Springtime here in the Northern hemisphere means lots of industry and professional organization events. This week I’ve highlighted happenings from the pharmaceutical and biotech manufacturing industry at Interphex 2019.

Also going on this week is a gathering of Chemical Engineers at the 2019 AIChE Spring Meeting in New Orleans. Here, Emerson’s Meha Jha presented Emissions Reporting and Energy Management with Flow Measurements.

Meha opened the presentation highlighting the ever-increasing regulatory pressures on manufacturers and producers around emissions and waste. Meeting these environmental regulations requires a mix of technologies and changed work practices. Undergoing a digital transformation includes sensors to measure control and non-control measurements, analytics & expertise to evaluate this stream of real-time data, and decisions made by the right people to act to remain within compliance and continuously improve operations.

This See-Decide-Act cycle includes rich analytics such as modeling & domain expertise, machine learning, diverse data sets, and the wealth of storage and processing power available in cloud-based applications. Making the results of these analytics and expertise to form decisions available to the right person or people in time requires mobile-based tools and communications.

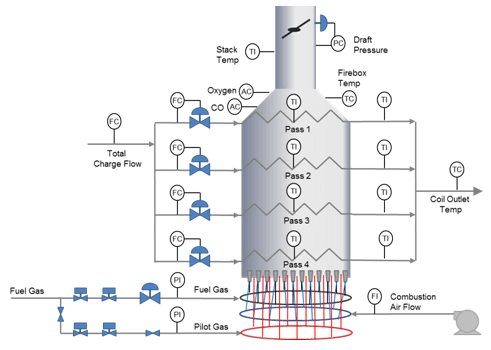

Meha shared an application of accurate and reliable flow measurement to meet environmental compliance and safety. The measurements are important for improving combustion control in fired heaters and boilers. The charge rates of the fuel gas stream is used in emissions reporting. Digital tools can help to improve compliance, avoid penalties, and fines associated with noncompliance.

Meha shared an application of accurate and reliable flow measurement to meet environmental compliance and safety. The measurements are important for improving combustion control in fired heaters and boilers. The charge rates of the fuel gas stream is used in emissions reporting. Digital tools can help to improve compliance, avoid penalties, and fines associated with noncompliance.

The two most common methods of combustion control of fuel gas include volumetric flow or pressure control. In these control strategies, the outlet temperature of the heater cascades and resets either a volumetric flow controller, or a pressure controller. Under steady operating conditions these two methods of control give adequate response and control of the heater. When there is a disturbance in the system though, especially caused by a change in the composition of the fuel supply, these control methods may be inadequate for the desired level of safety, fuel efficiency or environmental compliance.

High levels of O2 in the flue gas can lead to increased emissions and permitting issues. Running high levels of O2 in the flue gas also results in decreased energy efficiency, through heating excess air.

On the other hand, operating with too low a level of O2 in the flue gas creates the risk of sub-stoichiometric (insufficient oxygen) combustion, possibly tripping the heater, or in the extreme case, causing damage to the heater.

Sub-stoichiometric conditions can result when the composition of the fuel feeding the combustion suddenly changes to a richer fuel that is higher in heating value, requiring more oxygen. If this could be anticipated (i.e., feed-forward control), much of this challenge could be eliminated.

Reducing variability of the O2 in the flue gas is the primary means of being able to safely, lower the target O2 setpoint, and achieve the desired balance for safe, efficient environmentally friendly operation.

By using mass-based flow measurement—Coriolis meters—on fuel gas headers, the control loop can respond more quickly to changes in fuel composition. The traditional approach is to measure the process outlet temperature controller and/or the percentage of O2 trim controller to give feedback to the flow controller—both are lagging indicators and can be too slow to respond to fuel composition changes.

A design committee conducted a study that shows controlling on a mass basis reduces variability, improves safety, and can reduce emissions. By changing the control strategy to have the outlet temperature of the heater cascaded to mass flow control instead of volumetric flow or pressure control combustion stability can be maintained during these fuel composition changes.

Meha shared an example where a 121 MMBTU/hour crude charge heater with fuel gas containing varying compositions of methane (0-56%), hydrogen (17-72%), carbon dioxide (0-2%) and nitrogen (0-4.8%). A Monte Carlo based simulation tool that the committee asked Emerson to create estimated that switching from volumetric to mass-based flow measurement would reduce oxygen in the flue gas by 1.5% and result in a project net present value (NPV) of almost $450,000 USD.

Using Coriolis flow measurement technology improves fuel to air ratio control with changing composition, reduces oxygen in the flue gas by reducing excess air fed into the combustion process, reduces the probability of insufficient air and heater trips, optimizes the %Oxygen setpoints, and provide more accurate and reliable emissions reporting. Switching from traditional to mass-based fuel measurements typically results in $500,000 to $1,000,000 project NPVs.

Meha also noted that Micro Motion Coriolis flow meters have Smart Meter Verification to more easily and accurately report on fuel gas composition to regulatory agencies. Smart Meter verification allows the online verification, in-situ verification of the accuracy of the meter according to baseline factory standards.

Often times verifying the accuracy of the devices utilized to measure these flow rates can be inaccurate and difficult to verify the accuracy of the device because they involve having to pull meters offline and send to a flow lab to be verified and calibrated whereas with Smart Meter Verification, all of this verification can be done online, and since Coriolis technology is a direct mass measurement the accuracy of the device is very high and not impacted by changes in process conditions and density like other traditional flow technologies.

Visit the Micro Motion section on Emerson.com for more on Coriolis technology and how it can be applied in the this and many other applications. You can also connect and interact with other flow measurement experts in the Measurement Instrumentation group in the Emerson Exchange 365 community.