Author: Pete Sharpe

An ethylene plant has a number of very large, very critical compressors which will cause the entire plant to shutdown if they ever trip. The cracked gas compressor increases the entire cold-side feed from around 3 psig to ~475 psig, typically through 5 stages. The two refrigeration compressors are the next biggest compressors that can also shut down the entire plant if they trip.

Anyone who has been around an ethylene plant when it trips knows that it creates a huge flame the whole community can see and hear when the entire inventory of the plant vents to the flare. Besides these critical compressors, there are several smaller compressors that can also impact operations. Most sites are pushing major turnarounds from 5 to 7 years, so online monitoring of the health and performance of these compressors is important to achieve those goals.

All of these centrifugal compressors will have an anti-surge system and turbine speed controls, as we’ve highlighted in earlier compressor surge posts. One major surge event can not only shut down the plant, but do major damage to the compressor and take weeks to repair and cost a lot of money. Many of these compressor will have legacy surge control systems that are usually in a separate PLC supplied by the compressor vendor or a 3rd party, and are difficult to troubleshoot and maintain. Third party service personnel must be flown in, costing additional time and money. Lots of these systems were put in when the plant was built and have not been changed since. Some systems are no longer supported by the supplier.

Furthermore, legacy systems have direct I/O to the field and often the operators have limited or no visibility to any of the inputs or surge calculations on their distributed control system (DCS) console. Typically a separate monitor is supplied by the surge control supplier for interacting with their application. Integrating the compressor control with the process control functions can be done, but requires interfaces and significant effort.

Finally, it is true that the surge cycle is a fast phenomenon that can occur in less than a 500 millisecond frequency. Anti-surge systems predict when surge will occur and open the recycle valves in advance to prevent it. So a fast control cycle (<200ms from sensor to valve movement) is typically specified for this application. That said, in fact, the dynamics of the compressor system determine the required control cycle time.

Most compressor systems have sufficient volume in the suction drums and pipelines to dampen the pressure swings when supply or demand of the gas changes quickly, giving the surge control system time to respond. The other side of big volumes around compressors is that it slows the flow reaction to the recycle valve movement, which sometimes can take over a second. Process measurements matter too. The flow sensor is noisy by nature, so a 1st order input filter with the time constant of 150ms and higher is used to suppress noise. Furthermore, the slowest component of the control system will be the recycle control valve. If the valve has any hysteresis or it sticks or takes a half second to move, sending signals to it every 100ms does not help. To make sure the machine is protected, many times the anti-surge system is set up conservatively (e.g. the recycle valve opens before it really needs to). This practice wastes energy.

The compressor anti-surge value improvement practice takes advantage of modern DCS tools and specially designed Fisher valves for anti-surge control. The latest DeltaV PK controller from Emerson has a 100ms processing speed, sufficient for most anti-surge systems. It is totally integrated with the DeltaV control system and uses the same configuration tools and user interface as other DeltaV controllers. A pre-engineered SmartProcess Compressor control library provides standard templates for building compressor control applications, graphics, interlocks, alarms and sequence logic. A load balancing algorithm balances multiple parallel or series compressors to keep all recycle valves at their minimum position, preferably closed. The system uses standard DeltaV functions so can be maintained by local DCS staff.

Note that for machines which already have a Compressor Control Corp (CCC) anti-surge system and replacement with PK controller is not desirable, Emerson can also provide a standard DeltaV CCC Smart Gateway to link the CCC system into DeltaV for operator display and control purposes. This application provides console operators with the ability to view the CCC information and operate the compressor from the DeltaV console.

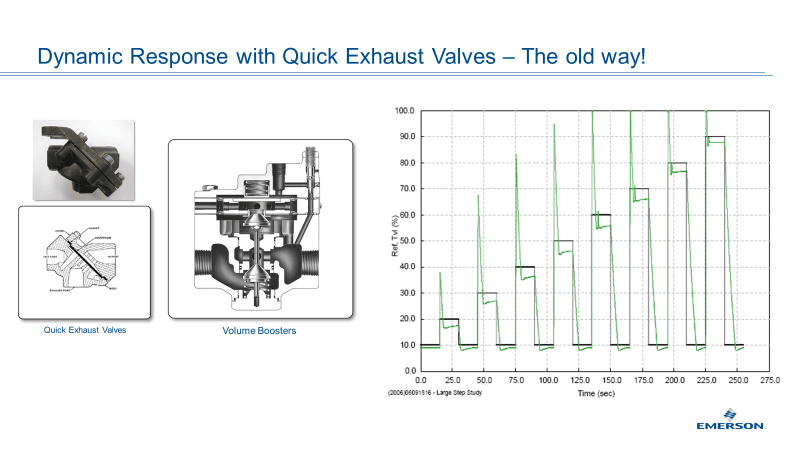

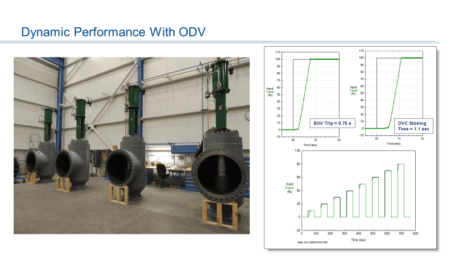

Since the recycle valve response is a critical component of loop speed, Emerson has designed ultra-high-speed Fisher valves specifically for surge control purposes. Past solutions involved adding an air volume booster and quick-exhaust valve, which created significant overshoot. The Fisher Optimized Antisurge Control Valves deliver high-speed response and precision. See before and after comparisons below. Precision, high-speed control valves allow the system to operate safely closer to the surge point, thus saving energy from reduced gas recycle.

This value improvement practice creates value by removing a “black box” from the compressor control architecture. Compressor field sensors can be brought into the DCS along with their HART diagnostics. Operator graphics and control functions can be integrated into a single environment, not kept separate. Local staff can more quickly and easily troubleshoot and correct issues. Emerson’s proven compressor anti-surge application helps you achieve safer operation with zero surge events. In the past 18 months, the Emerson anti-surge application has been installed on compressors with more than 51,000 operating hours without incident.

In the next series of blog posts, I will cover some of the other key value improvement practices for ethylene complexes to improve production, reliability, safety, energy and emissions.

From Jim: Visit the Operational Certainty and Downstream Hydrocarbons sections on Emerson.com for more on the technologies, methodologies and solutions to help you drive business performance improvements.