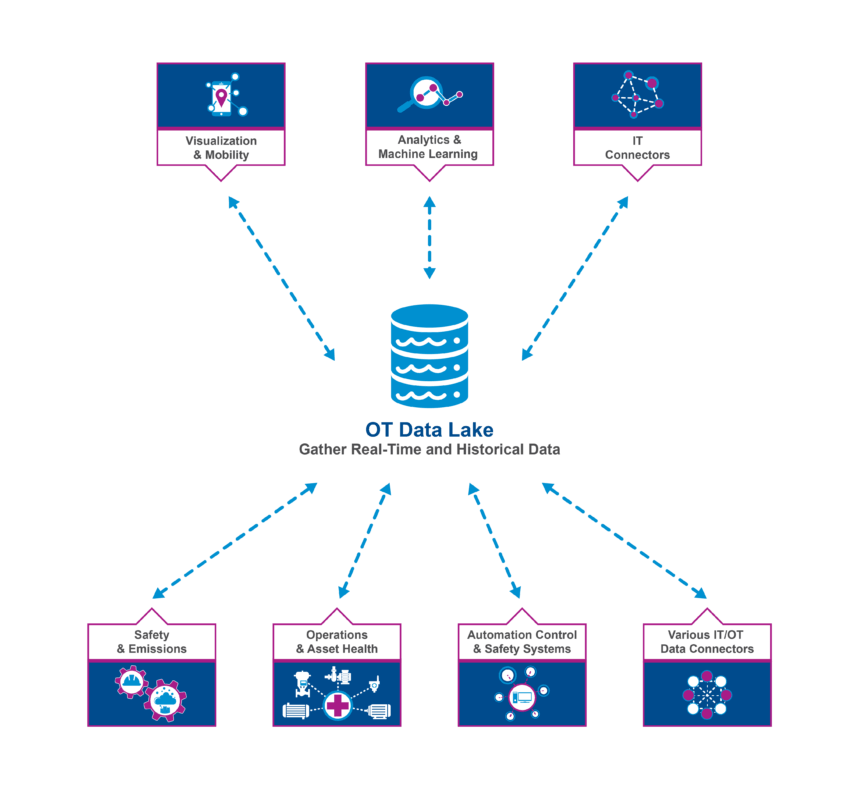

Digital transformation is prompting many organizations to reexamine the way they handle data across the enterprise. A common challenge many organizations face is siloed data. Over the years, as new equipment, processes, and even facilities were added, plants adopted a wide range of technologies. As digital transformation teams begin to gather data from those disparate technologies, OT and IT run the risk of building overly complex solutions to enable transfer of data to digital tools such as cloud analytics software.

