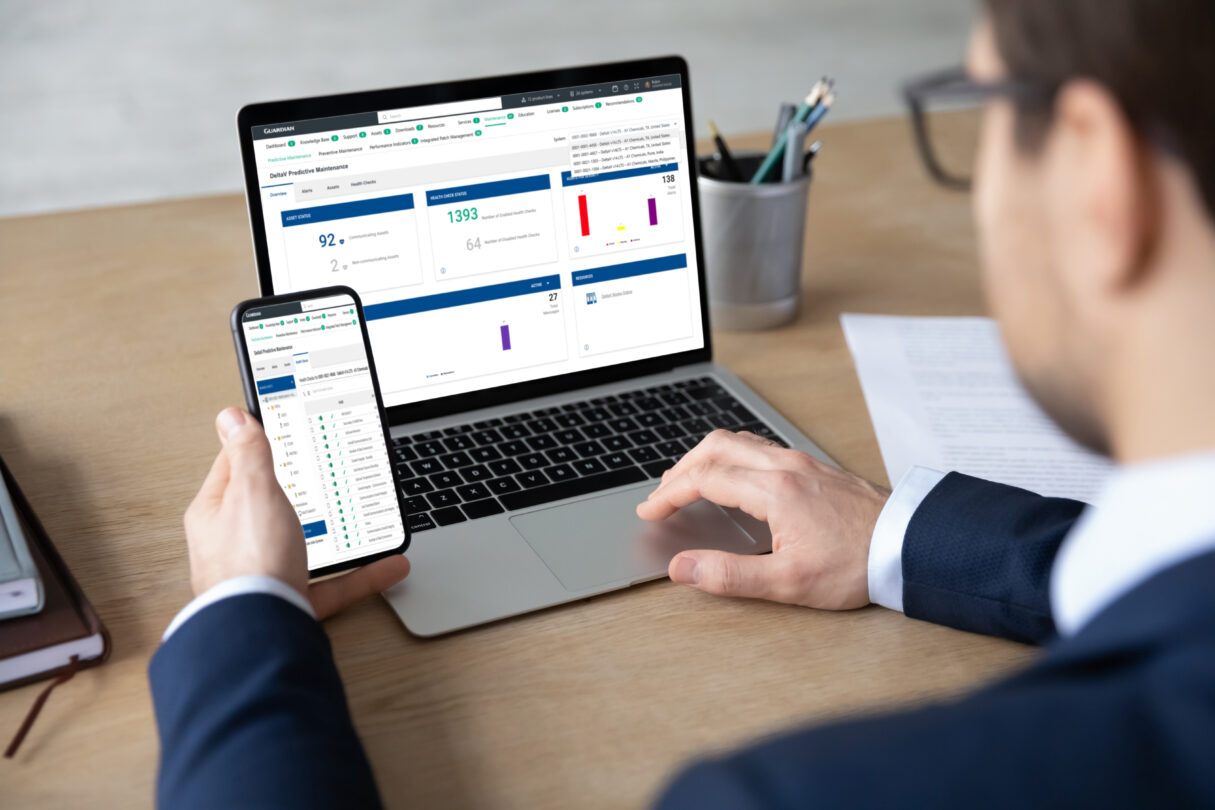

Control system predictive maintenance technologies untether personnel from the control room and improve enterprise visibility of control system health.

Control system predictive maintenance software helps teams maintain constant visibility of the health of the control system without tying them to the control room. Personnel can receive real-time alerts for potential issues—with the severity clearly indicated—wherever they may be. And powerful built-in analytics can help provide decision support and identify root cause of problems to assist and upskill plant personnel of any level.

Those alerts, Nina explains, are critical to successful operations.

“Real-time alerts also increase the likelihood that essential work will be performed on schedule. In a routine maintenance setting, visibility of plant issues is typically limited to the person who ran the diagnostic. However, with predictive maintenance, multiple staff—including maintenance managers—can receive alerts. Scheduling and expediting become much easier, and problems that might not trip the plant, but still impact productivity, are less likely to be ignored.”

The DeltaV Predictive Maintenance offering will be available soon. Until then, you can read the article in full at Hydrocarbon Processing magazine. Nina shares many examples and best practices to help you adopt the right predictive maintenance technologies for your unique application.