In an earlier post, Optimizing Food and Beverage Machinery Performance, we shared how sensors combined with advanced analytics could keep packaging lines operating more safely, reliably and efficiently.

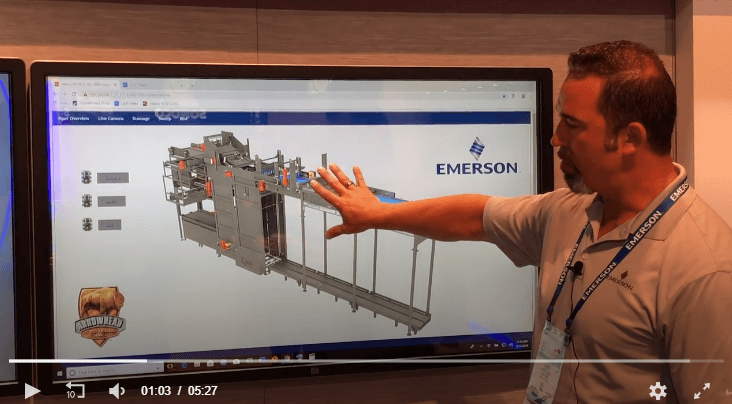

In this post, Emerson’s Chris Noble gives a demonstration of packaging equipment monitoring. The video is posted on the Packaging World site in a post, Emerson and Busse/SJI Collaborate on Palletizer Health App.

In this 5:27 video, Chris is introduced by Emerson’s Marcus Parsons and begins the demonstration around the one-minute mark.

Chris describes the overview screen in the application highlighting each of the sections of this can palletizer system. The application is monitoring the health of the assets on this palletizer machine. Some assets include on the sweep in the bed area which has a motor and bearing assembly that provides air to help the cans move forward.

The goal of this monitoring is to improve overall throughput and get early indications of any developing issues. He shows the main control center indicating the overall flow through the sweep area, overall pressure and overall vacuum. All the air cylinders are being monitored. Green, yellow and red statuses are provided on the monitored components.

By touching the screen, the user can drill into the component in more detail to assess the situation. Connections with Enterprise Resource Planning (ERP) systems enable replacement parts to be quickly found and replaced during the next available maintenance window.

Chris also shows how wireless devices, such as a wireless vibration transmitters, monitor the motor and bearings. Watch the video for more on how this monitoring helps improve overall operational performance.

Visit the Packing & Palletizing section on Emerson.com for more on the technologies and solutions to improve business performance. You can also connect and interact with other packaging experts in the Fluid Control & Pneumatics group in the Emerson Exchange 365 community.