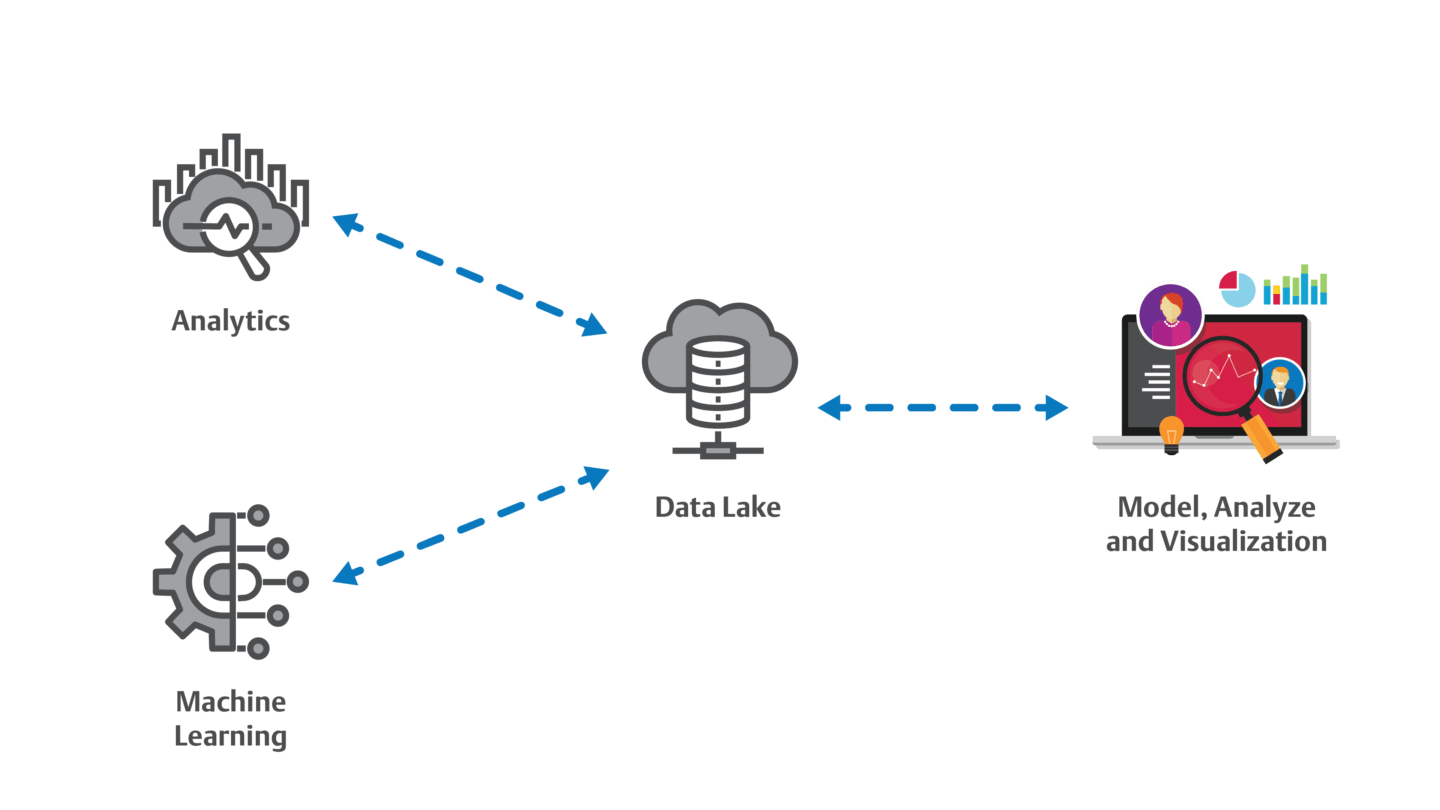

Vineesh Kapoor, director of product management for Plantweb™ at Emerson recently spoke with Plant Services magazine about the many ways data lakes can reduce data complexity. Data lakes eliminate the data silos restricting visibility and impeding digital transformation across the enterprise by centralizing, standardizing, and contextualizing data from a wide variety of disparate systems. Vineesh offers strategies to select and implement the best data lake for an organization’s unique needs.

Comprehensive connectivity

Most organizations are running a wide variety of new and legacy equipment across their plants. When they try to connect these systems, they need solutions for connecting to various integration frameworks—solutions that are not always readily available.

Engineering, reliability, maintenance, operations, research, and other departments may all need to collect OT data from each other. Due to variation, delivering this collaboration often requires many connectivity software packages for security, buffering, tunneling, bridging, and redundancy management. This frequently results in a complex, difficult to maintain connectivity patchwork.

Even when organizations identify a complex architecture to connect to legacy systems, they don’t always easily connect to emerging technologies like cloud analytics. In fact, when they don’t work properly, the impact can be quite serious,

In the most severe instances, these solutions can exceed the capabilities of the OT systems’ infrastructure, causing occasional outages.

The key benefit to using data lakes in this situation is they can act as data translators, avoiding the need to rip and replace legacy systems for better visibility. Modern data lake systems offer,

a wide range of out-of-the-box connectivity solutions enabling connection to nearly any system OT might use.

No data left behind

Traditionally, plants rely on the data historian to record critical plant data. Unfortunately, however, that “history” is limited. Most historians are not equipped to store the wide variety of data plants now rely on to run at their best.

The historian is typically most effective in collecting and storing numerical data. While this is valuable for some functional areas, it leaves out many of the data types functional groups rely upon such as photos, videos, spreadsheets, and more.

