Many professionals working in manufacturing plants are confronted with obstacles every day caused by outdated instrumentation technologies and practices, which can hinder operational efficiency. Fortunately, advanced pressure and temperature instrumentation can optimize plant performance and enhance safety through improved preventative maintenance, installation cost savings, increased measurement accuracy, and actionable insights for more informed process decisions.

This new white paper focuses on the challenges of outdated technologies and practices – which often lead to process upsets or safety risks – and outlines how the use of innovative pressure and temperature instruments can overcome these common, yet often hidden measurement issues. Although the causes and effects of the following obstacles are different, all can be mitigated or eliminated entirely through the use of advanced pressure and temperature technologies.

Find solutions to these six common issues:

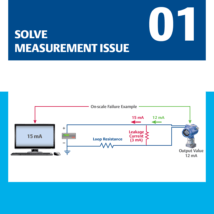

Measurement degradation due to deteriorating instrument wiring: Electrical current leakage, often due to moisture or corrosion, as well as an increased electrical load from a failing or overtaxed power supply are two common causes of measurement degradation. Advanced pressure transmitters are available with loop integrity diagnostics which monitor the available voltage on a continuous basis to detect and correct these issues before they jeopardize your operations.

Heat tracing headaches: Heat tracing is a costly and maintenance-intensive solution with a poor track record for reliability. Electronic Remote Sensor (ERS) Systems solve these headaches by eliminating the need for impulse piping and heat tracing entirely. With no electricity or steam required for heat tracing, ongoing saving of operating and maintenance costs are also possible.

Impulse lines and process connection issues: Conventional impulse lines can create a variety of problems that range from freezing in cold weather to leakage, which can lead to potential safety, economic, and environmental implications. Today’s advanced transmitters are able to perform a plugged impulse line diagnostic to proactively detect these issues before they impact production.

Mechanical Bourdon tube pressure gauge challenges: Typical gauge failures include broken glass, bent indicator needles, or in some cases the Bourdon tube may even rupture, resulting in a leak point that can expose personnel to hazardous process fluids. Wireless Pressure Gauges use a solid-state sensor and process the signal electronically, rather than mechanically, making them far more reliable and resistant to shocks, vibration, and other extreme operating conditions.

Reducing thermowell safety risks: Thermowell design can be an arduous process, requiring engineers to make a number of critical evaluations and perform time-consuming manual calculations. New digital tools streamline this process by automatically optimizing thermowell design and reducing design time by more than 90%, resulting in the most safe, reliable, and accurate temperature measurement for your application.

Temperature sensor degradation and failure: Many temperature measurement applications suffer from electrical noise, spiking, and signal dropouts. Other problems can be caused by wiring problems, mechanical shock, or vibration. These issues can be detected, diagnosed, and possibly even corrected by sophisticated temperature transmitters.

Older technologies and practices can become obstacles to effective operation, but advanced pressure and temperature instrumentation provides solutions. Learn more by downloading the new white paper now.