In introducing our Rosemount™ 8800 Series Vortex flow meters, we’ve talked about how this technology is uniquely suited for superheated steam applications, delivering better control in these challenging environments than anything else on the market today. More specifically, we designed our 8800 MultiVariable Vortex flow meter to pair with an independent pressure transmitter to provide the ultimate multivariable vortex solution. By utilizing an integrated temperature sensor and connecting the 8800 MultiVariable meter to a HART® pressure transmitter, such as a Rosemount 3051S In-Line Pressure transmitter, the assembly offers unparalleled accuracy and reliability for pressure compensated mass flow in saturated steam applications and pressure and temperature compensated mass flow in superheated steam applications.

How Does the Pressure Transmitter Communicate with the 8800 MultiVariable Flow Meter?

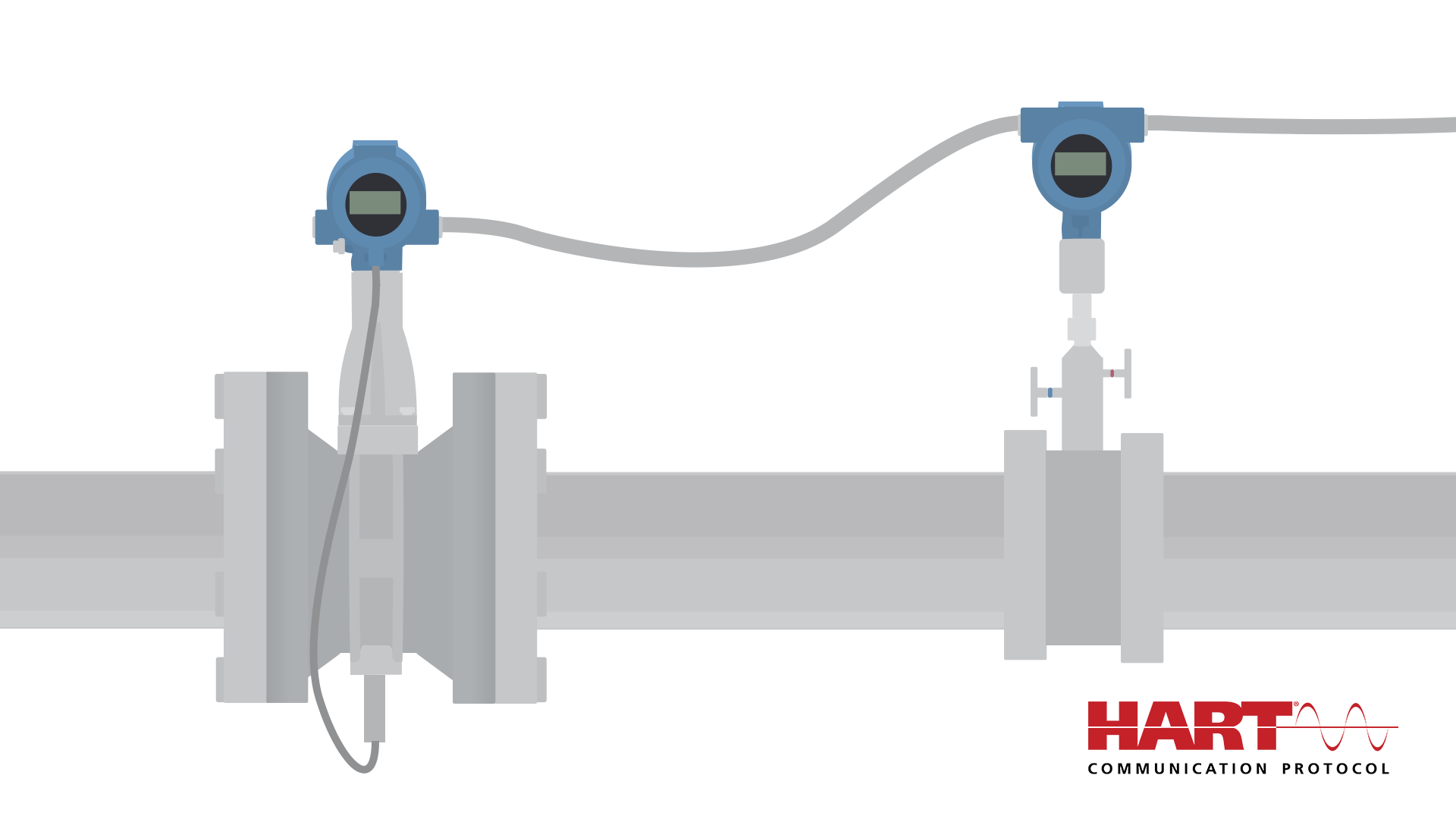

The 8800 MultiVariable utilizes a simple mechanism in the HART® protocol called Catch Device Variable to retrieve a digital HART® protocol signal from a HART pressure device that is on the same HART® network.

The 8800 MultiVariable retrieves a pressure value from the pressure transmitter every one to three seconds, depending on other HART® communication protocol traffic. Then, the 8800 MultiVariable calculates compensated mass flow measurement. HART® information is available from both the flow meter and pressure transmitter devices even while the 8800 MultiVariable is utilizing Catch Device Variable.

Flexibility of Wiring Configurations

There are multiple options for the wiring of your 8800 MultiVariable Vortex flow meter and 3051S In-Line Pressure transmitter. A few simple questions will help you determine the right choice for your needs. If variable analog output is not required, you can use the fixed analog configuration. If variable analog output is required, you have two options for your wiring configuration – dual analog and single analog.

Straightforward Fixed Analog Configuration

The easiest approach for wiring these two transmitters together is through a fixed analog configuration. This configuration wires the devices in parallel and can be used when a variable analog output is not required from either device. A HART® communication bridge is not necessary with this configuration but can still be used.

A Solution for Variable Analog Output

Many installations require each transmitter to use separate current loops to enable analog signaling in the 4-20 mA range. For mass compensated flow measurement based on measured pressure, the 8800 MultiVariable needs to receive this information via coupled HART® communication, which isn’t available with separate current loops. The HART® Communication Bridge is a compact DIN rail or wall mountable device that provides coupled wired digital HART® communication signals between devices on isolated analog current loop circuits with the ability to easily disconnect when needed.

Dual Analog Wiring Configuration

This option connects both transmitters to the communication bridge. Dual analog provides the capability for the vortex meter to receive the pressure input from a HART® pressure transmitter while maintaining the ability for independent 4-20 mA outputs from the pressure transmitter and the vortex meter. The two transmitters exchange data locally, so the two 4-20 mA analog signals can be interpreted by the host system independently.

Single Analog Wiring Configuration

This option only requires one 4-20 mA analog signal. It provides the capability for the vortex meter to receive the pressure input from a HART® pressure transmitter while maintaining the availability of the 4-20 mA output from one of the devices. Individual secondary measurements like pressure and temperature are available via the HART® signal when the HART®-enabled I/O is in use. This is a good option for applications when I/O slots are at a premium.

Multivariable flow meters are an excellent choice for when you need high accuracy in an integrated, cost-effective device. By combining our vortex technology with an integrated temperature sensor and connecting it with our Rosemount 3051 In-Line Pressure transmitter, we’ve developed a peerless multivariable solution for even the most daunting steam and liquid applications. Learn more about solving your steam flow measurement challenges by downloading our white paper on advanced vortex flow metering technologies, containing all of the wiring configuration diagrams and illustrations discussed above. Download white paper now.