Emerson’s Dave McMillen presents New Developments in CEMS Analysis using Quantum Cascade Laser Spectroscopy at the 4C HSE conference in Austin, Texas. Here is his abstract:

Emerson’s Dave McMillen presents New Developments in CEMS Analysis using Quantum Cascade Laser Spectroscopy at the 4C HSE conference in Austin, Texas. Here is his abstract:

The application of Quantum Cascade Laser based analyzers to CEMS [continuous emissions monitoring system] provides improved analyzer availability and reduced maintenance. The stability of QCL and TDL semiconductor Lasers and the inherent nature of analyte spectral absorption is the foundation of this improved performance. The added capability of operating at temperatures up to 190C and running Hot/Wet adds further simplicity and lower operational costs. This talk will explain the technology and the benefits of QCL/TCL spectroscopy for CEMS.

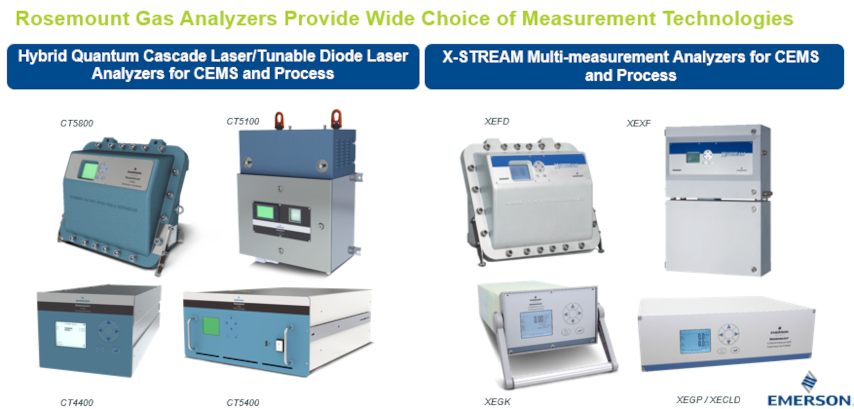

Dave opened by sharing the history of Quantum Cascade Laser Analyzer technology and why QCL is used in the process industries. The timeline began in 2003 with intensive research & development, patents and QCL intellectual property development. The first commercial systems were launched in 2011 with improvements and new models launched since then.

QCL works by having the laser module provide specific wavelengths. Measurements are made by using absorption spectroscopy. These continuous gas analyzers can used in a number of measurement applications in industrial processes.

When power is applied the QCL heats up. As the temperature increases, the laser wavelength increases. The laser sweeps the frequencies where components of interest absorb. The Peltier cooler built into laser package cools the laser back down to the starting temperatures. Each “chirp is under 1 millisecond enabling thousands of spectra collected per second.

The laser module is tuned to a particular wavelength range and it contains unique information for the laser. CEMS applications for QCL can be used in cold/dry and hot/wet environments. In cold/dry applications, the sample is transported at temperatures above the dew point of the flue gas. The chiller condenses the liquid in the flue gas down to around 8,000ppm and the measurement is reported on a dry basis. The analytes that are miscible in water are lost in the chiller.

In hot/wet applications, the sample is transported at temperatures above the dew point of the flue gas. There is no chiller to condense liquid out of the flue gas. The analytes that are miscible in water are not lost in the chiller and the measurement is reported on a dry basis with a correction from the water measurement.

Dave summed up the advantages of QCL and TDL (tunable diode laser) technology as excellent in low concentration resolution and high-temperature operation. The reliability and analyzer availability and maintenance needs are low since the lasers are extremely stable and the absorption areas of analytes are fixed by the laws of physics. There are no moving parts and calibration is not needed under normal circumstances. Validation is typically performed monthly and one analyzer can replace many with multiple QCL and TDL capabilities.

Visit the About Quantum Cascade Laser Analyzers on Emerson.com for more on QCL technology in CEMS and other measurement applications.