Today’s plants frequently have limited personnel but still need to find ways to do more work and meet increasing goals and quotas. This dichotomy frequently causes a problem when it comes to asset monitoring, which is traditionally performed by technicians manually inspecting equipment with handheld devices on a regular schedule. In the current environment, plants are faced with a dilemma: do they reduce the manual rounds and commit personnel to other critical tasks with more immediate impact, or do they ensure critical maintenance rounds are completed at the expense of other maintenance needs?

Fortunately, today there is another solution. As Emerson’s Drew Mackley and Shane Moser explain in their recent article in InTech, many plants are moving to automated asset management to optimize planning and reduce costs through increased predictive maintenance. However,

“asset management technologies implemented without a plan have the potential to generate problems that complicate maintenance in new ways. To avoid these problems, organizations striving for the best performance must carefully plan system implementation based on a foundation of integration—among technologies and key stakeholders, and with business enterprise systems.”

So much data

As plants add more devices to their infrastructure, they gather more and more data. This can be a blessing, but only if that data isn’t siloed by a wide range of software and protocols, and as long as it doesn’t create more manual labor, requiring technicians to sift through mounds of data to identify issues in the plant.

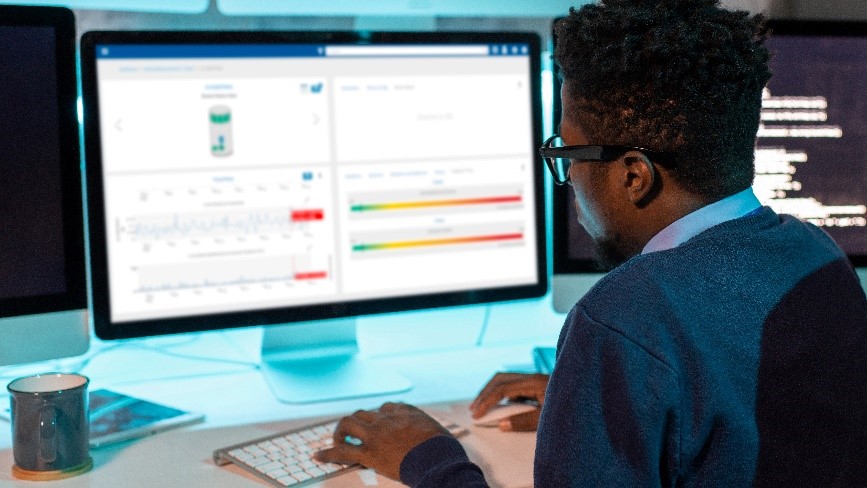

AMS Machine Works aggregates data from multiple monitoring technologies to help diagnose machinery health issues.

Drew and Shane identify how machinery health software can be a critical enabler of better automated monitoring,

“To speed ROI, plants are turning to machinery health software packages that can collect data from many types of devices, perform local analysis, and export critical values. These software packages analyze aggregated data from multiple monitoring technologies to make an early diagnosis of developing issues and to help users identify root causes and isolate problems before they become severe. Information is presented intuitively in a single location, so users do not need to search through mountains of data, potentially in a variety of disparate systems.”

Keeping communication open

Moreover, machinery health software can be an enabler of better collaboration across the plant. Machinery health software delivers data relevant to a user’s unique role in the plant with intuitive displays showing machine status at a glance. These tools connect users with the other technicians in the organization who can share

“established workflows and instant access to manuals, video walkthroughs, knowledge bases, and more to rapidly upskill new and experienced personnel.”

And these same tools can help move critical data up the organization to provide better visibility at the enterprise level for plant-level analytics driven by corporate initiatives. Machinery health platforms can convert machine data into cloud-ready information to be shared across the organization via data repositories, where it can be accessed by enterprise cloud systems for advanced analytics.

Machinery health software can help move critical information for better visibility by anyone in the enterprise.

Today’s tools build a more efficient mobile workforce

Emerson’s AMS Machine Works collects data from equipment across the plant and enterprise and presents it in a single location to help personnel of all experience levels more easily monitor, manage, and maintain the equipment in their plant.

You can learn more about how moving to 100% automated monitoring can help your mobile workers improve efficiency and ROI by reading the article in its entirety. And while you’re here, I’d love to hear your strategies for making the most of a small workforce on the plant floor!