At the 2019 Ovation Users’ Group conference, Emerson’s Sam Onuska and Greg Lieb provided an update on turbine overspeed protection in Ovation distributed control systems. Sam opened discussing the purpose of turbine overspeed protection. It’s required for personnel safety and machinery protection against overspeed condition.

At the 2019 Ovation Users’ Group conference, Emerson’s Sam Onuska and Greg Lieb provided an update on turbine overspeed protection in Ovation distributed control systems. Sam opened discussing the purpose of turbine overspeed protection. It’s required for personnel safety and machinery protection against overspeed condition.

Overspeed protection is applied to steam turbines, boiler feed pump turbines, combustion turbines and hydro turbines. The components common to all overspeed protection systems are a method of measuring shaft rotational speed, fast decision-making capability, action taken based on the decision, and a result in reducing turbine rotational velocity.

Mechanical overspeed protection systems have eccentric weight retained in the turbine shaft by a preset spring force. When the rotation speed exceeds the spring force the eccentric weight extends from the shaft, striking a trip lever, trip lever rotates, releasing a spring-loaded plunger, opening a hydraulic connection to atmosphere, depressurizing a hydraulic header – which typically closes valves.

When switching over to an electronic overspeed protection system, the motor mounted equipment is not typically removed, but trip lever and all associated linkages, hydraulic trip valve, pressure switches, and tubing & piping associated with the mechanical overspeed trip are removed.

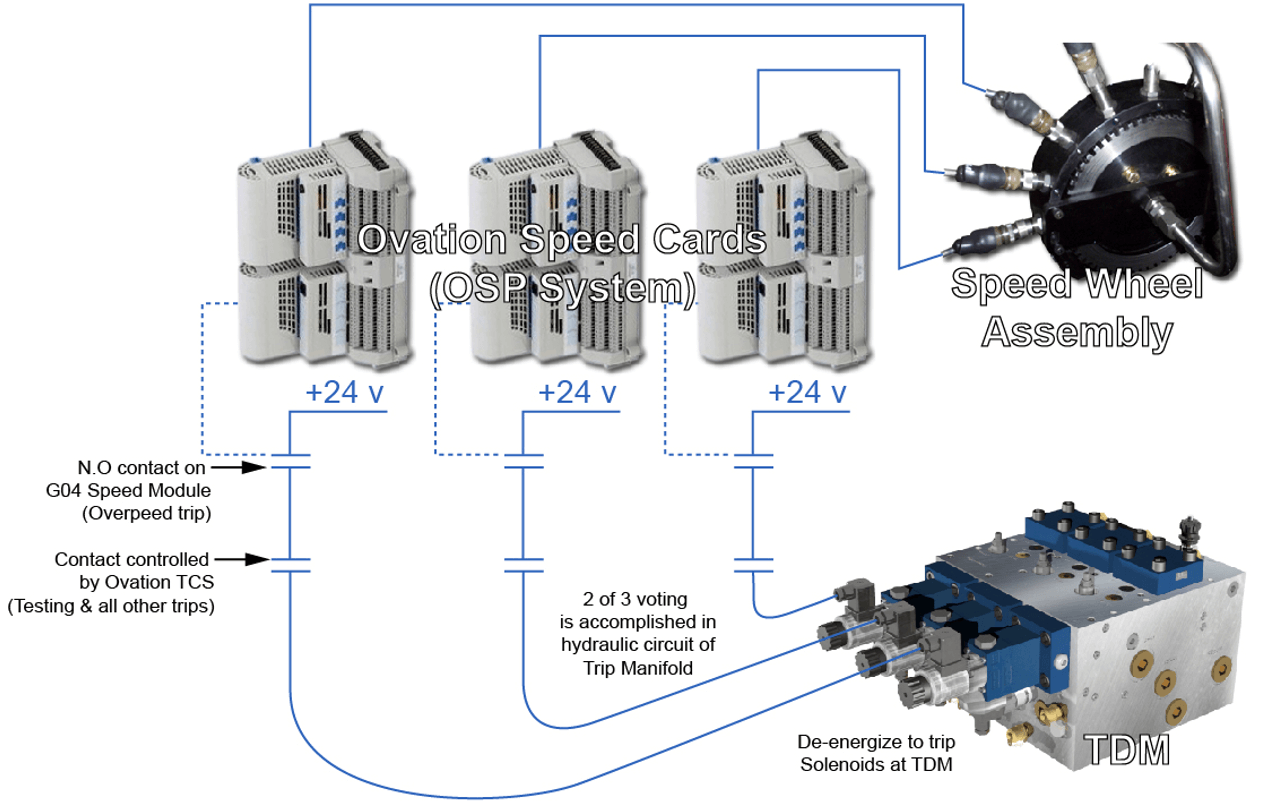

In an electronic overspeed protection system, shaft rotational speed is measured by Eddy current, Hall-Effect or Variable Reluctance probes, which require a ferrous target (wheel) on the rotating component. The pulse train (active) or sine wave (passive) signal is converted to rotational speed and a processor compares calculated speed to a setpoint. If the setpoint is exceeded a relay is opened or closed. Outputs from the system can configured in a non-voted or voted (typically 2oo3) arrangement depending on the application.

Testing of the overspeed protection system can done as a reduced or actual test. The reduced test lowers the trip setpoint for test, which minimizes stresses caused by actual overspeed tests. The actual test uses the same trip setpoint for normal operation, which tests integrity of the entire trip circuit.

The Testable Dump Manifold (TDM) trip functionality uses solenoid operated directional valves that rapidly de-pressurize turbine trip headers. Two sets of redundant valves provide increased reliability, and on-line testability of the main turbine trip functions. The entire test sequence can be fully automated in the controller.

The general guidelines for an electronic overspeed protection system include detection prior to 110-112% rated speed. The reaction time for this condition should be less than 40ms (per API 670). The module configuration, sampling rate, and rotor acceleration influence this reaction time. For the Ovation Overspeed Protection system this response time is typically 13-25ms. The total system response consists of overspeed detection, trip signal to hydraulic system and hydraulic actuator / valve closure.

The advantages of electronic overspeed protection systems from a maintenance perspective are no moving parts and spare parts are commonly available I/O modules, speed sensors, solenoid valves versus custom fabricated components. From a testing perspective there is no loss of production, the turbine is not placed in an unsafe condition. Overspeed setpoints can be modified in logic versus mechanical adjustments. And from a troubleshooting perspective, data is available for live viewing and historical analysis. Fault tolerance is also available through redundancy.

Visit the Mechanical Solutions section on Emerson.com for more on electronic overspeed protection systems and other solutions for optimal turbine performance.