The growth in intelligent completions has surpassed all expectations over the last few years, with industry analysts such as Technavio predicting continued growth of as much as 5% year on year between now and 2023.

High profile examples around the world include the Al-Shaheen field offshore Qatar, where smart well technology is combining monitoring and control capabilities with multi-segment completions in order to optimize flooding mechanisms; the DIACS (Downhole Instrumentation And Control System) where permanent downhole pressure and temperature monitoring has been employed in individual zones to ensure better reservoir understanding, production optimization and increased possibilities for well diagnostics (Statoil (Equinor) Well Informed Magazine, June 2009); and Shell/BP’s deep water Na Kika field development in the Gulf of Mexico where intelligent completions have provided the ability to remotely monitor and control inflow from different zones.

Yet what are the essential elements of a truly intelligent completion? And is there anything still missing?

A truly intelligent completion involves understanding formation behavior, instigating the real-time zonal downhole monitoring of pressures and temperatures, and the remote monitoring and controlling of inflow from different zones. This involves more than the ability to access just a snapshot of flow contributions and requires accurate, multi-zone information from all areas of the well including the sandface – the physical interface between the formation and the wellbore, and the lower completion.

And all this must take place without the need for well intervention, such as production logging tools, that not only fail to paint a complete picture of pressure and temperature in the reservoir – due to the increase in complex horizontal laterals, for example – but also come with significant personnel, equipment and cost requirements.

So, are we there yet in terms of the complete intelligent completion?

Well, we’re a lot closer this week at the Offshore Technology Conference (OTC) in Houston with the first public unveiling of the Intelligent Multistage Completion Network™ (IMCN) featured in the daily newspaper – the OTC Daily (insert link).

The IMCN, developed by Emerson and Metrol, a leader in battery-powered wireless well monitoring, creates the first downhole reservoir network that connects wireless sandface data (an area previously considered off limits) to the upper completion. This gives operators unrivalled insights into the reservoir’s flow characteristics and – for the first time – a truly intelligent and integrated downhole monitoring system from upper to lower completion.

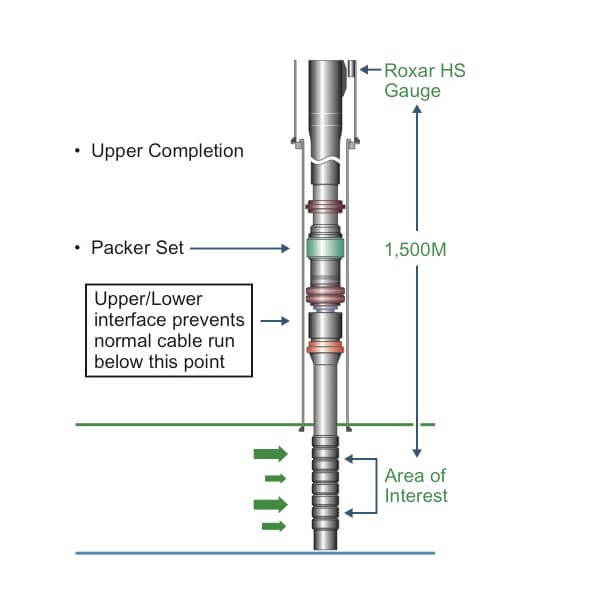

Whereas previously, downhole monitoring gauges (in this case the Roxar HS gauge) were set at a depth of around 4,000 meters but still 1,500 meters above the reservoir (see figure below), the IMCN provides unfettered access to instruments at the reservoir sandface via a new wireless interface that provides a bridge to Metrol’s wireless solutions.

In the words of Emerson’s article in the OTC Daily, “this means increased production and ultimate recovery elective zonal control, the pre-empting of production challenges, and reduced operating expenditures through fewer and more effective interventions.” A fully intelligent completion.

OTC has always provided a platform for new innovations in the oil & gas sector. With Emerson’s Intelligent Multistage Completion Network, OTC 2019 is no exception!

If you’re at the show this week, visit the Emerson at stand 2261 to find out more.