We rely on uninterruptible power supplies (UPSs) for many of the important electronic devices in our home. They are also often used in discrete and hybrid manufacturing operations for machinery control.

In a Control Engineering article, How to keep machines operating during stoppages and power disruptions, Emerson’s Mike Johnson and Enrico De Carolis share how zoned safety and UPSs for control power to these machines enable control during stoppages and power disruptions.

They open describing safety risks in many of today’s complex machines.

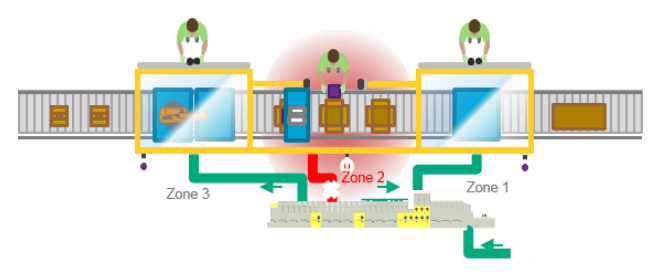

As packaging line machinery has become more sophisticated, it has also become more complex. This increased complexity, coupled with a high number of interactions between operators and machines, increases the potential for safety incidents.

For example, in the packaging world, production lines may stop for manual loading 10 to 30 times per shift, each time necessitating some form of interaction that exposes operators to possible risk and increases the potential for a safety incident.

To address these challenges:

…innovative technologies such as zoned safety and uninterruptible control power solutions offer enhanced control of machines during stoppages and power disruptions. Providing operators with enhanced functional safety systems on their machinery helps minimize the impact of these events on operations and results in more predictable machines that improve operator safety.

The tradition approach to machine safety ensures:

…operator safety of these machines has required employing discrete safety circuits with redundant dump valves, designed for lockout/tagout (LO/TO) applications, that shut off air supply, dump air and disable machine operation.

In addition to wasting energy by repeatedly dumping all the compressed air in the whole machine and forcing operators to wait for extended periods as entire systems restart, this approach adds significant complexity and unnecessary cost to the machine design because it requires complicated control structures to be in place and more expensive components.

With zoned safety technology, which meets the requirements of the Machinery Directive and ISO 13849-1, it:

With zoned safety technology, which meets the requirements of the Machinery Directive and ISO 13849-1, it:

…simplifies the design of a redundant pneumatic safety circuit with a single manifold system that can be configured to shut down air and power to only the group of valves that controls the machine’s specific motion in the operator’s vicinity while the rest of the machine remains in operation.

From a power disruption standpoint, these:

…can occur with little or no warning, and the sudden machine stops that result from these disruptions can be dangerous, time consuming and costly. In addition to potentially exposing operators on a packaging line to unsafe conditions, these stops can lead to damaged equipment, ruined product, material pileups and product backorders.

Uninterruptable power supplies, such as SolaHD SDU Series DIN Rail DC UPS Systems can keep critical , electronics-based control equipment such as field power supplies, programmable logic controllers (PLCs) and communications devices running during these periods of power disruption.

Read the article for more on zoned safety and industrial UPSs to maintain safe, efficient and productive manufacturing operations. Visit the Machine Safety and Power Protection sections on Emerson.com for more on these technologies and solutions.