A data lake can store nearly any type of data a plant or its personnel generate. Users can find any piece of information they seek, all in one application, increasing efficiency and enhancing security by reducing the use of removeable media. Data lakes can also connect

…directly to computerized maintenance management systems (CMMS) to close the loop on maintenance.

More meaningful data

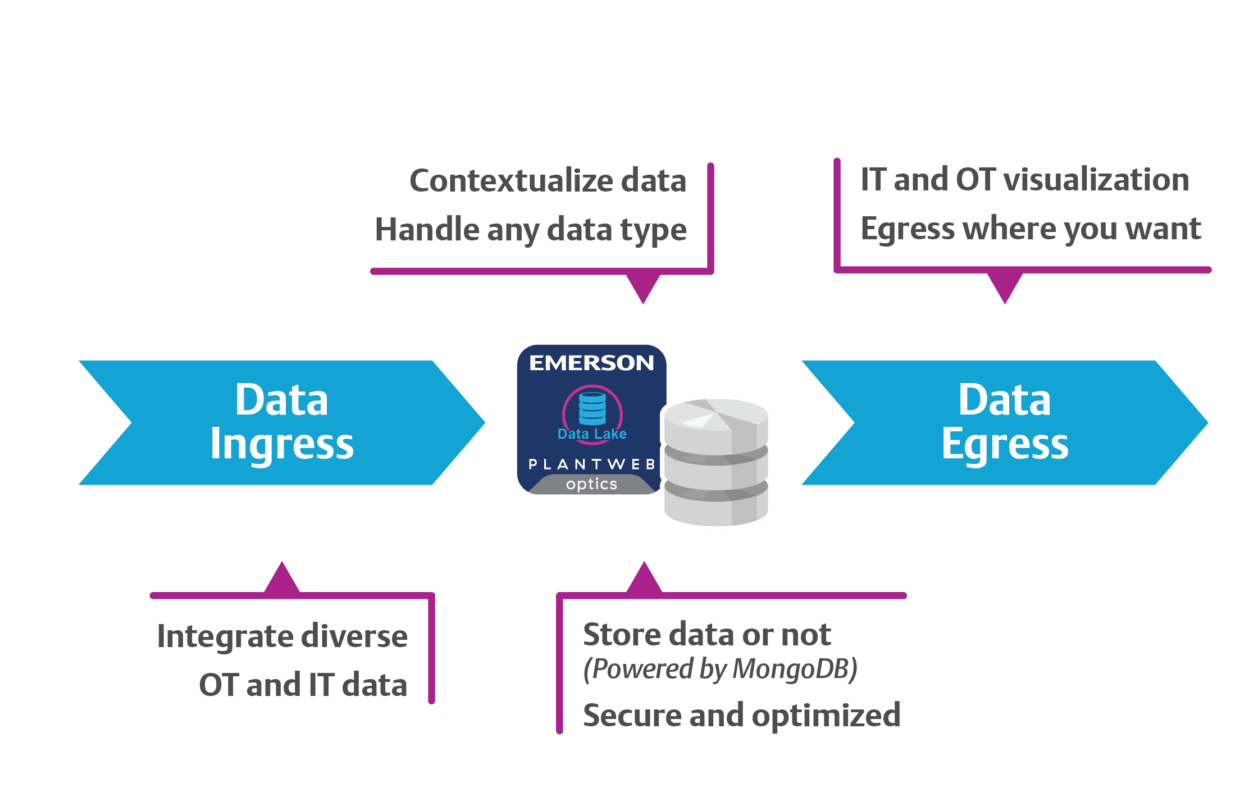

The best data lakes automatically collect data in one location and standardize it, to make it system agnostic. Emerson’s Plantweb Optics Data Lake automatically translates a wide array of data points into uniform data that can be sent to almost any tool the organization may employ across the enterprise. Plantweb Optics Data Lake enables

users from many different functional areas to run and view reports on cross-enterprise data from wherever they are. From their desk or from the field, users can track and trend performance to confirm proper configuration, evaluate performance based on equipment manufacturer operating conditions, and more.

To learn more strategies for selecting the data lake technology that is best for your organization, read the article in its entirety at Plant Services. You can also visit Emerson Exchange 365 to share digital transformation thoughts and strategies with other industry experts.