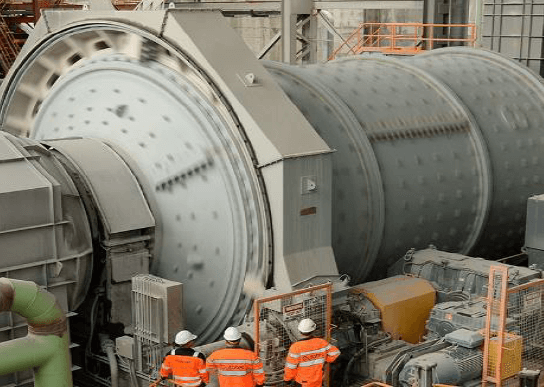

In mining operations, the comminution process reduces the mined solid materials through crushing, grinding and other means. SAG and Ball mills are one of the most critical pieces of equipment for the process. Mining operators need to optimize grinding mill performance, and reliability to ensure tight shutoff.

In mining operations, the comminution process reduces the mined solid materials through crushing, grinding and other means. SAG and Ball mills are one of the most critical pieces of equipment for the process. Mining operators need to optimize grinding mill performance, and reliability to ensure tight shutoff.

This process equipment can have unexpected shutdowns and production loss, high reprocessing rates, high operating costs, risks to personnel and the environment, varying loads placed on it, and pump failures.

To address these challenges, predictive maintenance practices can be instituted which include reliable and accurate measurements and control valves, process modeling and simulation, advanced control applications, online diagnostics, and operational analytics to provide early alerts on potential failures.

For example, smart wireless sensors enable online monitoring of critical equipment and help to avoid costly plant shutdowns and purpose-engineered slurry isolation valves extend reliability and operational life.

These continuous monitoring technologies support more effective and efficient work practices and help prevent failures which can lead to costly plant shutdowns. They also enable efficient reporting, continuous improvements and minimization of major plant upsets.

Mill circuit isolation is another area challenged with maintaining optimized grinding mill performance and reliability to ensure a tight shutoff. Excessive valve wear and equipment failures lead to increased planned and unplanned shutdowns. The Clarkson KGA+ automated slurry knife gate valve provides full port flow with tight shutoff. The valve sleeve design ensures jam free operation when changing from the duty to standby pump and connects to pump shutdown to minimize time to valve closure.

Remote valve automation is a key requirement in many mining operations. With electric power often not readily available, solar powered valves and actuators can be the optimum solution. Keystone valves and Bettis actuators can help achieve an efficient, environmentally friendly and economical solution, avoiding the potential for significant environmental harm and saving the cost of installing mains power to the water fill station. Automating a manual water fill operation helps to reduce water waste by avoiding overfill conditions.

Visit the Crushing and Grinding sections on the Emerson Mining, Minerals & Metals page for more on the technologies and solutions that can drive greater reliability, performance and safety in your mining operations.