In an Industrial Heating article, Emerson’s Andrew Smith breaks down the complexities of combustion control, and provides a solution

Some industrial processes prove to be more complex in actual operation than they first appear. One of the most common is combustion, as applied with boilers, fired heaters, ovens, and the like. Conceptually, it is very easy to understand: mix fuel with air in the right proportion and it works. Well, yes, but it isn’t always that simple.

Fuel, even natural gas, isn’t always completely consistent, and while we’re using air, what we really need is oxygen, but all that extra stuff (nitrogen, etc.) still has to come along for the ride and complicate the mix. How operators work in that environment and strive to achieve the most desirable outcome is the topic of my article in the June issue of Industrial Heating, Better Flue Gas Analysis Improves Combustion Control.

Combustion analysis invariably begins by putting an oxygen sensor in the flue gas stream. Its purpose is to determine if too much air is being pushed into the system, reducing heat-recovery efficiency. If there is very little “excess” oxygen, combustion is efficient, right? Yes, but the true excess amount is difficult to determine from a basic oxygen sensor reading alone.

With the right type of oxygen sensor, it is possible to determine how much of the oxygen in the stack is part of the stoichiometric amount, which is left over due to less-than-perfect combustion, and which is truly excess oxygen. A zirconia sensor has a particular characteristic that allows it to measure only true excess oxygen. Flue gas flowing into the sensor includes both oxygen and any unburned fuel. Given the high temperature and high surface area of the sensor’s platinum beads, combustion of any remaining fuel traces is completed through catalytic oxidation. So when the fuel is consumed, the stoichiometric oxygen is consumed with it. Since all combustion is completed, any oxygen still measurable represents excess oxygen.

Emerson’s Rosemount 6888 In Situ Oxygen Analyzer is just that kind of sensor. It provides a continuous, accurate measurement of oxygen in flue gases coming from any combustion process. Accurate measurement of excess oxygen is critical to optimize the combustion reaction, resulting in reduced energy costs, increased safety, and lower emissions. Still, this measurement alone does not provide the date required to determine if the combustion is excessively rich because it can’t determine the amount of unburned fuel present. Combustion often ends up being too rich because operators turn the air flow down too much, hence the need for a second measurement.

More sophisticated combustion analyzers begin with a zirconia oxygen-sensing element and add a second stage: a catalytic bead sensor designed to measure residual combustible gases, including carbon monoxide and hydrogen. Presence of these represents unburned fuel or only partial combustion. This sensor technology combination is robust and able to withstand difficult environments, including the presence of pollutants such as sulfur dioxide.

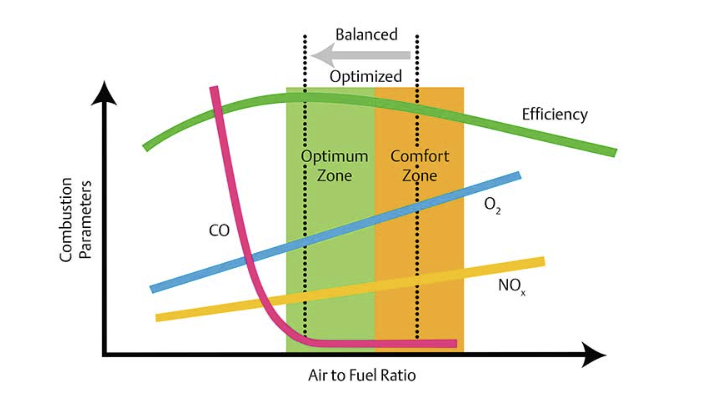

Again, Emerson has that kind of analyzer. The Rosemount OCX8800 Combustion Flue Gas Transmitter provides a continuous, accurate measurement of the oxygen and combustibles remaining in flue gases from a combustion process. With that data, it is possible to balance oxygen and unburned fuel to achieve a higher degree of efficiency and optimization. But there is still one more element: emissions. For that last bit, you’ll have to read the article. Suffice it to say, for combustion processes, efficiency and optimization are not always achieved simultaneously, but with enough data, it is possible to operate exactly where the application needs to be.

The key is having all the data necessary for making critical evaluations, and this calls for analyzer technology capable of delivering a full picture of the process. When there is only an oxygen measurement, much is left to guesswork. Operators may reach a comfortable point, but it might be far from optimal. True optimization – possible with the right analyzer technology – creates a balance between low fuel costs, process effectiveness, managed emissions and a safe workplace.

Visit the Combustion Analysis pages at emerson.com. You can also connect and interact with other engineers in the Industrial Energy & Onsite Utilities, and Power Generation Groups at the Emerson Exchange 365 community.