Given the weather extremes we’ve experienced here in the U.S. in recent weeks, manufacturers and producers with outdoor production facilities need accurate and self-diagnosing instrumentation to assure reliable operations. Level measurements are one critical area where this is especially true.

Given the weather extremes we’ve experienced here in the U.S. in recent weeks, manufacturers and producers with outdoor production facilities need accurate and self-diagnosing instrumentation to assure reliable operations. Level measurements are one critical area where this is especially true.

In a Flow Control article, Advanced level instrumentation improves performance and safety, Emerson’s Nicole Meidl and Megan Wiens share how the right transmitter technology in differential pressure (DP) level measurement instruments can reduce or eliminate maintenance problems and deliver better process information.

Level measurements are often used to prevent overfill conditions which may lead to safety and environmental incidents. While avoiding these incidents is paramount, Nicole and Megan note other potential problems such as:

- Ineffective feedstock and finished product inventory management

- Production interruptions if feedstocks run out unexpectedly

- Inefficient use of storage resources

Traditionally, mechanical level monitoring mechanism such as float-and-tape setups have been used. DP level measurements avoid mechanical components. The density of the liquid being measured will affect the DP reading, so the instrument will need to be calibrated for the liquid density.

For sealed tanks and vessels, they:

…can experience internal system pressure above or even below atmosphere. If a large tank holding water and vented to atmosphere shows a pressure reading on a simple pressure gauge of 15 pounds per square inch (psi), it is correct to assume there is 34.6 feet of water above the gauge. If the tank is not vented and it is pressurized to 5 psi, the reading will change drastically. The offset can be corrected by deducting the system pressure, but the easier approach is using a DP gauge and tying the low side to the headspace. This makes the reading self-correcting.

Impulse lines are typically used for the connections to measure the two pressures. These allow:

…the contents to reach a bourdon tube or internal diaphragm. Of course, this makes the gauge or transmitter and the impulse lines part of the tank’s containment, which can become a maintenance headache with potential for leakage.

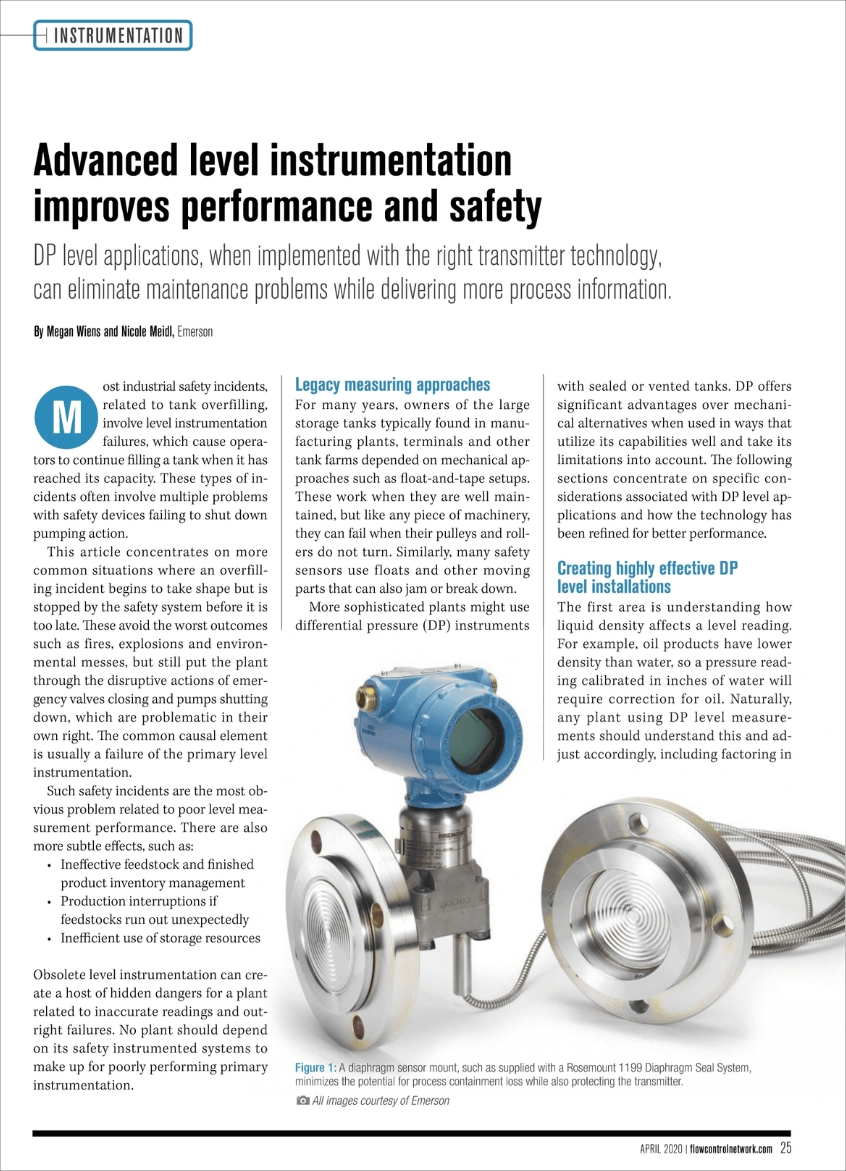

To avoid this problem, the:

…solution is to install a remote diaphragm seal [such as a Rosemount 1199 diaphragm seal system] at the tank connection, which isolates the contents while sending pressure readings to the gauge or transmitter via a sealed line filled with silicone oil or other fluid. This wet leg approach eliminates most of the maintenance problems, but can introduce concerns of its own, particularly with tall tanks.

Read the article for ways to address these concerns through methods such heat tracing or using Rosemount 3051S Electronic Remote Sensor (ERS) systems. Nicole and Megan also describe how embedded diagnostics help identify and avoid wiring problems such as leakage current and increased electrical load.

Visit the Differential Pressure (DP) Level Measurement section on Emerson.com for more on this technology and ways to ensure accurate and reliable level measurements. You can also connect and interact with other level measurement experts in the Measurement Instrumentation group in the Emerson Exchange 365 community.