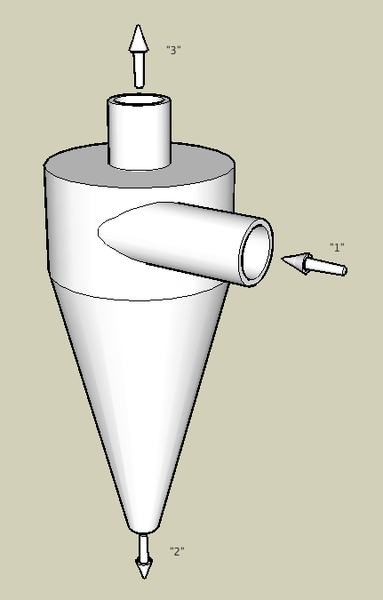

Diagram of a hydrocyclone:

1. the liquid-solid mixture enters,

2. heavy solids leave,

3. cleaned liquid leaves.

Photo credit: “hydrocyclone” by VanBuren is licensed under CC BY 3.0

In the mining industry, hydrocyclones are mineral processing equipment used in slurry pulps to separate coarse and fine particles according to their size and density. From Wikipedia:

The mixture [slurry pulp] is injected into the hydrocyclone in such a way as to create the vortex and, depending upon the relative densities of the two phases, the centrifugal acceleration will cause the dispersed phase to move away from or towards the central core of the vortex.

Coarse particles exit the bottom of the device (underflow) while fine particles are carried by the central air column and exit at the top (overflow). In metal processing applications, the product stream is the overflow (fine particles) and is typically sent to flotation circuits. The product stream is the underflow (coarse particles), as fines are separated from the final product as a means of quality control.

While under certain conditions roping and plugging can occur where the hydrocyclones ceases to classify the particles, the shapes of the discharge are visibly different than normal operating conditions.

The roping condition occurs when the amount of solids in the underflow increases to such a point that its discharge velocity is limited, resulting in the accumulation of coarse solids in the separation chamber. This mass passes through the vortex, causing the inner air core to collapse and the discharge at the apex to take the form of a solid stream (rope) consisting of coarse material with high solids density. Roping conditions reduce recovery rates and efficiency in metals processing and lead to quality losses in copper processing.

If not corrected in time the flow may clog and stop—a plugging condition which can result in contamination and downstream processing efficiency losses. Plugging occurs when the bottom aperture completely plugs forcing the materials overhead. In metals processing applications plugging reduces recovery efficiency, can cause flotation cell damage, and reduces overall availability—in order to clean the flotation cells.

To avoid these conditions and operate productively and reliably, Emerson mining controls experts developed hydrocyclone optimizer technology. This control and optimization application addresses the problems associated with roping, plugging, and undesired particle classification. It characterizes the different operating parameters of each cyclone. Having this information per cyclone allows the execution of efficient control strategies.

When the information is only per battery, you are not able to see which are the poor-performing cyclones in a battery. It is based on particle size distribution, mass flows, and densities of solids in the pulps transferred by the vortex and apex, in addition to their circulating loads. The application displays this information to the plant operator in real time.

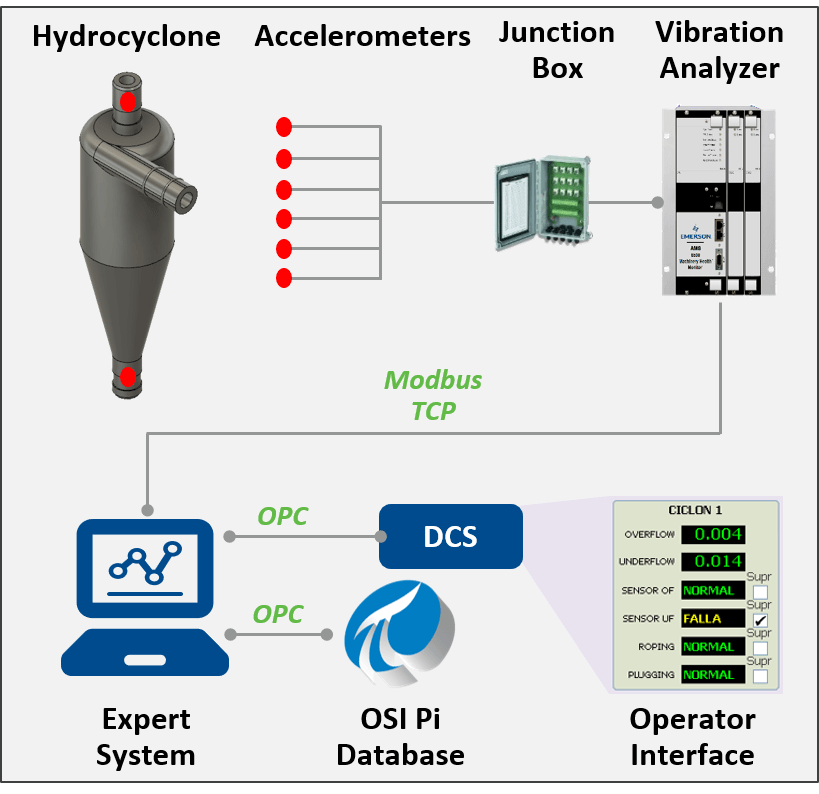

The solution uses two non-invasive, externally-mounted vibration sensors on each cyclone of a classification battery with the wired sensors placed in the vortex and apex areas and transmit the energy signals generated by the process. These vibration signals are processed first in a multi-channel Emerson AMS 6500 machinery health monitor and then in an expert system that resides either in a DeltaV Ethernet I/O card (EIOC) or a DeltaV PK Controller where roping and plugging conditions can be accurately identified.

The solution uses two non-invasive, externally-mounted vibration sensors on each cyclone of a classification battery with the wired sensors placed in the vortex and apex areas and transmit the energy signals generated by the process. These vibration signals are processed first in a multi-channel Emerson AMS 6500 machinery health monitor and then in an expert system that resides either in a DeltaV Ethernet I/O card (EIOC) or a DeltaV PK Controller where roping and plugging conditions can be accurately identified.

In addition to the vibration characteristics, the expert system also incorporates key process variables from the plant’s PI historian (expert system also pull data out from plant existing PLC or DCS) and provides real-time particle size distribution data to the operator.

This solution helps reduce process downtime, increase recovery, avoid quality penalties, improve production efficiency, and lower operations costs by providing early recognition of misclassification conditions.

Visit the Mining, Minerals & Metals section on Emerson.com or share your contact information to connect with an expert. You can also connect and interact with other mining industry experts in the Metals & Mining group in the Emerson Exchange 365 community.