Control architectures can play a key role in bridging the Operational Technology (OT) and Information Technology (IT) systems required for advancing digital transformation initiatives.

Control architectures can play a key role in bridging the Operational Technology (OT) and Information Technology (IT) systems required for advancing digital transformation initiatives.

In the fourth Design World article in a series on Big Data, Edge controllers bridge OT and IT systems, Emerson’s Derek Thomas explores “how results produced by edge controllers can be securely transmitted to a variety of other systems using built-in secure communication capabilities.” The first three articles include: A little data approach to solving big data problems, Little vs. big data, and Edge processing enables improved operations.

In this final article in the series, Derek highlights the role of edge controllers.

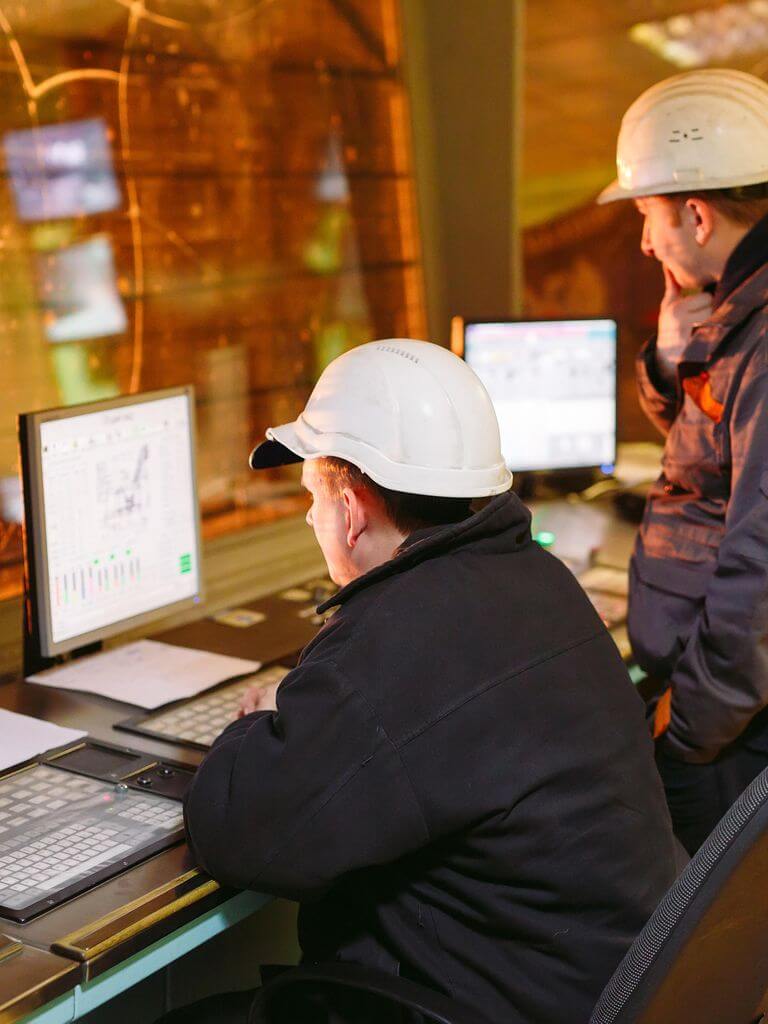

Edge controllers integrate advanced computing and software capabilities to deliver local analytics and generate insights right at the machine control layer. By augmenting machine operation with advanced capture and processing of local sensor and device outputs, personnel close to the source can quickly assess issues and take appropriate action.

Secure communications are required for enabling:

- Connection to local or remote displays for dashboards and other visualization needs

- Transfer of pre-processed data to on-premise or cloud-based historians and databases

- Integration of analytics information with plant- or enterprise-level systems

- Inner-outer loop data interchanges for logic optimization and machine learning

In earlier articles in the series, he explained that:

…the most advanced industrial edge controllers have separate, virtualized operating systems (OSs) which run independently, but can securely communicating with each other via OPC UA.

Derek explains the purpose of the separate operating systems.

One OS is a programmable logic controller providing real-time deterministic control, and another OS provides Linux-based, open, high-performance computing for analytics and other applications. To guarantee machine performance is unimpeded, edge controllers have dedicated communication ports for each OS, which ensures separation of network traffic between the machine network and higher-level industrial internet of things (IIoT) connections. The real-time part of the edge controller works best for time-sensitive communications, for example to a variable frequency drive in a control loop. The Linux part of the edge controller works well for other types of communication, such as with higher-level computing systems and the cloud.

Read the article as he highlights the wide variety of industrial networking, IIoT and other advanced protocols that advanced edge controllers support including OPC UA, MQTT, PROFINET, and SRTP.

Visit the Edge Control section on Emerson.com for more on the technologies and solutions to integrate a data-driven feedback loop into your operations for improved process performance. You can also connect and interact with other edge computing experts in the PLC, PAC Systems & Industrial Computing Forum in the Emerson Exchange 365 community.