Partial stroke test is one of the viable means to check mechanical integrity of Final Element of Safety Instrumented Function (SIF) loop. Generally, end users struggle on question of credit of PST for improvement in SIL (Safety Integrity Level).

IEC 61508 and IEC 61511 define diagnostic coverage factors (DCF), but do not provide a prescriptive way to estimate the number applied in real process applications.

Diagnostic coverage (DC) as defined in IEC 61511 is ratio of the detected failure rate to the total failure rate of the component or subsystem as detected by diagnostic tests. Diagnostic coverage does not include any faults detected by proof tests.

For safety applications the diagnostic coverage is typically applied to the safe and dangerous failures of a component or subsystem. For example, the diagnostic coverage for the dangerous failures of a component or subsystem is DC = λDD / λDT , where λDD is the dangerous detected failure rate and λDT is the total dangerous failure rate (Dangerous Detected and Dangerous Undetected).

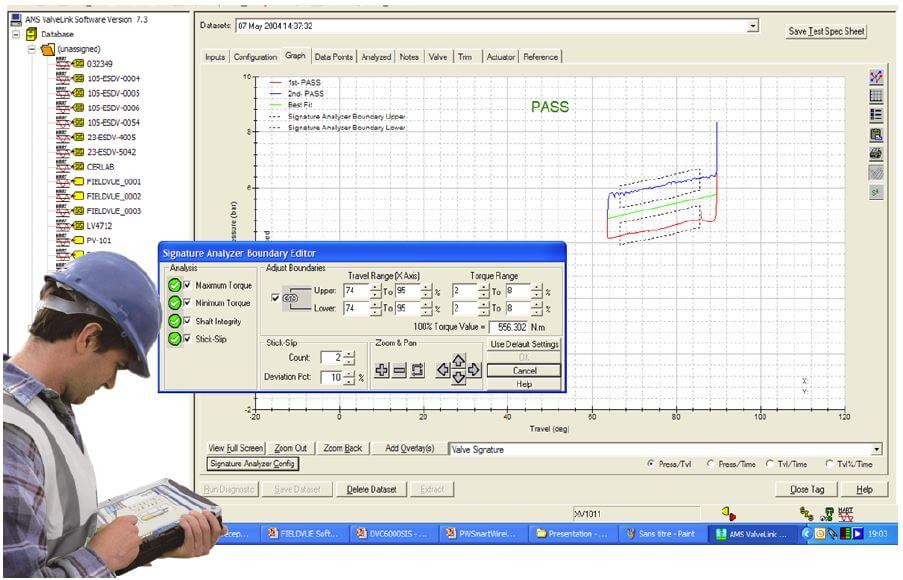

Let’s look at factors to be considered in estimating diagnostic coverage factors, DCF’s, required for calculating Probability of Failure on Demand (PFDavg) for the “final control element” when an online partial stroke test is initiated by the digital valve controller:

PFDavg = λDU x DC x Test Interval PST / 2 + λDU x (1-DC) x Test Interval FST / 2

Note: λDU is Dangerous undetected failure rate. PST is partial stroke test and FST is full stroke test.

The diagnostic coverage factor is a function of applications, process fluid, physical properties of fluid, operation history, maintenance records, environmental conditions, test philosophy, etc. A complete valve assembly needs to be considered in order to find the failure mode effect and diagnostic analysis (FMEDA) to help determine type of failures, which can be established by a partial stroke test.

However, although a 70% coverage factor is very common and used by various consultants and engineering companies, it has to be evaluated in light of the application. If the valve is fully open during normal operation, then partial stroke tests will not examine for a tight shut off.

For a fully open valve during normal operation when the process fluid is such that it starts coagulating or polymerizing at the valve seat, partial stroke tests will not detect it. The type of service, dirty or clean, will also affect the DC factor. If fluid is flammable or toxic and tight shut off is a must, then the DC factor by partial stroke will go quite low.

As a manufacturer, Emerson will restrict the DC factor to a maximum of 70%, but depending upon the application specifics, it can go lower. Take a look at this typical PFDavg calculation for a better understanding of the diagnostics coverage factor effect.

Consultants generally recommend that the DC factor should be between 70 -80%, but they direct customers towards process and application related guides before making a final decision.

A partial stroke test by a FIELDVUE digital valve controller can possibly detect the following issues with the final control element:

- Shaft/stem misalignment

- Packing fraction

- Leak in pneumatic system (pressurized path including tubing, fittings, actuators, etc.)

- Leak in supply pressure

- Plug – cage galling (asymmetric travel)

- Linkage connections between shaft and digital valve controller

- Shaft bearing wear out/torque requirement

- Connection between actuator shaft and plug shaft

- Broken spring or permanent set of spring

Using the above information, a suitable FMEDA report can be prepared for individual applications. It can provide a better guide for selecting proper DC numbers for comparison of the numbers that are based on mechanical components or theoretical generic numbers.

Generally, in the “realization phase” of the safety life cycle, after selecting the technology and architecture, the test frequency needs to be established. During this time, the FMEDA exercise will provide the DCF number, which can then be used to determine the test frequencies (offline or online).

From Jim: Visit the Digital Valve Controllers area on Emerson.com for more on their use in safety instrumented systems. You can also connect and interact with process safety experts in the Control & Safety Systems group on Emerson.com.