Emerson’s 2020 Ovation™ Users’ Group Conference opened with Bob Yeager, president of power & water solutions, providing an update on the power and water landscape in our rapidly changing world. Bob opened with a look at how interaction and routines have drastically shifted in ways beyond our control, both in life and in business.

One of the primary ways this change has manifested has been through a shift toward digital solutions as a requirement to maintain operations. Bob outlined how a move toward more virtual factory acceptance tests (FATs) has helped organizations maintain project schedules and continue improving performance. In the last six months, nearly all FATs have been performed virtually.

We’ve been doing virtual FATs for a long time. But now, since nobody can come in the building, everything has been a virtual FAT, and it has gone extremely well. We’ve maintained schedules, on-time delivery, and fantastic performance.

Digital transformation has been at the heart of a successful move to efficient operating strategy—particularly in the era of COVID-19. This has meant changes in the way plants operate and the way they approach projects.

Emerson’s Stuart Harris, president of digital transformation, spoke about the profound impact of digital transformation across the power and water industry. Stuart explained how Emerson’s digital transformation business helps customers develop and execute strategies to increase operations flexibility, helping them confidently achieve business goals. He shared:

A typical power plant spends 40 or more person-hours per day on manual inspection of hundreds of measurement points. Using wireless technologies, 70% of those measurements could easily be automated with a payback of under one year.

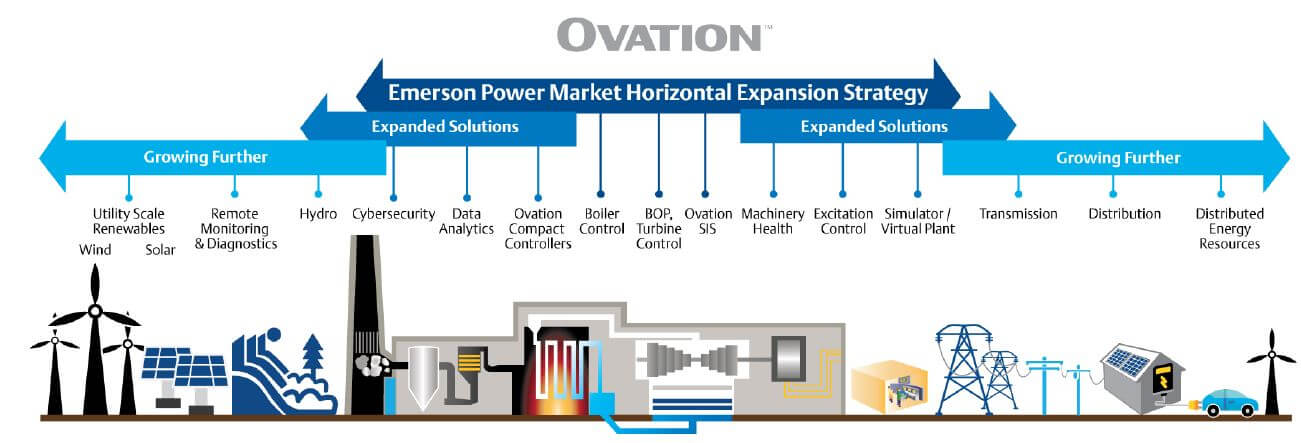

Bob added to Stuart’s digital transformation message, describing how the Ovation platform has evolved well beyond the bounds of traditional distributed control by adding native products and solutions that help transform operations.

We are not just a DCS company anymore. We are also an excitation, a condition monitoring, a simulation, a cybersecurity, a visualization, a PLC, and a data analytics company.

Emerson digital twins are active across the globe creating high-fidelity simulations allowing power companies to monitor, test, strategize, and analyze their solutions for continual growth and innovation.

Bob also explained how Emerson is using new strategies to help digitally transform the power grid from generation to meter.

It used to be that generators would generate electricity and it would flow through transmission to distribution to the home and that was it. Not so much anymore. The bidirectional flow of electricity is creating very complex environments, for net metering for example. It’s driving the need more than ever for end-to-end software from generation through transmission to the distribution to the home—and even inside the home.

Changing industry

Another significant area of change Bob highlighted is training. Because users can no longer sit shoulder to shoulder in a classroom but still need to learn and develop new skills, Emerson has quickly revamped its educational services, delivering a variety of new virtual formats to offer flexible instruction.

Bob shared a key piece of customer feedback that sums up the way Emerson and its customers have responded to COVID:

These procedures are innovative and smart. There is always a way. Human spirit is tough to beat!

Expansion in hydropower

Shifting gears, the discussion turned to current events in power and water, beginning with the news of Emerson’s acquisition of American Governor. American Governor’s founders Scott Ginesin and Dan Berrien joined Bob to share the history of the company and how its constant focus on supporting customers fits perfectly with Emerson’s leadership in hydropower.

Scott and Dan explained how combining the expertise of American Governor—parts, service, support and training—with the existing power and water expertise and Ovation control technology of Emerson will provide the tools any organization needs to make its hydroelectric equipment run more efficiently and effectively.

‘Unlimited Expertise 24×7’

Other news included collaboration with Mitsubishi Power—providing Emerson expertise and the Ovation distributed control system (DCS) to help create the most advanced gas turbines and combined cycle plants in the world. The MHPS-TOMONI™ plant uses digital transformation technologies to operate as though it were

a plant that can perform like it had an unlimited number of experts on site, 24×7, who can recommend and respond instantaneously.

This on-demand access to expert knowledge is the basis of digital transformation and is incorporated at the core of the Ovation platform with technologies such as artificial intelligence (AI), machine learning, and digital twin simulation.

Conference Continues Through Aug. 27

The Ovation Users’ Group Conference resumes August 19 and runs August 20, 25, 26, and 27. Topics include how to make digital transformation real and bringing the future of customer service to customers today. The latter three days will be in-depth, expert-led industry sessions focused on the power, water, and wastewater segments.