The hybrid and discrete manufacturing industries often contain packaging lines for the finished products. Some of this machinery has been in operation for a very long time and does not include modern sensors, controls and analytics to make it run as safely, reliably and efficiently as possible.

The hybrid and discrete manufacturing industries often contain packaging lines for the finished products. Some of this machinery has been in operation for a very long time and does not include modern sensors, controls and analytics to make it run as safely, reliably and efficiently as possible.

A Packaging World article, Controls Upgrade Boosts Bagging, recaps a presentation by Emerson’s Chris Noble on how sophisticated controls can be added to legacy packaging machinery. At the last PACK EXPO conference, Chris demonstrated:

…a 15-year-old bagger used to produce, for example, 75-lb bags of corn kernels or soy beans. The machine takes flat, empty sewn-open-mouth bags from a magazine feed, positions them beneath a funnel, and discharges soy beans, let’s say, through the funnel and into the bag before sewing the bags shut and discharging them.

The article’s author describes to old way this bagger operated:

The pneumatic actuator responsible for opening and closing a gate valve releasing beans into the funnel was originally capable of just two positions: full open or closed. When the bagger called for product, the gate valve would open and release product into the funnel, but it would do so in what might be called a “dumb” fashion.

This operational method resulted in filling inaccuracies and additional rework. Chris explained a better way.

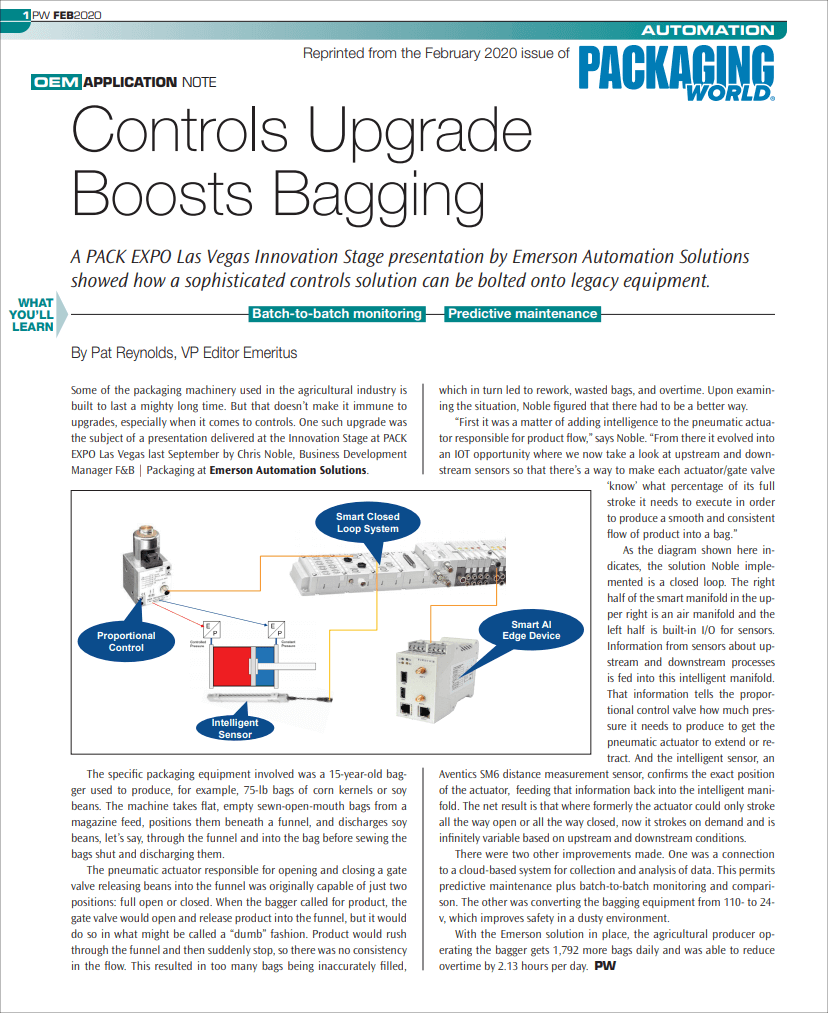

“First it was a matter of adding intelligence to the pneumatic actuator responsible for product flow… From there it evolved into an IOT opportunity where we now take a look at upstream and downstream sensors so that there’s a way to make each actuator/gate valve ‘know’ what percentage of its full stroke it needs to execute in order to produce a smooth and consistent flow of product into a bag.”

Read the article for how these sensors, including an AVENTICS SM6 distance measurement sensor feed an intelligent manifold which controls a proportional control valve to tightly control the filling operation within the specification limits.

Visit the Packaging section on Emerson.com for more on ways to improve control on legacy packaging equipment. You can also connect and interact with other packaging experts in the Fluid Control & Pneumatics group in the Emerson Exchange 365 community.