Reliability of assets used in the manufacturing process is paramount for safe, efficient and effective operations. Unplanned asset failures, improper asset performance, poor maintenance planning, and untimely follow-through can cause shutdowns, under-utilized production equipment, deviations, or material/product losses.

I caught up with Emerson’s Ben Arriola on how this applies to operational integrity for pharmaceutical and biotech manufacturers. Ben noted that from an asset performance perspective, equipment wear, minimal visibility of equipment performance and inconsistent equipment maintenance can result in decreased production, higher energy costs and larger repair costs.

One way to tackle these challenges is to use pH and pressure with the highest stability (low drift) performance, especially for the measurements used with Critical Process Parameters (CPPs). These sensors enable the control systems to provide greater control of CPPs, improve feedback and feed-forward control, and reduce sensor recalibration time and effort. These CPPs are often found in fermentation and buffer & media processing areas.

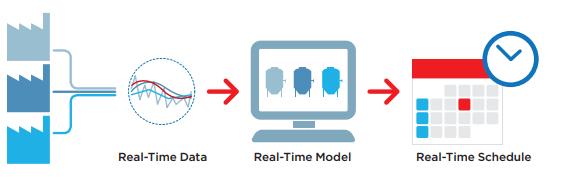

Unexpected equipment failures and breakdowns greatly impact production yield and facility throughput. This surprise downtime can be mitigated through predictive maintenance and planning, improved decisions based on collected actionable data, and continuous monitoring of rotating assets. Planning equipment maintenance while in full production takes significant time and effort, and often requires rework based on production schedule changes. Emerson’s Real-Time Modeling System enables order execution and equipment use models to identify and adjust maintenance plans based on the current production schedule.

To improve decision-making with a common robust repository, the AMS Trex device communicator provides a portable, durable connected devices to collect asset health data. This data is accountable, standardized, actionable, scheduled and secure.

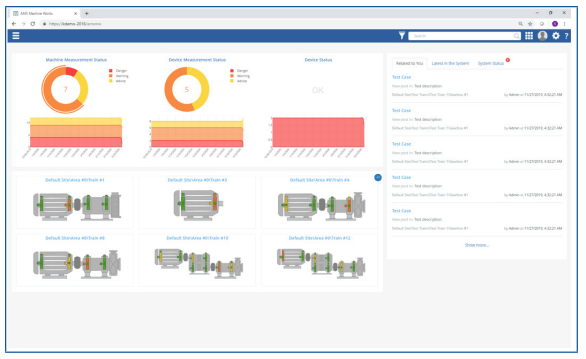

For rotating assets, early detection of developing issues can help to avoid costly slowdowns and shutdowns. Combining wireless or wired continuous vibration monitoring with operational analytics and dashboard visualizations enables the detection or prediction of impending abnormal conditions before they worsen. These predictive technologies include AMS Asset Monitor Edge Analytics, AMS Machinery Manager and AMS Machine Works Vibration Analysis software, and AMS Wireless Vibration Monitors.

Ben also shared that challenges around line or unit performance includes equipment that doesn’t perform per specification compromises line performance, introduces quality concerns and impedes production. Scattered PLC-based controls in environmental monitoring systems and others areas can be managed by the Movicon SCADA application. This approach enables alarming, data historization, and data analysis to improve supervisory and plant operations.

From a visibility and detection perspective, paper-based, manual data collection processes make it difficult to ensure proper equipment status, appropriate performance and prompt problem diagnosis. Combining stable, reliable measurements with Syncade equipment management software provides full visibility of the state of the equipment across the facility. This visibility enables equipment state management to ensure the use of properly cleaned and sterilized equipment in the production process. This helps eliminate equipment rework errors and ensure the proper equipment is used at the correct time during production runs.

Visit the Life Sciences & Medical section on Emerson.com for more on the technologies and solutions to improve equipment reliability for pharmaceutical and biopharmaceutical manufacturers.